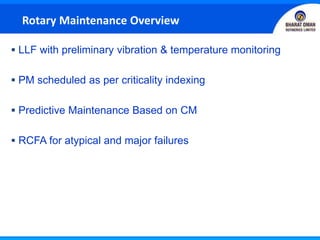

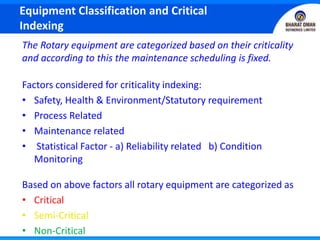

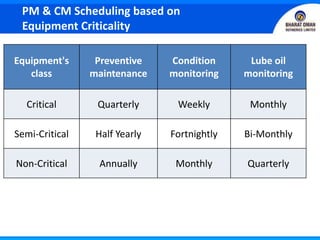

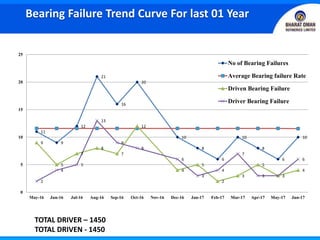

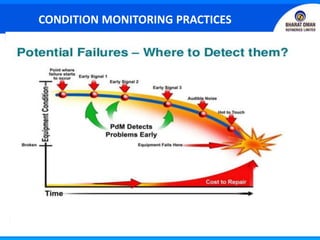

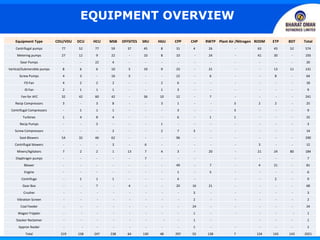

The document outlines the maintenance practices and performance overview of rotary and static equipment at BORL, emphasizing the optimization of maintenance costs and enhancement of equipment reliability. It details the structure of mechanical maintenance, condition monitoring practices, and the categorization of equipment based on criticality. Key achievements include improved lubrication reliability, maintenance innovations, and proactive maintenance programs that have significantly reduced seal and bearing failures.