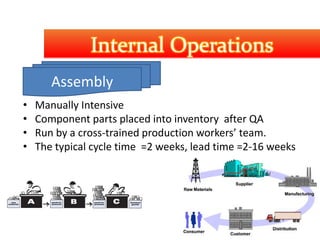

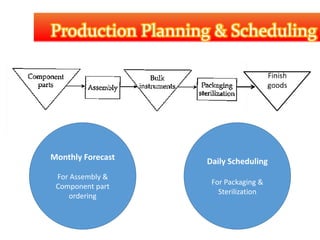

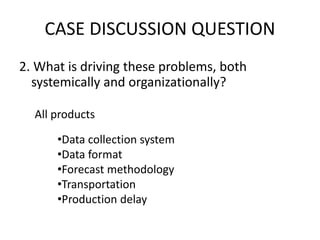

Meditech Surgical faces problems with new product introductions and delivering all products on time. New products experience high initial demand that is difficult to forecast, resulting in delays. All products suffer from inconsistent data collection systems, long production lead times, and a siloed organizational structure. The customer service manager first recognized these issues as they directly interact with unhappy customers experiencing delays. To solve the problems, Meditech should reduce complexity, implement demand pooling, standardize data sharing between departments, outsource low-margin products, and improve forecasting methods.