This document discusses the classification, properties, and design considerations for timber used in construction. It addresses:

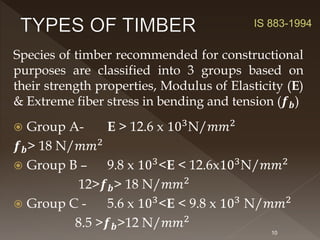

- Classification of timber based on strength properties and durability. The strongest timbers are classified as Group A.

- Key properties of timber including its anisotropic nature, moisture sensitivity, and variability between species. Seasoning and preservative treatment are important.

- Design considerations for flexural members including permissible stresses, shear design, bearing length factors, and deflection limits. Form factors must be applied based on member shape.

- Additional engineered wood products used in construction including glued laminated timber, cross-laminated timber, and plywood.

![ Timber is viable to seasonal cracks and

warping

Factor of safety depends on the exposure

conditions (inside, outside & wet) [Table 1]

Well seasoned timber are less liable to

volume changes

Green timber is weak

There is a risk of biological degradation,

when exposed to high moisture

conditions. [Table 2]

Defects in wood include knots, cracks,

wane, shake, dry rot, attack from termites,

white ants, wood borers etc.

5](https://image.slidesharecdn.com/011timber-230216171939-ac534927/85/011-TIMBER-pptx-5-320.jpg)

![24

Cl 7.5.5 Minimum Width > 50mm OR

1/50 of span

Cl 7.5.6 Depth < 3 times width

If Cl 7.5.5 & 7.5.6 cannot be satisfied, lateral stiffening should

be provided to resist bending or buckling

Cl 7.5.7 Shear

Cl 7.5.7.1 Maximum horizontal shear H

When load moves from support towards center &

load is at a distance of 3 to 4 times depth of beam

from support

Cl 7.5.7.2 Vertical end reaction or Shear at a section V

For concentrated & uniformly distributed loads

Cl 7.5.7.3 Deductions in load & Table 6 [Reduction

factors for concentrated loads]

IS 883

Greater](https://image.slidesharecdn.com/011timber-230216171939-ac534927/85/011-TIMBER-pptx-24-320.jpg)