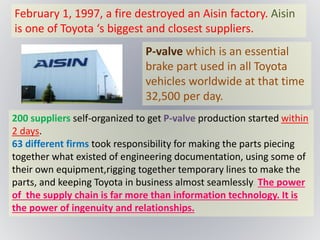

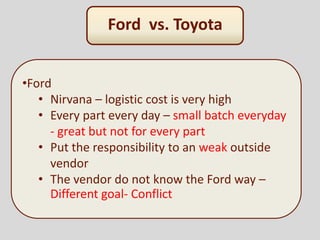

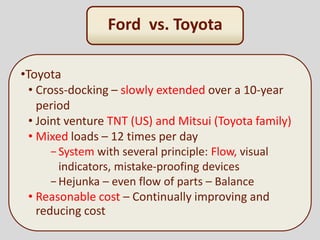

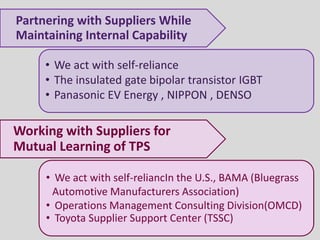

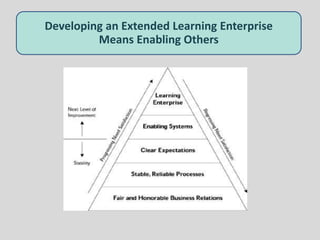

This document discusses Toyota's approach to developing strong partnerships with suppliers. It provides examples of how Toyota invests in suppliers to help them improve, such as through the Supplier Improvement Committee that helps "sick" suppliers address issues. The document also contrasts Toyota's approach with Ford's, noting that Toyota takes more responsibility for the supply chain and engages in continual improvement efforts with suppliers, while Ford had higher logistic costs and put more responsibility on weaker vendors. Finally, it discusses how Toyota maintains internal capability while partnering with suppliers through initiatives like joint ventures and working with suppliers on mutual learning of Toyota Production System principles.