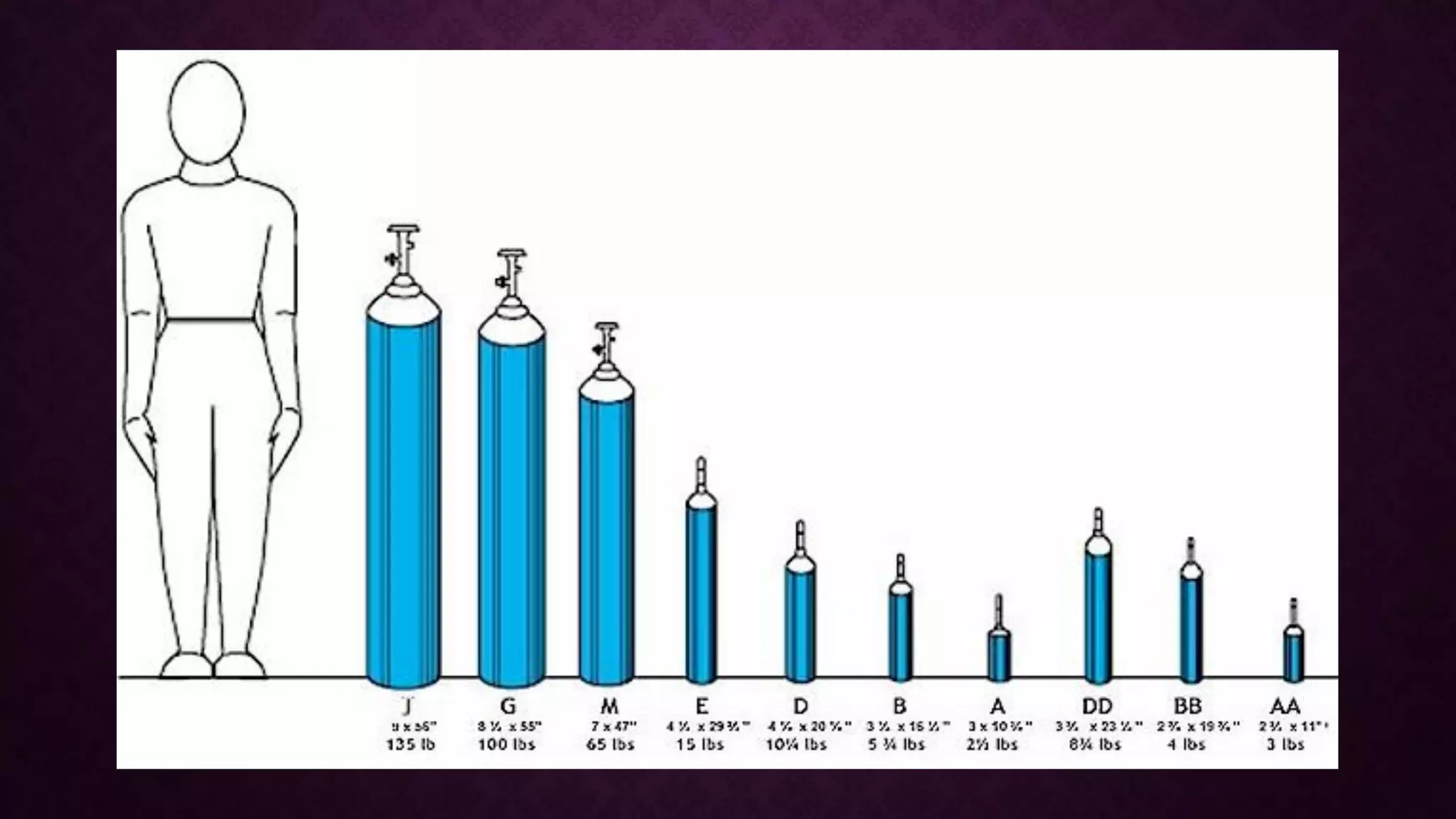

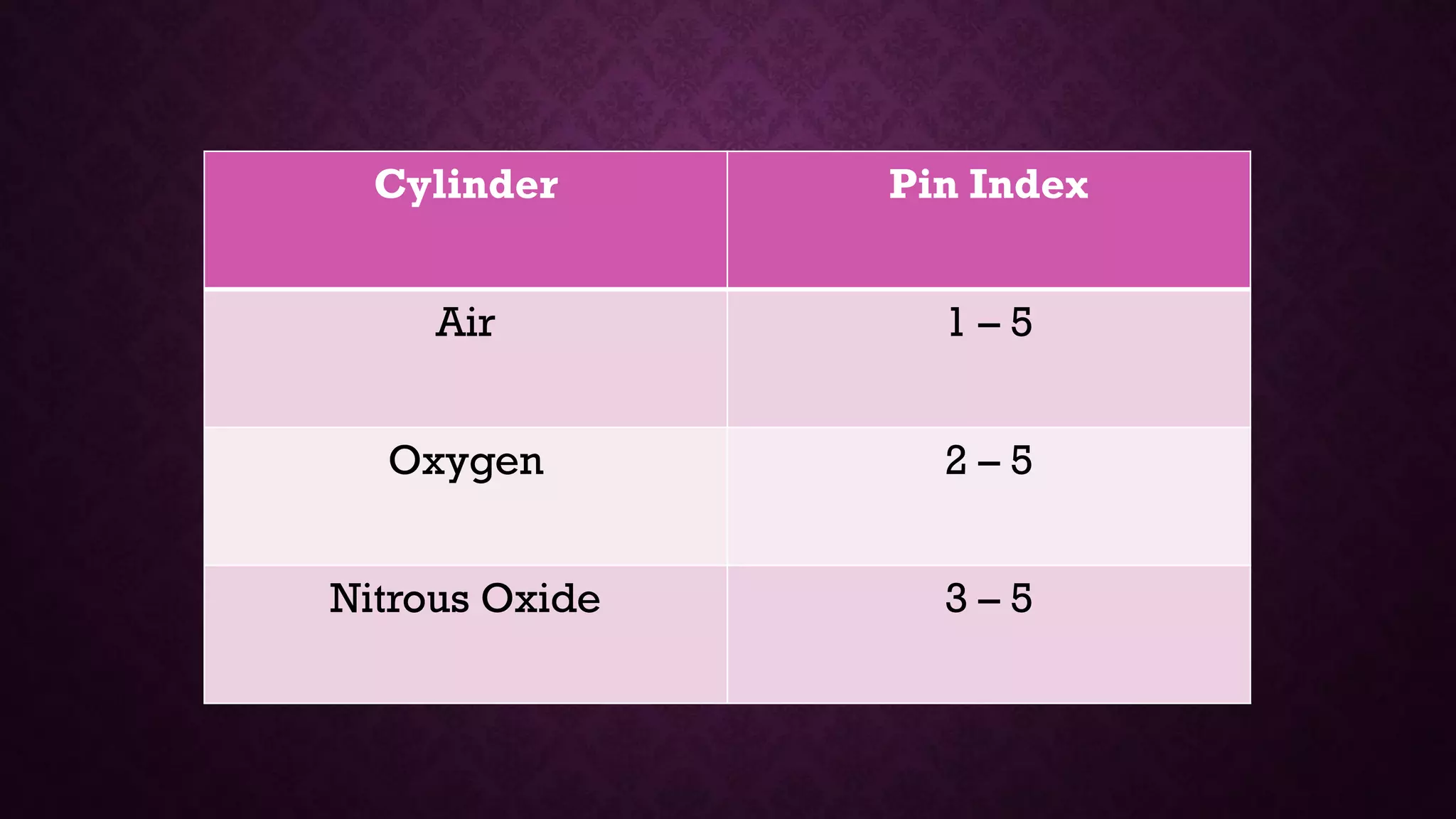

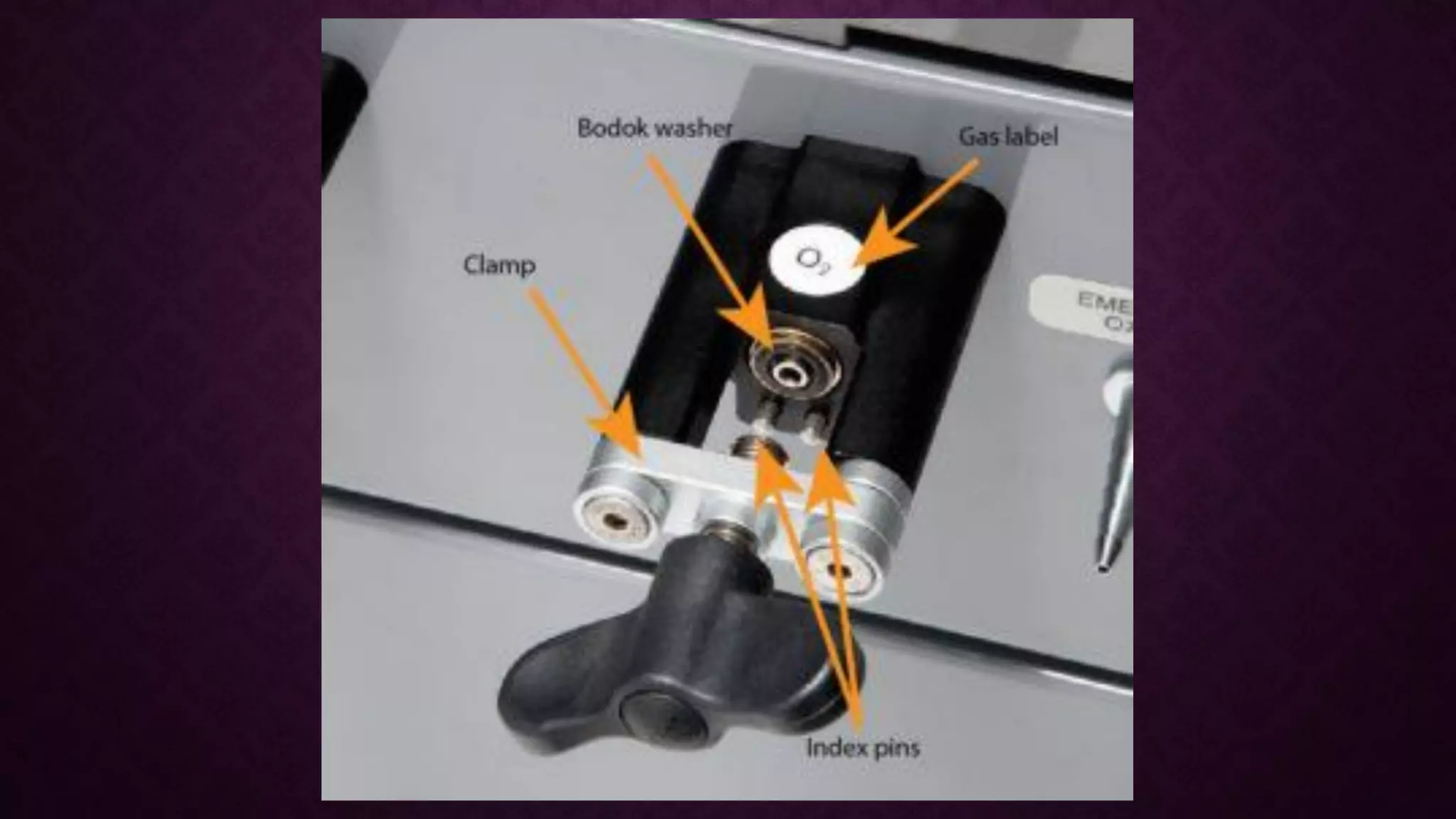

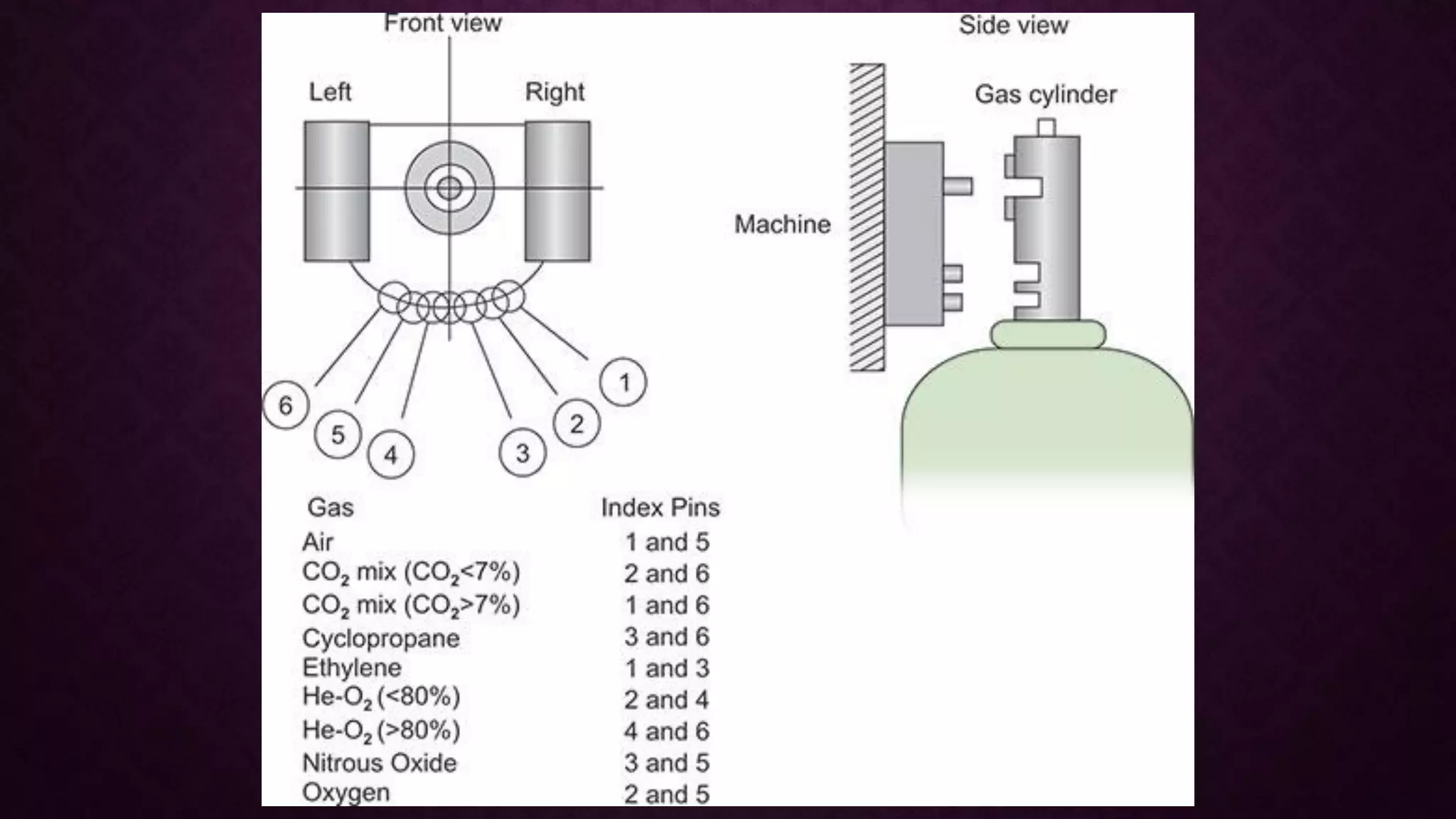

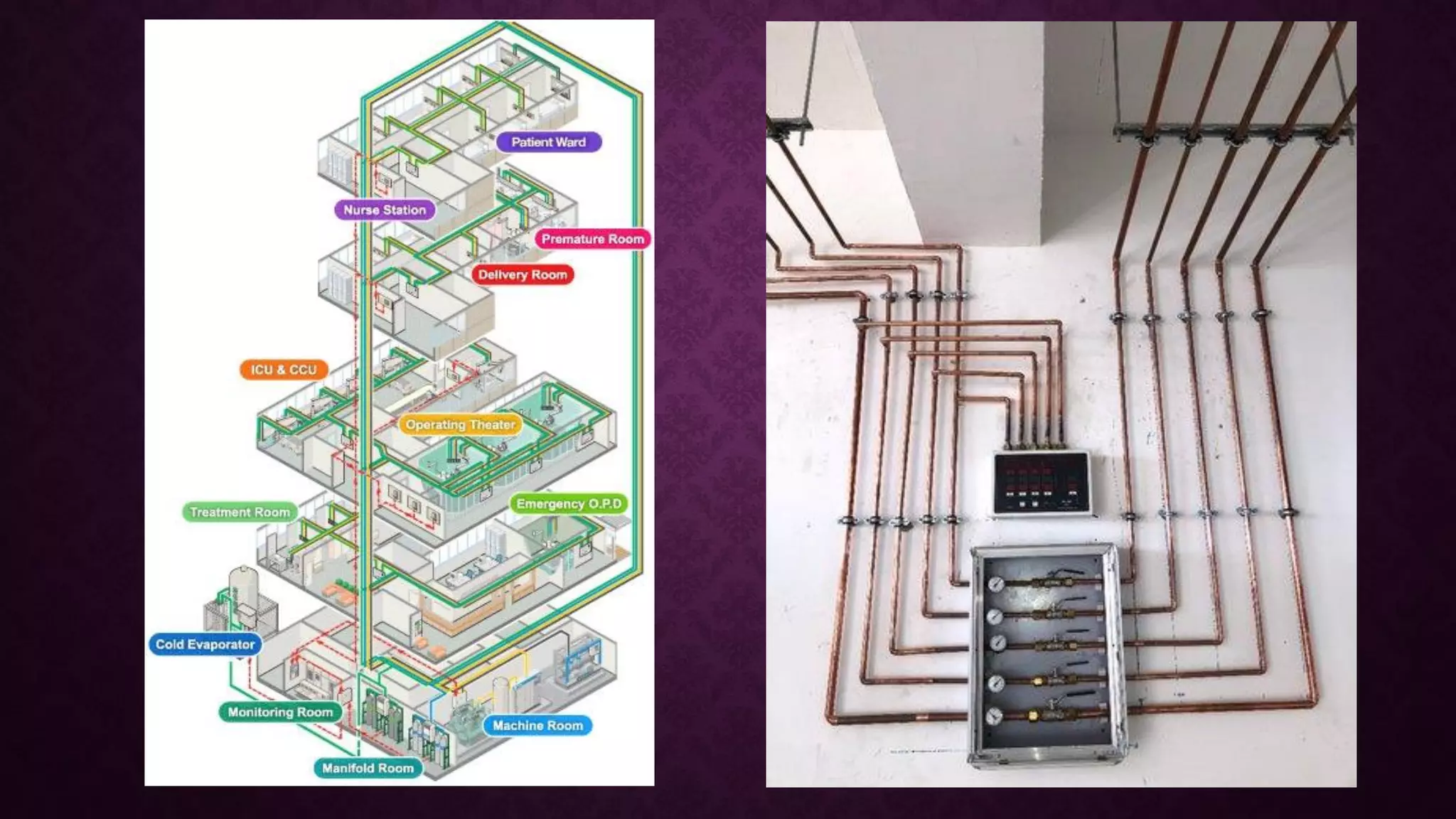

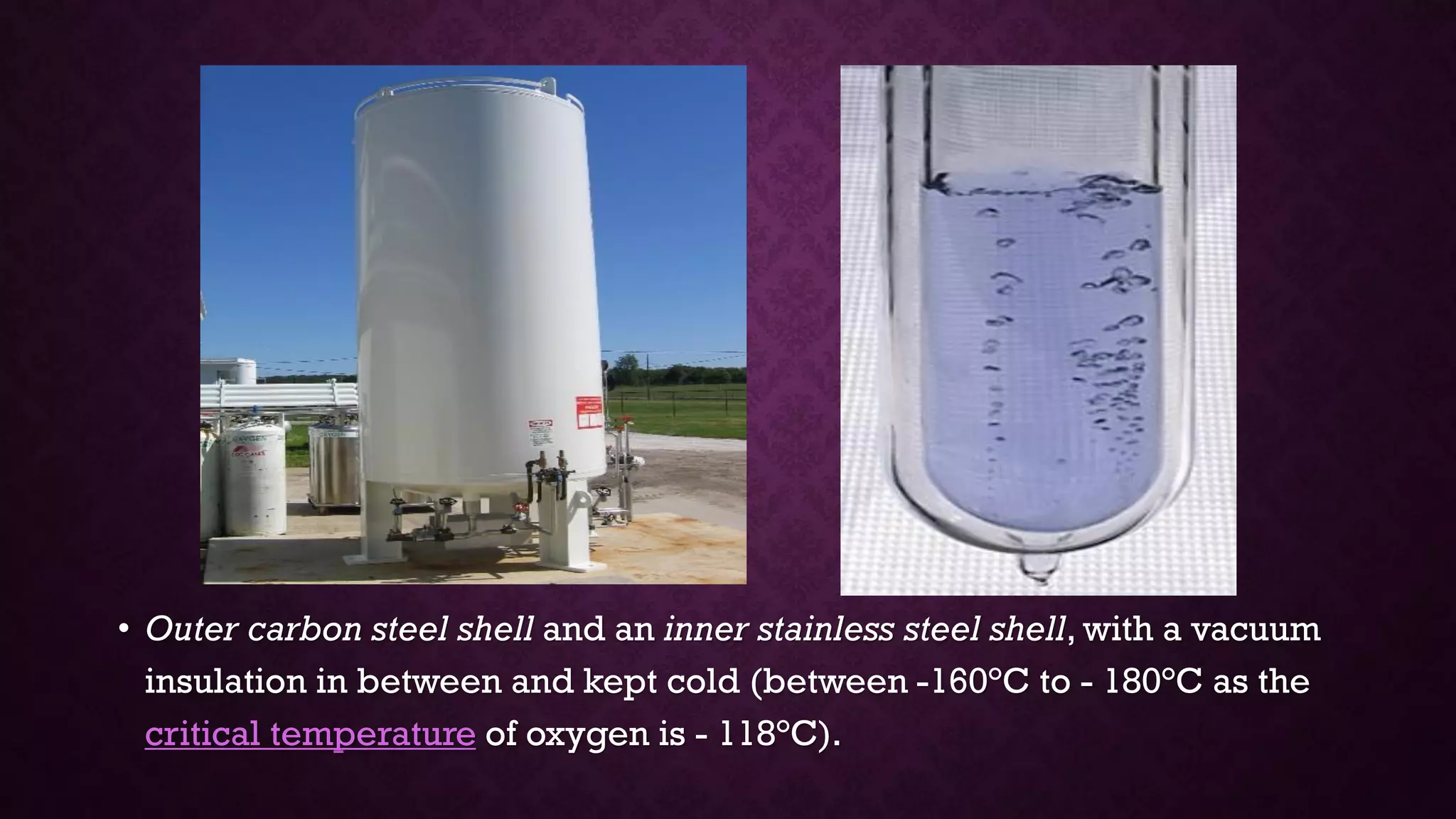

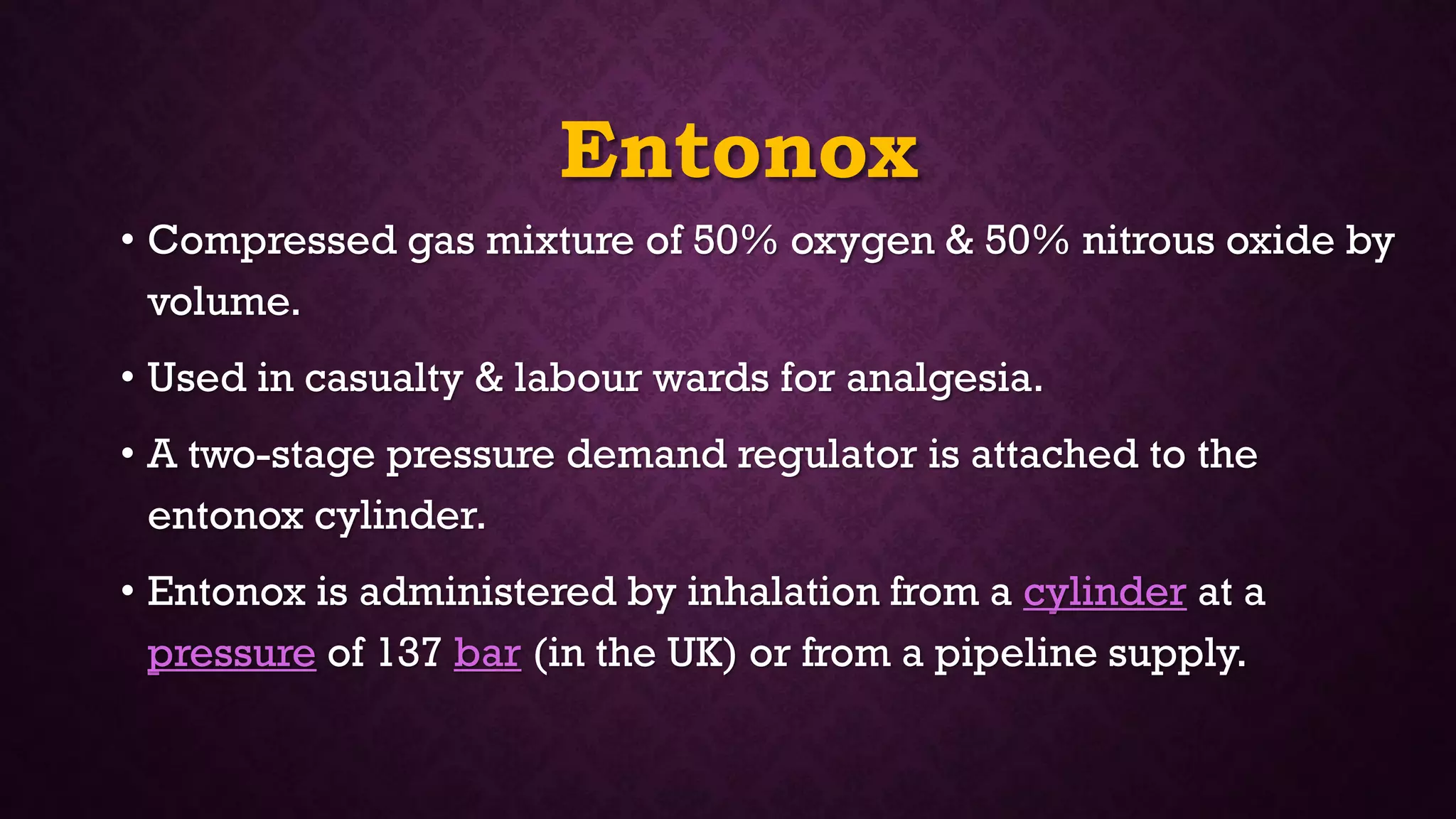

Medical gas supply systems in healthcare facilities provide specialized gases, including oxygen and nitrous oxide, through cylinders and piped systems. Cylinders are manufactured in various sizes, marked for safety, storage, and usage information, and must be stored correctly to prevent hazards. The document outlines the safety features, components, and operational mechanisms of medical gas systems, including cylinder designs, labeling, and piped gas delivery systems.