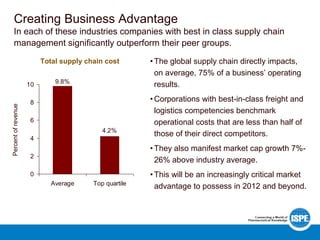

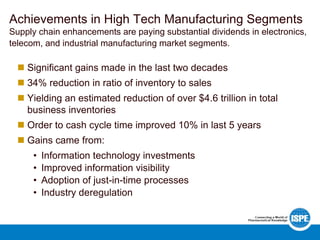

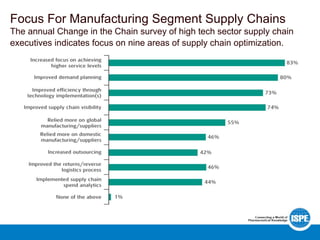

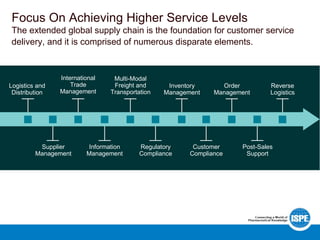

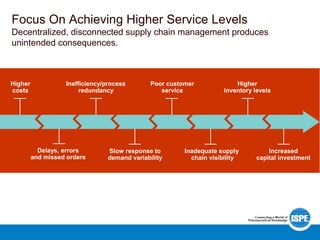

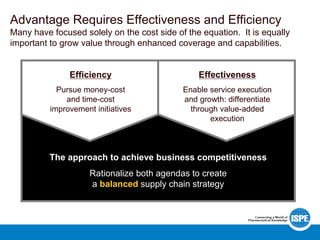

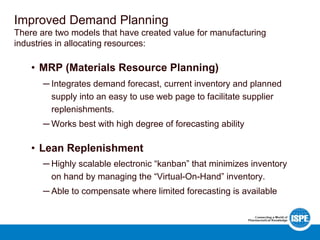

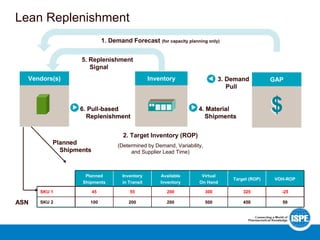

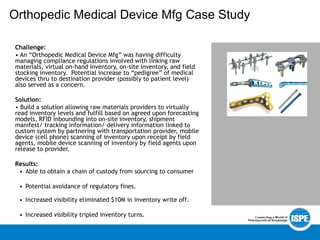

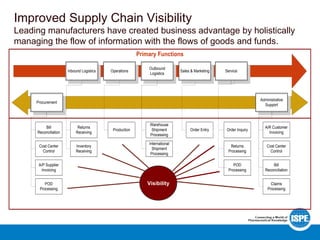

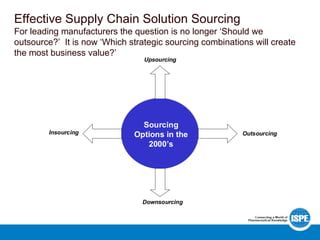

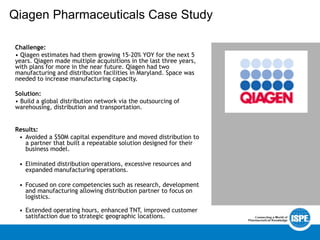

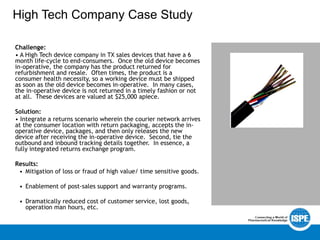

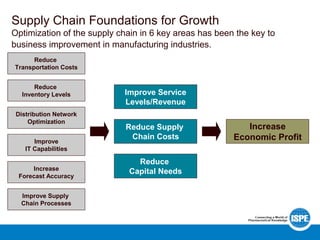

This document discusses supply chain improvements and case studies. It begins with an overview of UPS's industry segmentation approach and focus on supply chains for high tech and manufacturing. It then discusses three case studies showing how improved demand planning, supply chain visibility, and international trade management helped companies address challenges and achieve results like avoiding fines and increased inventory turns. The document concludes that optimization in areas like reducing costs, improving processes, and forecast accuracy are foundations for business growth.