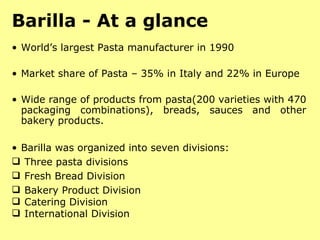

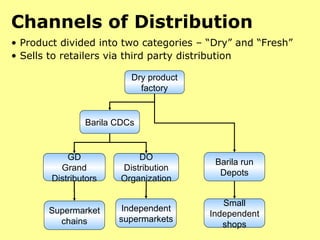

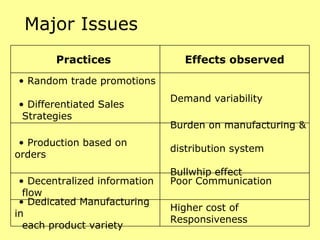

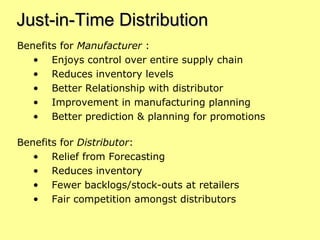

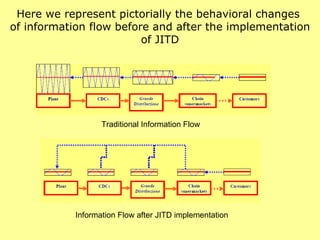

Barilla is the largest pasta manufacturer in the world with a 35% market share in Italy and 22% in Europe. It produces over 200 varieties of pasta along with other bakery products. The company was organized into several divisions but faced issues with poor communication, decentralized information flow, and inconsistent sales strategies. This led to thinning margins. To address this, the Director of Logistics proposed implementing a Just-in-Time Distribution system to improve demand forecasting, reduce inventory levels, and strengthen relationships between Barilla and distributors. However, the change faced resistance from some distributors and internal departments.