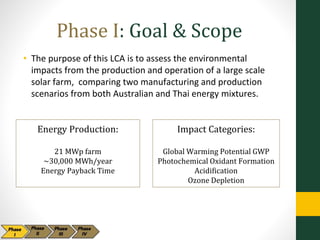

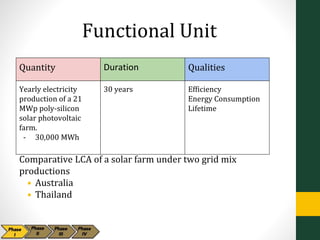

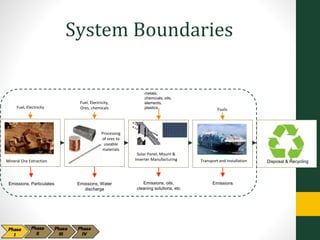

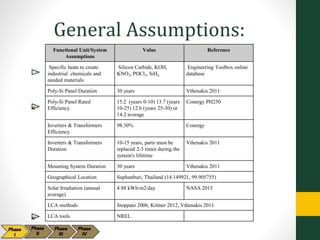

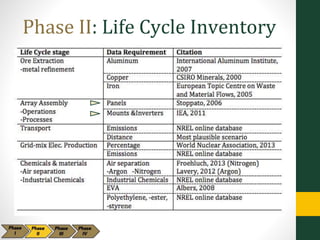

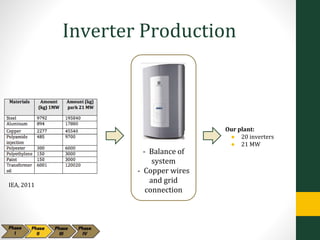

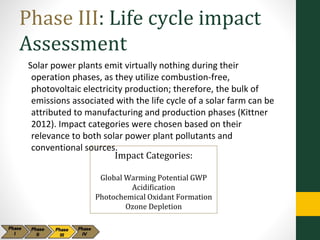

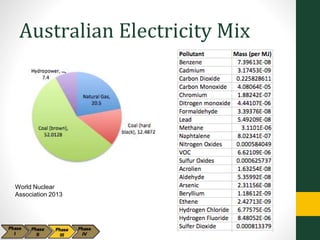

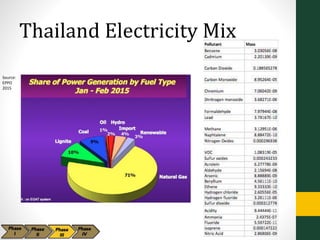

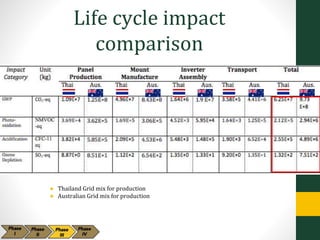

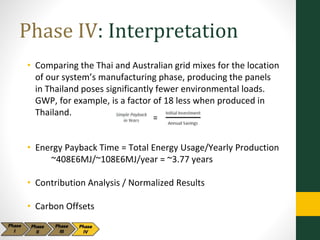

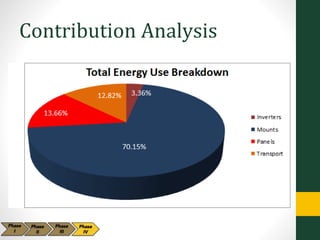

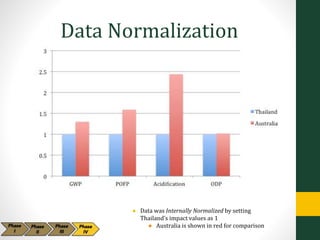

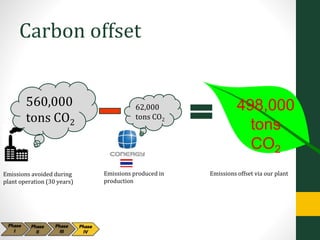

This document summarizes a life cycle assessment of a 21 MW solar photovoltaic farm in Suphanburi, Thailand. It finds that producing the solar panels in Thailand results in significantly lower environmental impacts than producing them in Australia due to differences in the countries' electricity grid mixes. Specifically, the study shows that greenhouse gas emissions are 18 times lower when produced in Thailand. It also determines that the manufacturing/production phase contributes most emissions over the solar farm's lifetime and that the system will offset 498,000 tons of carbon dioxide emissions over 30 years of operation.