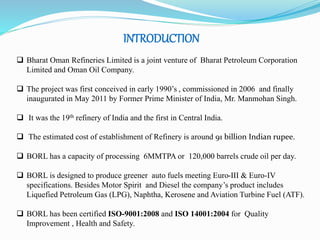

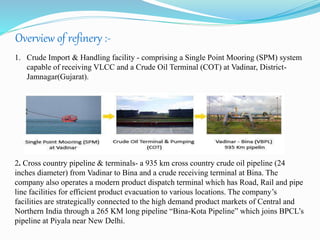

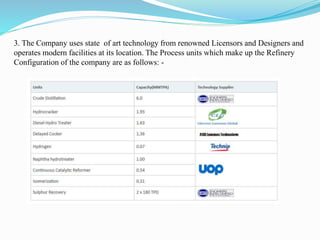

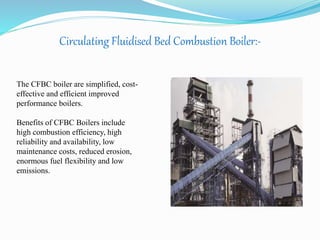

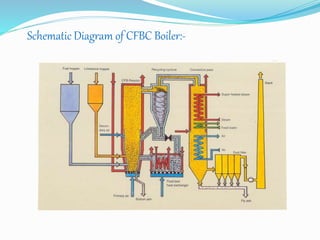

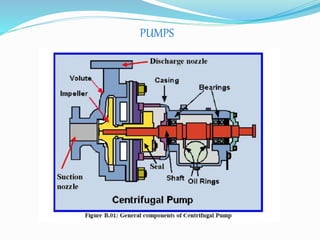

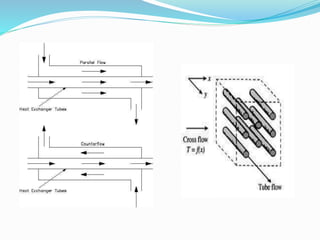

The summer internship presentation by Abhishek Jain focuses on mechanical machinery at Bharat Oman Refineries Limited (BORL), a joint venture that produces various automotive fuels. The refinery, inaugurated in 2011, has a processing capacity of 6 million metric tons per annum and employs advanced mechanical systems including boilers, pumps, compressors, valves, and heat exchangers. Additionally, the presentation details the technology used and the operational efficiencies achieved through innovative machinery and processes.