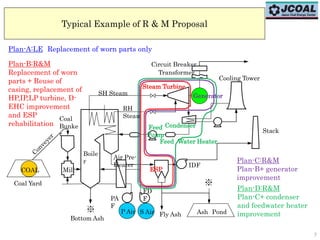

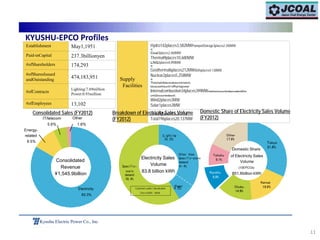

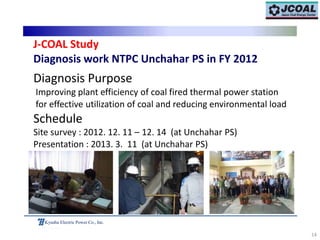

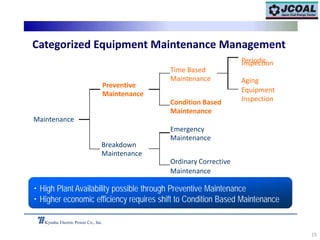

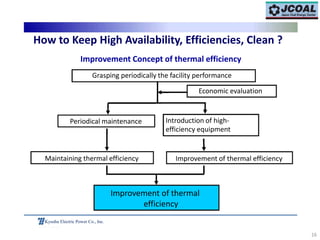

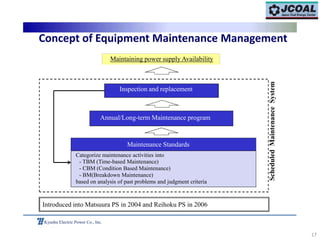

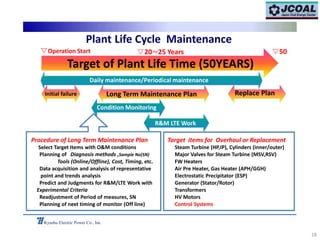

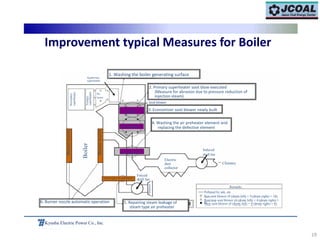

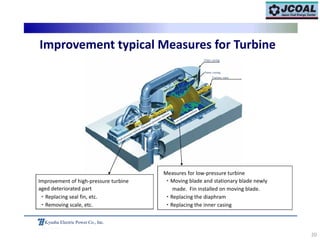

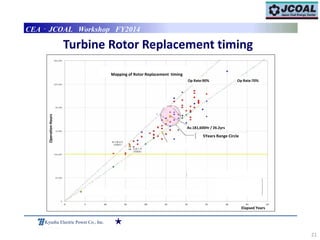

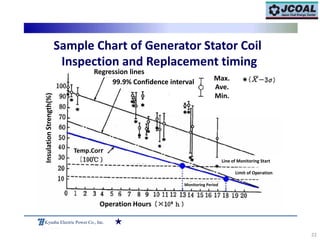

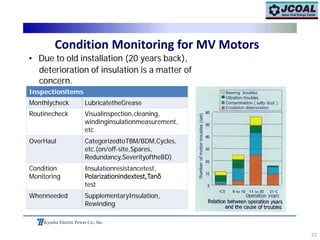

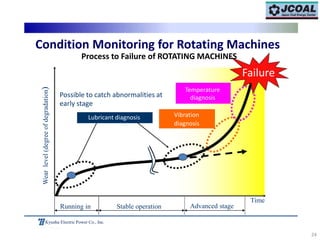

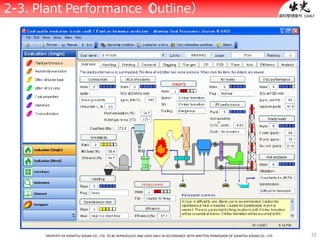

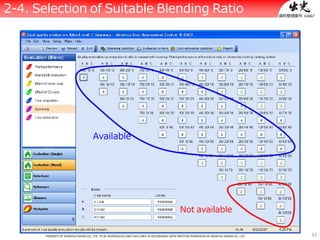

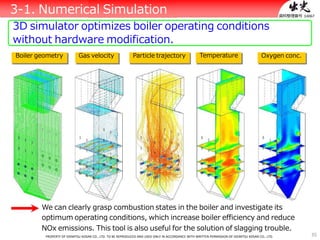

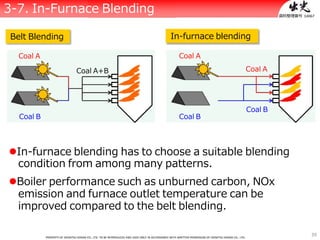

The document discusses operations and maintenance (O&M) practices at thermal power stations to improve efficiency. It provides examples from Kyushu Electric Power Co., which has implemented preventative and condition-based maintenance programs. Key measures taken by Kyushu include periodic inspections and replacements, improving boiler components like soot blowers and burners, and rehabilitating turbines by replacing aged parts to maintain efficiency over the plant lifetime.

![41

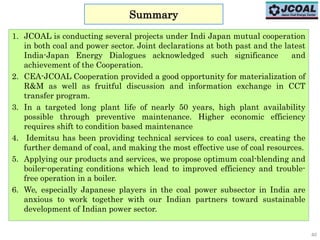

We look forward to working with you

Website:

http://www.jcoal.or.jp/index-en.html

Contacts:

Mr. K. Murakami (kzmurakami@jcoal.or.jp)

[Contact]

Engineering Group

International Business Division

Kyushu Electric Power Co. Inc.

2-1-82 Watanabe-dori, Chuo-ku, Fukuoka 810-8720 Japan

TEL: +81(92)726-1741 FAX: +81(92)716-4428

http://www.kyuden.co.jp/

Kyushu Electric Power Co., Inc.

Coal & Environment Research Laboratory

Coal Business Department

Idemitsu Kosan Co., Ltd.

Kyushu Electric Power Co., Inc.](https://image.slidesharecdn.com/measuresandequipment-160122084056/85/Measures-and-equipment-41-320.jpg)