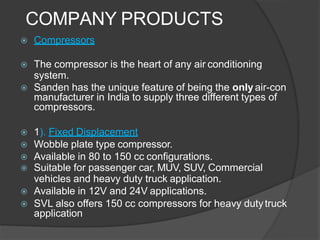

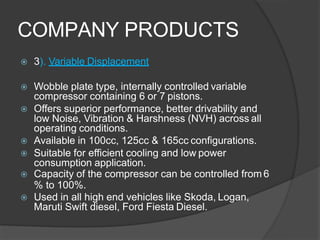

Pranav Vikas (India) Pvt. Ltd. is a heat exchanger manufacturer established in 1982 in Faridabad, India. Over the past 30 years, it has become one of the largest heat exchanger manufacturers in India with a strong R&D team and facilities for design and manufacturing. The company aims to be a world-leading heat exchanger manufacturer and benchmark in technology, design, manufacturing, and quality. Pranav Vikas produces aluminum heat exchangers for various applications and has received ISO and quality certifications. It also operates in other industries such as automotive air conditioning.