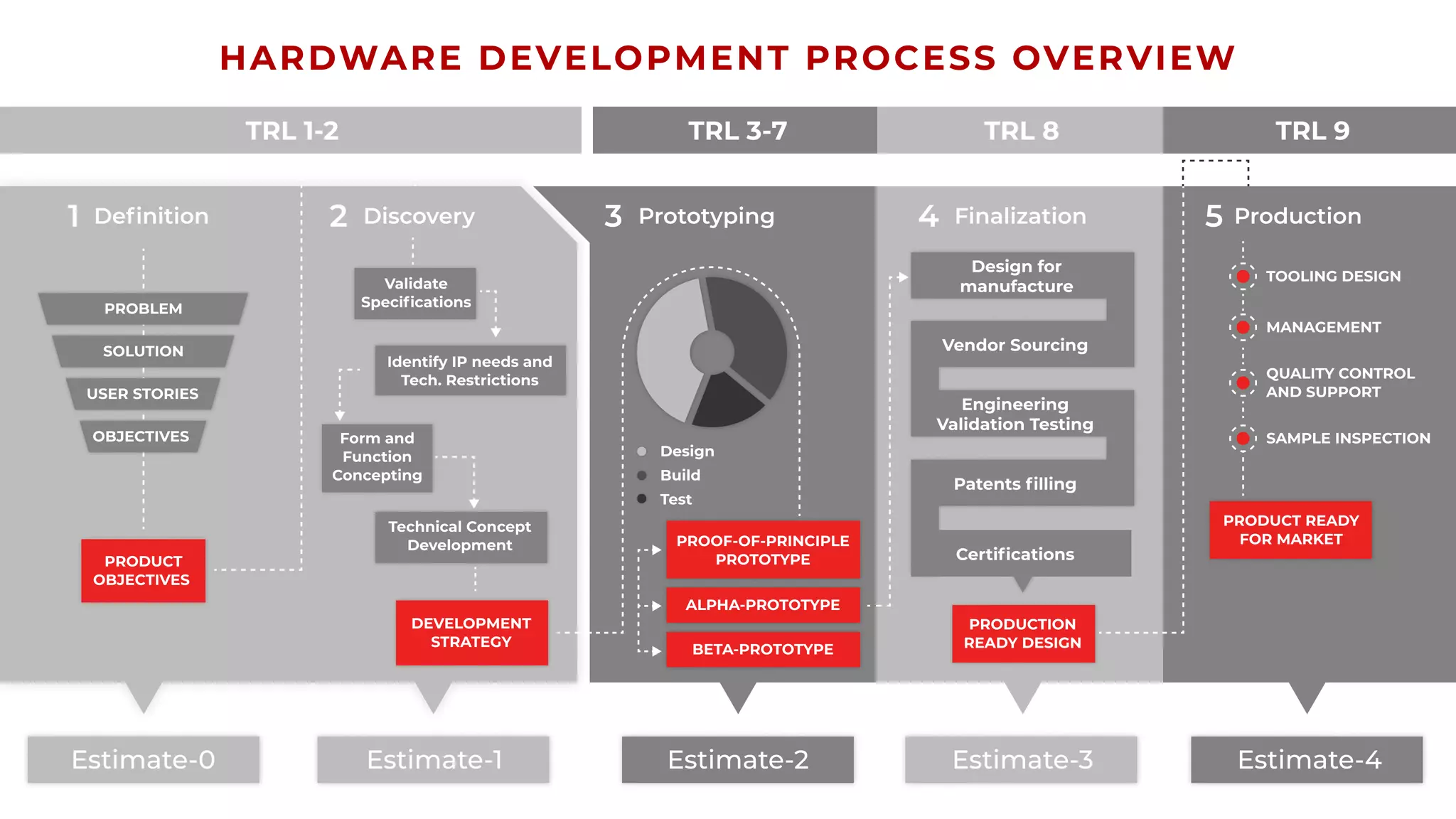

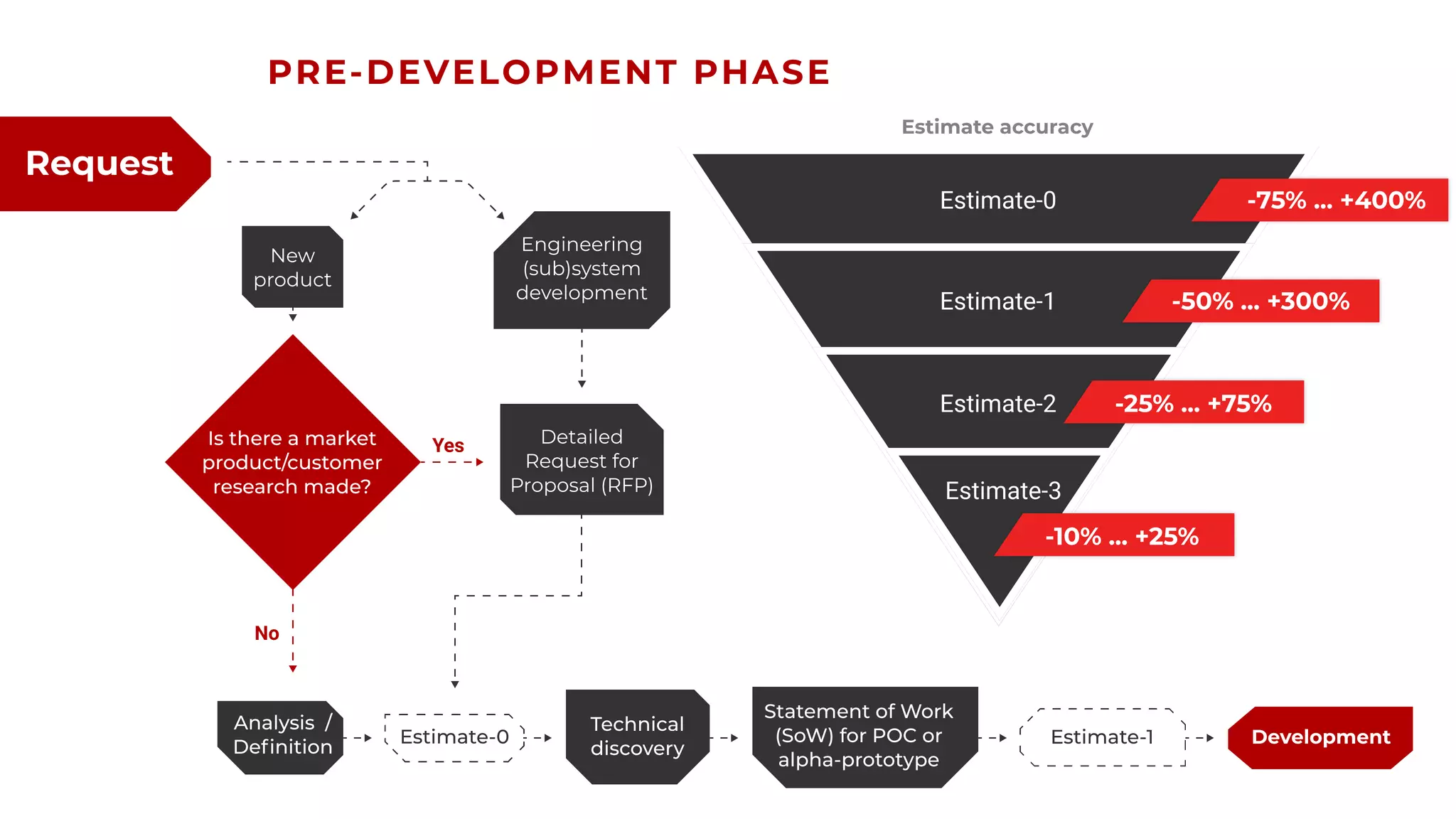

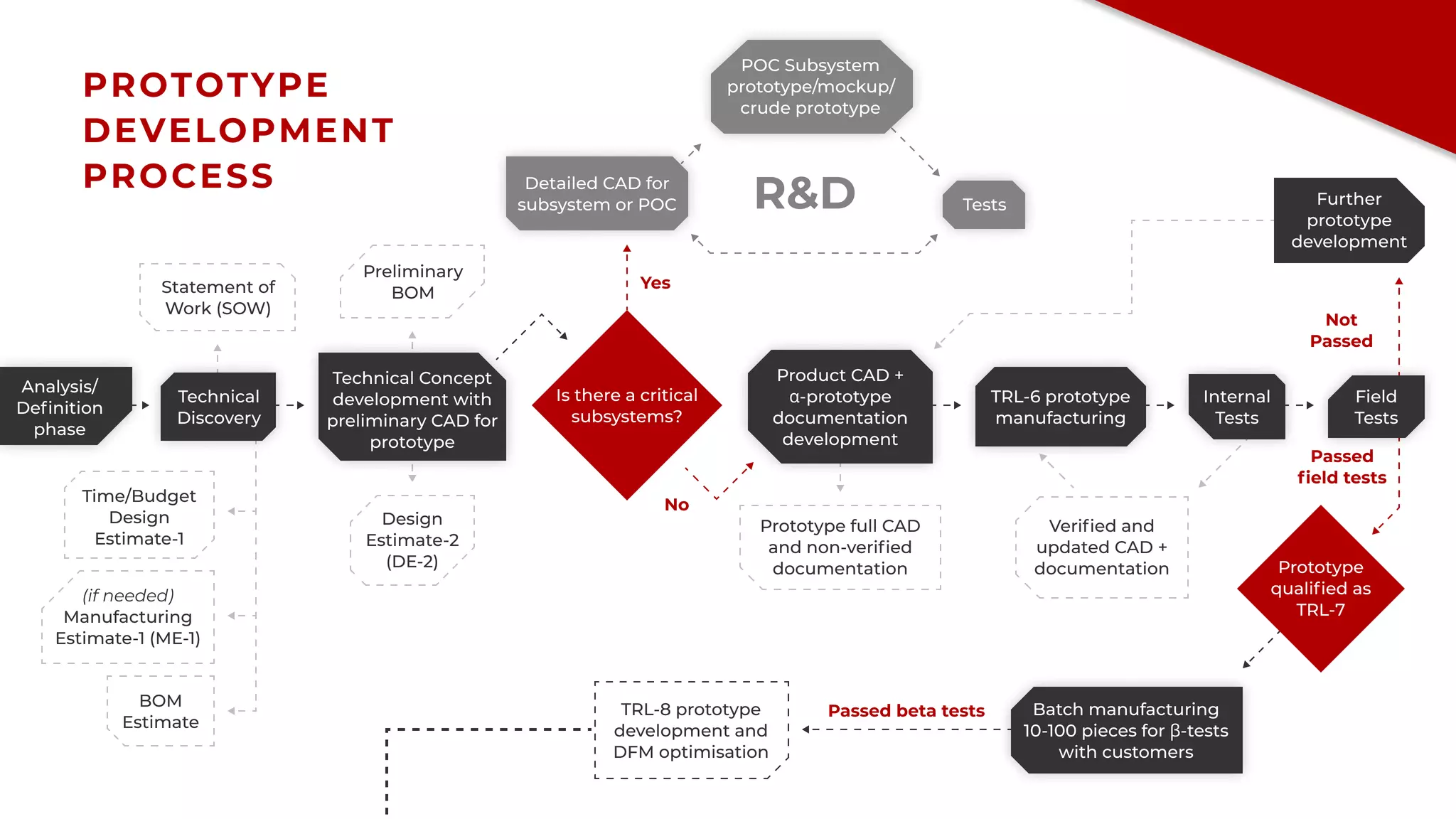

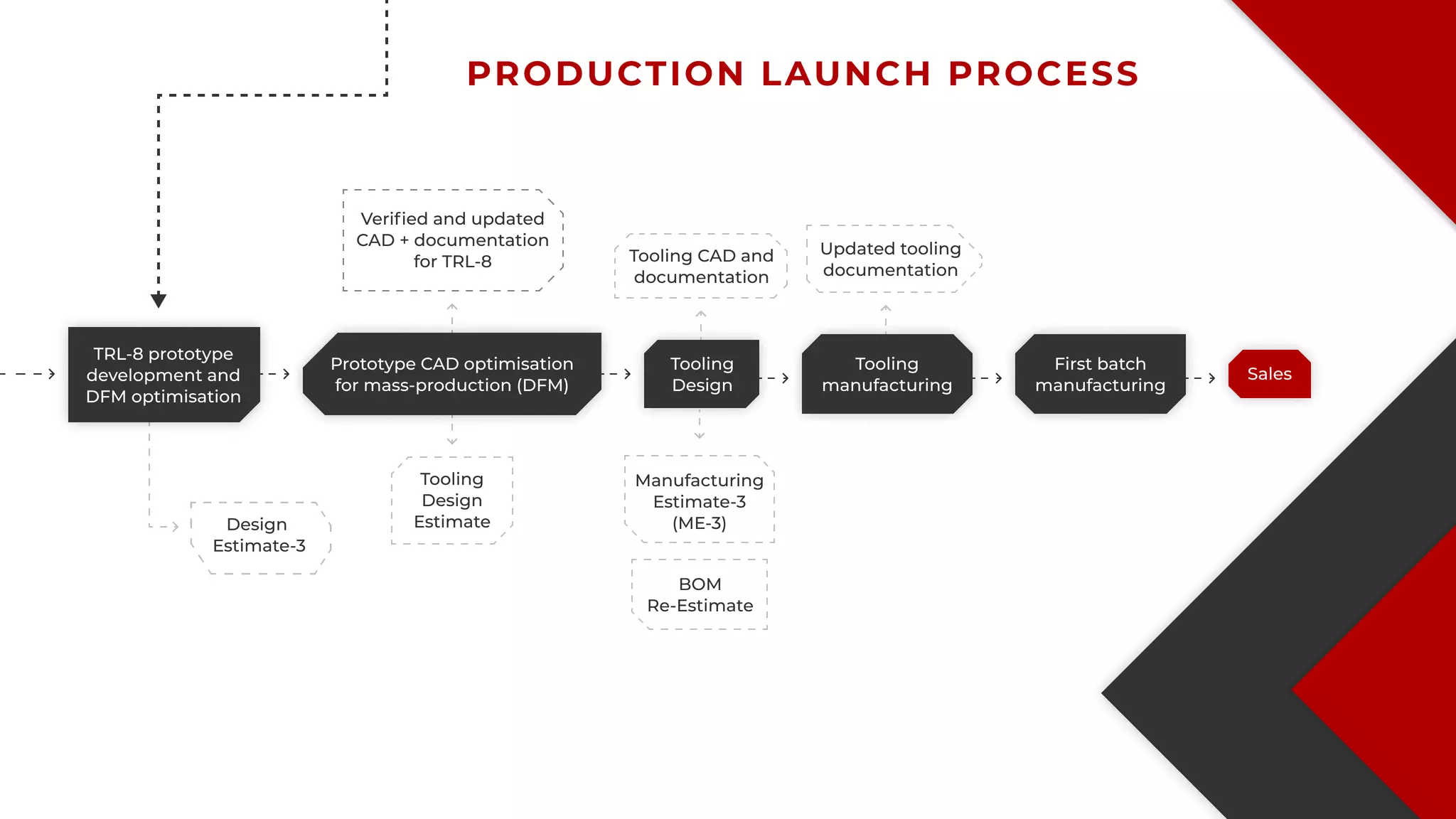

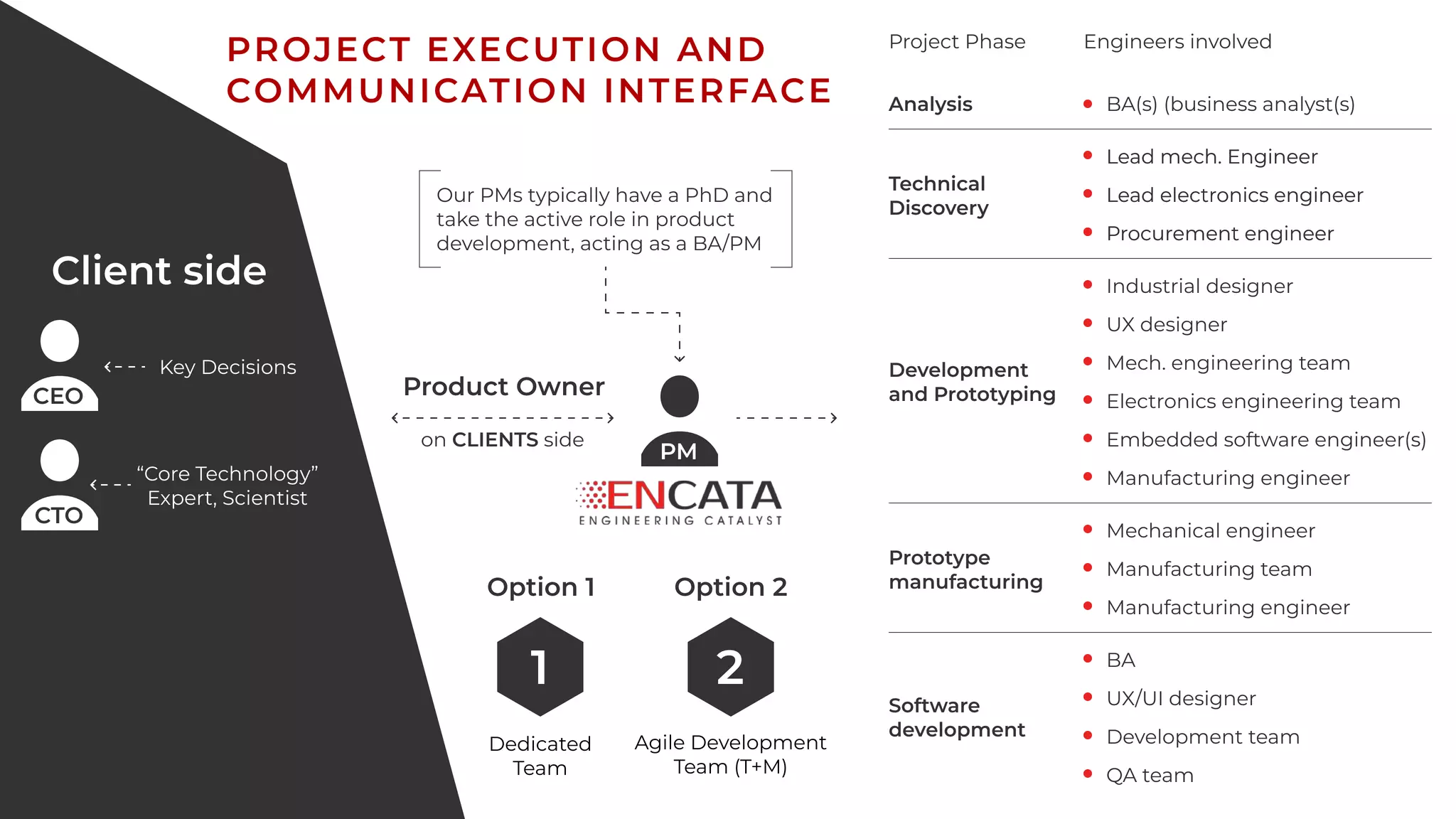

The document provides an extensive overview of a product development process, including stages such as market and customer research, technical discovery, and prototype development. It details various phases of the development lifecycle, from initial concept to production, emphasizing the need for accurate estimates and testing to ensure product viability. Key roles and decision-making processes are also highlighted, outlining the collaborative approach taken throughout the project.

![1 2 3 4 5

Definition/Analysis

Technical Discovery

Development

and Prototyping

Tests

Finalization = TRL-8

Problem definition,

solution, user stories,

development objectives

Specification dev., technical benchmarking,

form and function technical concepting,

TRIZ, detailed development strategy

for parts and [sub]system

(design-for manufacturing,

engineering validation tests,

certification, batch production)

1. Requirements

discovery

2. Requirements

classification and

organization

R&D

3. Requirements

prioritization and

negotiation

4. Requirements

specification

TRL-X Prototype

Further

development

and changes

TRL-5: subsystems are designed and working as required

TRL-4: Proof-of-Principle prototype / demonstrator

TRL-6: a good looking “polished” α-prototype

TRL-7: the α-prototype has passed “field tests” and is working

EnDevelopment process practiced in Cata](https://image.slidesharecdn.com/encataprocesspresentation-200131085630/75/EnCata-Process-Explained-6-2048.jpg)