1. Refrigeration involves extracting heat from a body to maintain it at a lower temperature than its surroundings. Air conditioning provides thermal comfort by controlling temperature and humidity.

2. A refrigeration system uses a refrigerant to absorb heat from a cold space and reject it to a hot space. Common components are an evaporator, compressor, condenser, and expansion valve. The refrigerant undergoes phase changes between gas and liquid.

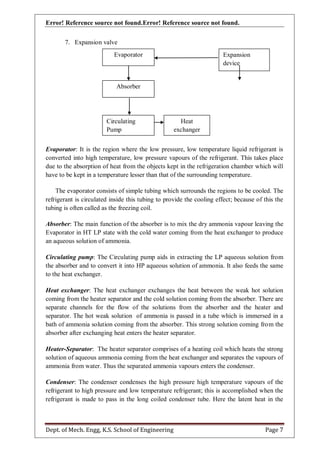

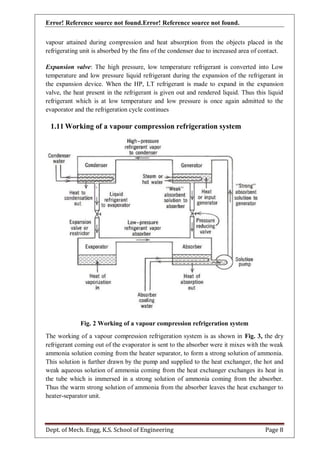

3. Vapour compression and vapour absorption are two main refrigeration cycles. Vapour compression uses a compressor to raise the refrigerant's pressure and temperature before condensing. Vapour absorption relies on chemical reactions between a refrigerant and absorbent like ammonia and water.