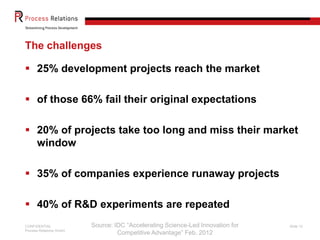

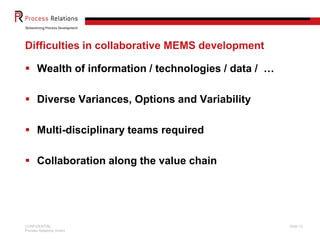

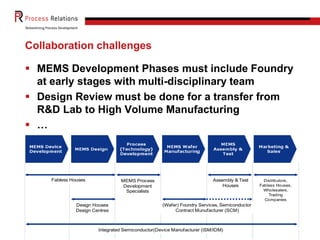

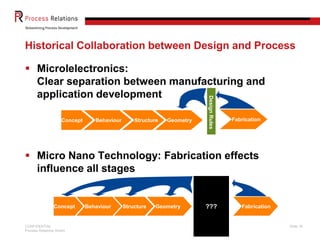

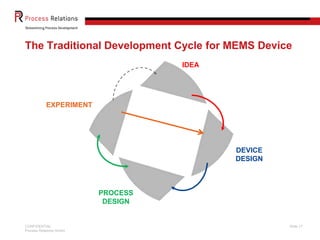

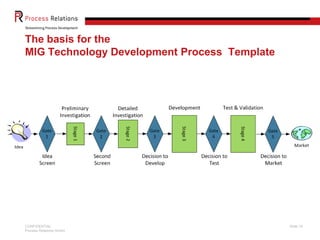

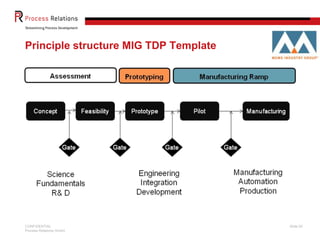

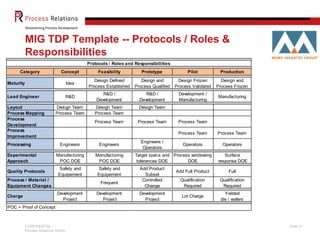

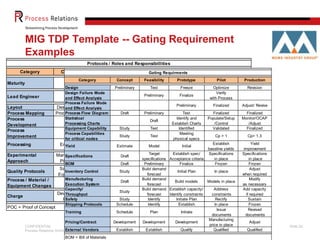

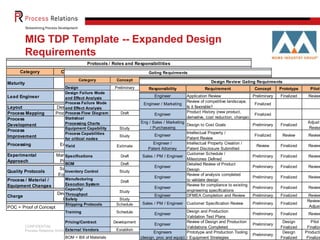

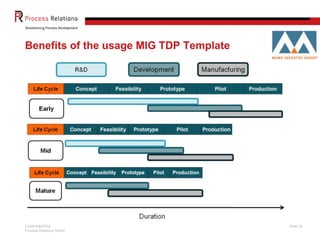

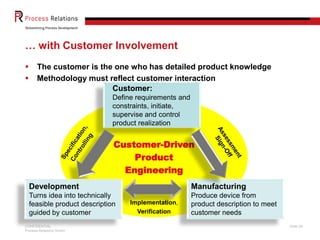

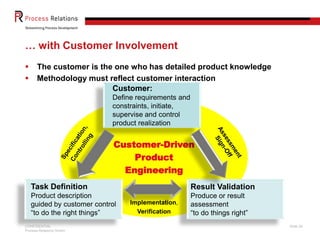

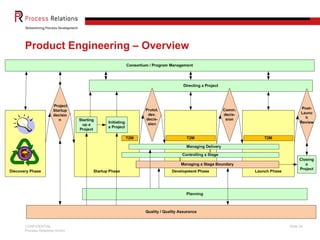

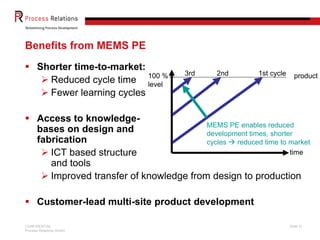

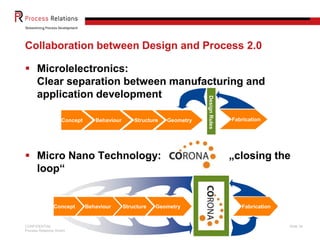

The document discusses challenges in MEMS development collaboration and proposes solutions. It describes the MEMS Industry Group's Technology Development Process template, which provides guidelines for multi-site, multi-disciplinary collaboration. It also discusses the CORONA methodology, which emphasizes customer involvement for shorter development times. The conclusions are that adopting collaboration methodologies and best practices can help overcome challenges and that new approaches to data exchange and infrastructure are needed.