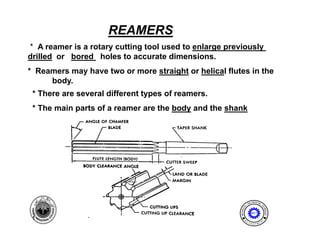

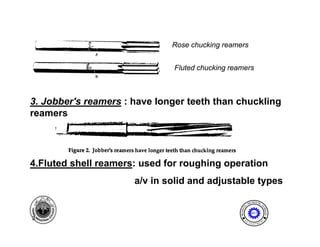

A reamer is a rotary cutting tool used to enlarge previously drilled or bored holes to accurate dimensions. There are several types of reamers including machine reamers like rose chucking and fluted chucking reamers, and hand reamers made of high-speed steel or carbon steel. Proper reaming techniques involve using the correct speed and feed rate, applying a cutting fluid, and avoiding practices like letting the reamer chatter or turning it backward.