This document provides a comprehensive overview of centrifugal pumps, including their purpose, various types, and key considerations for selection such as capacity, differential pressure, and fluid characteristics. It details specific pump designs, materials, bearing types, lubrication requirements, and performance evaluations necessary for proper operation and efficiency. A focus is also placed on maintenance considerations and the factors influencing pump reliability and longevity.

![24

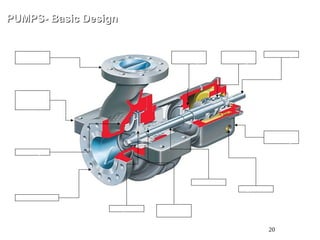

PUMPS- Basic Design

PUMPS- Basic Design

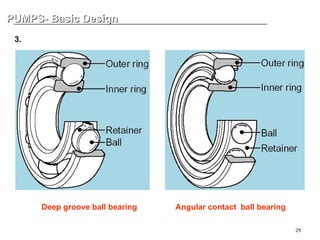

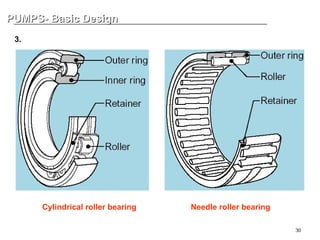

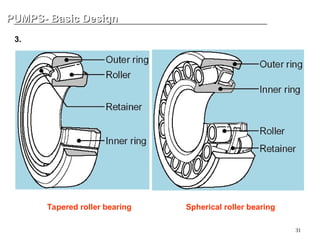

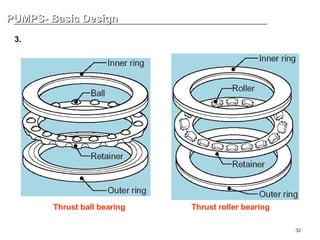

3. Bearing

Condition Bearing type and arrangement

Radial and thrust bearing speed and life within limits for

rolling element bearings and Pump energy density

below limit

Rolling-element radial and thrust

Radial bearing speed or life outside limits for rolling-

element bearings and Thrust bearing speed and life

within limits And Pump energy density below limit

Hydrodynamic radial and rolling-element thrust

or

Hydrodynamic radial and thrust

Radial bearing speed or life outside limits for rolling-

element bearings and Thrust bearing speed and life

within limits And Pump energy density above limit

Hydrodynamic radial and thrust

Limits are as follows.

a) Rolling-element bearing speed: Factor, n.dm shall not exceed 500 000 where

dm is the mean bearing diameter [(d + D)/2)], expressed in millimetres;

n is the rotational speed, expressed in revolutions per minute.

b) Rolling-element bearing life: basic rating life, L10, in accordance with ISO 281, equivalent to at

least 25 000 h with continuous operation at rated conditions, and at least 16 000 h at maximum

radial and axial loads and rated speed.

c) Hydrodynamic radial and thrust bearings shall be used if the energy density [i.e. the product of

pump rated power, kW (hp), and rated speed, r/min] is 4,0 × 106

kW/min (5,4 × 106

hp/min) or

greater.](https://image.slidesharecdn.com/centrifugalpumptraining-241229091157-ed4cf175/85/Basic-Centrifugal-Pump-Training-presentation-24-320.jpg)