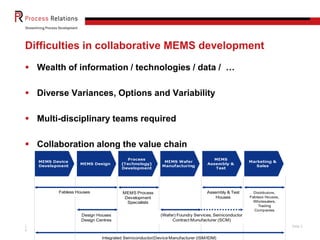

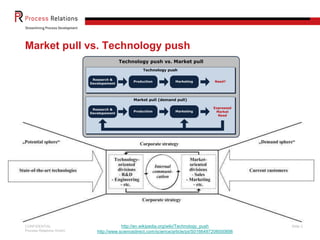

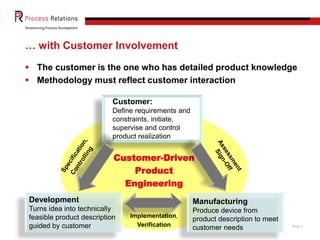

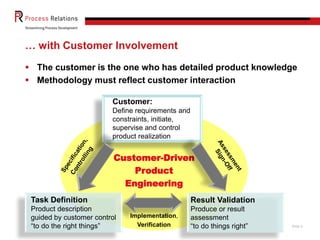

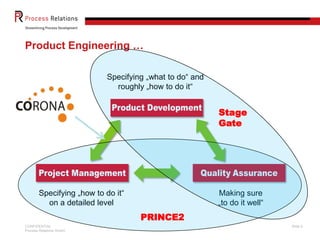

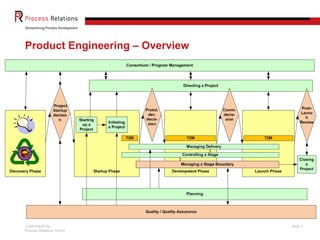

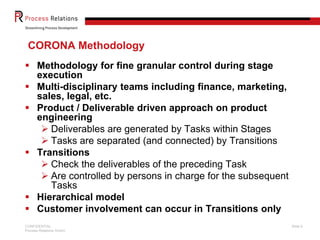

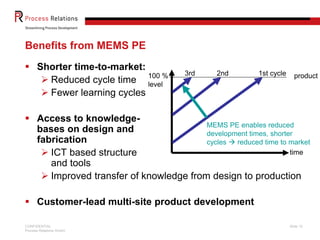

The document discusses challenges and methodologies in MEMS product engineering, emphasizing the need for customer involvement and collaboration among multi-disciplinary teams. It outlines the importance of methodologies such as stage-gate and PRINCE2 for effective project management and highlights the benefits of shortened time-to-market through improved knowledge transfer. The document concludes that combining tailored methodologies can help navigate the complexities of MEMS product development.