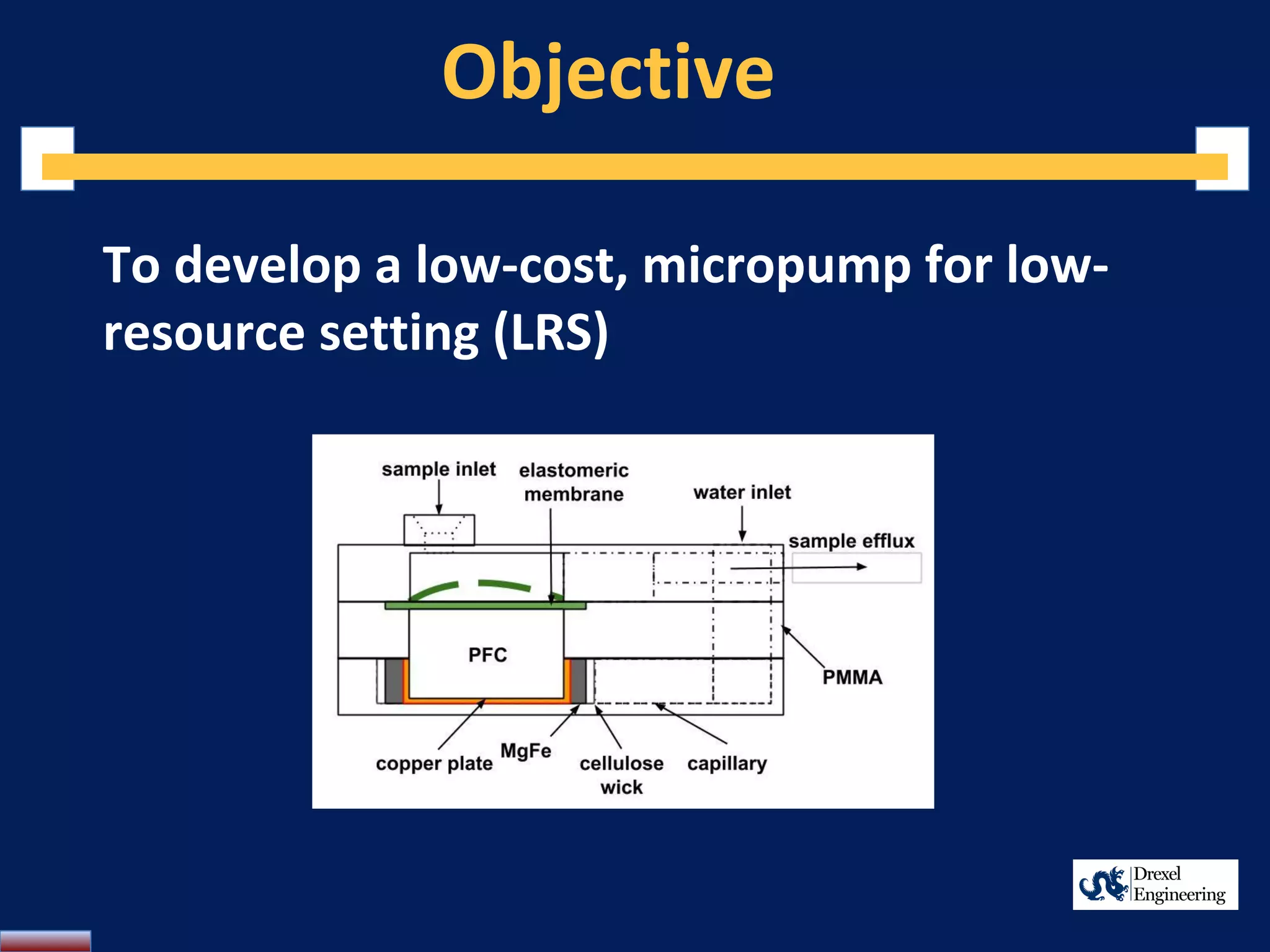

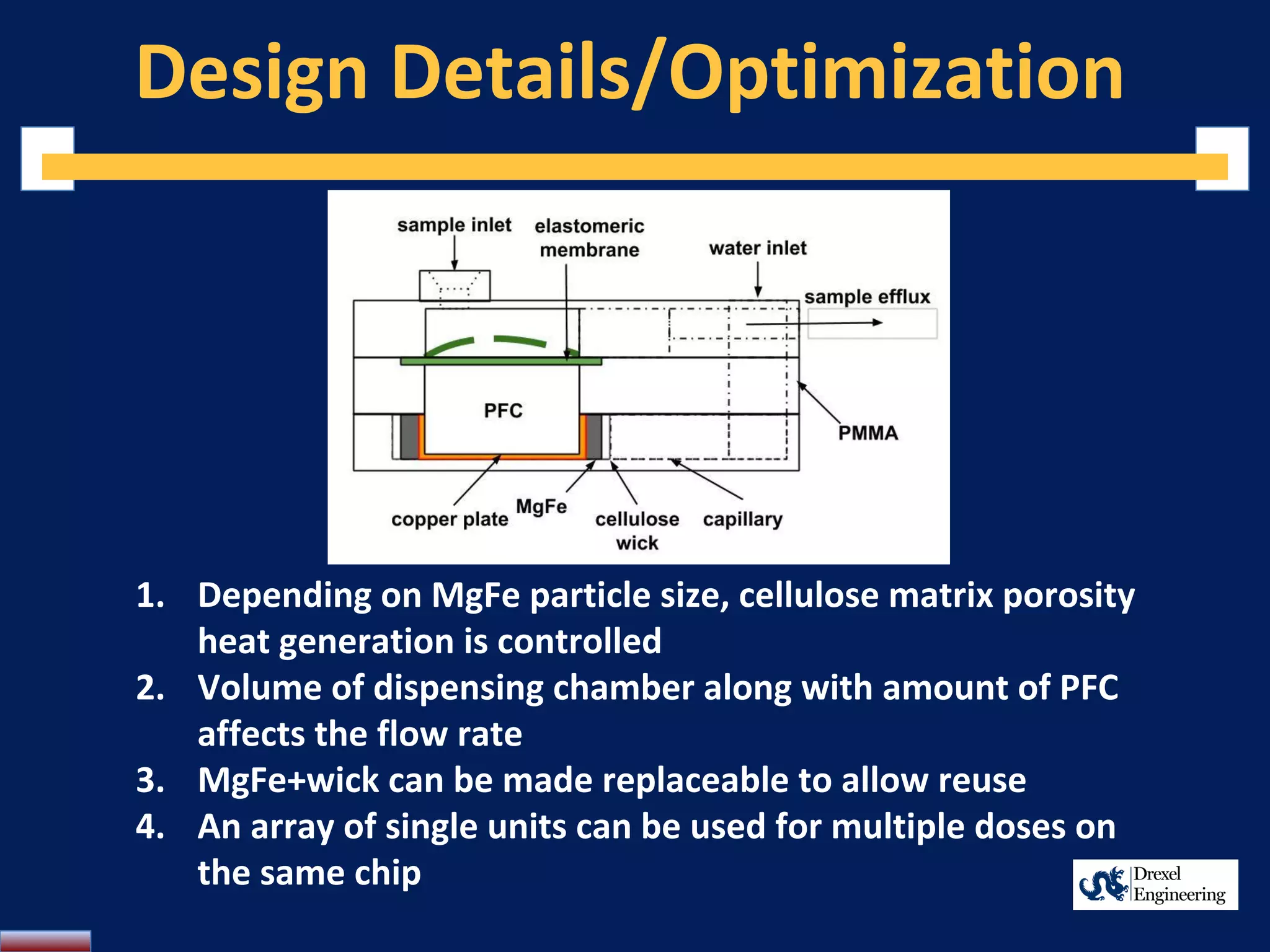

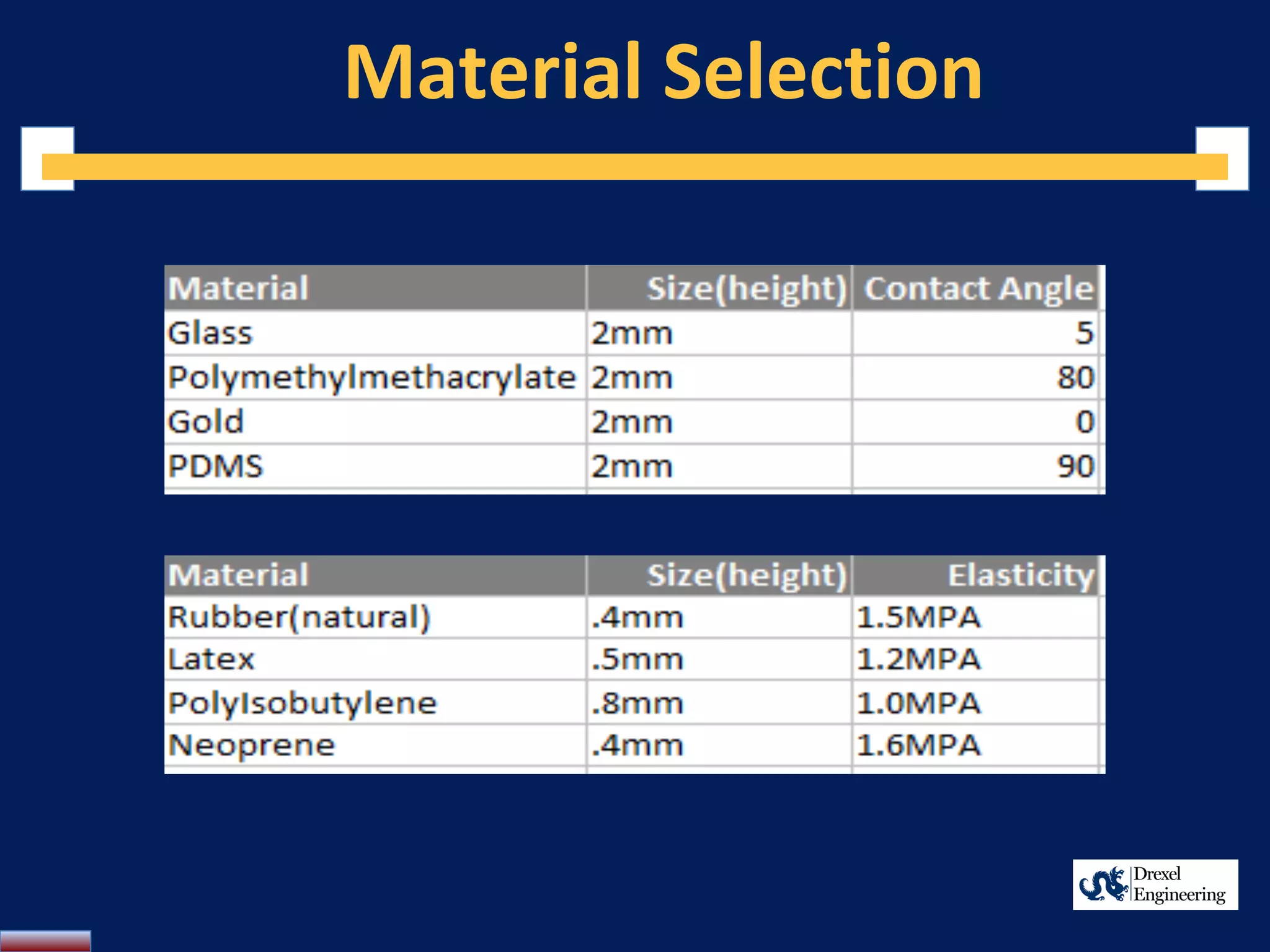

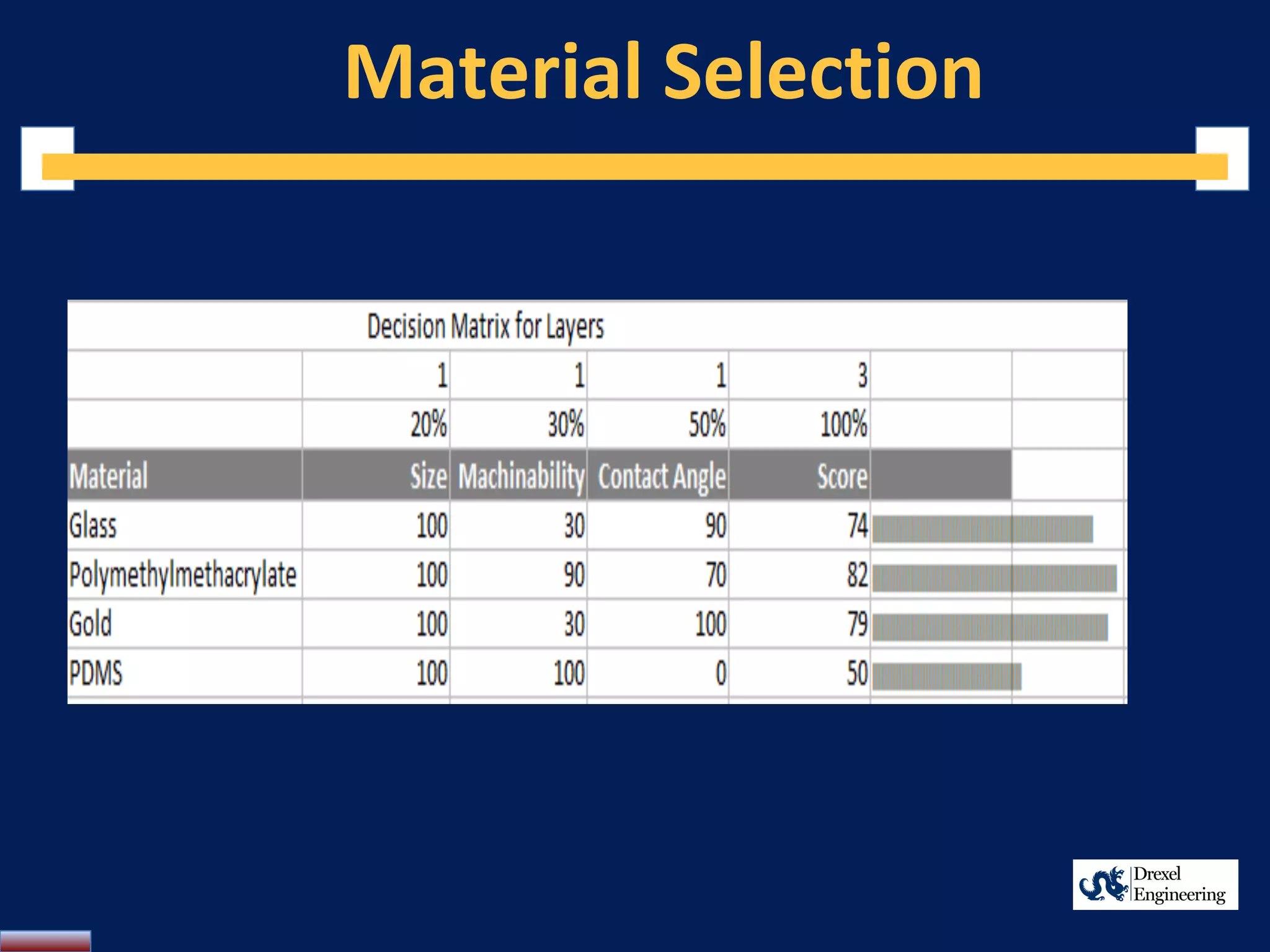

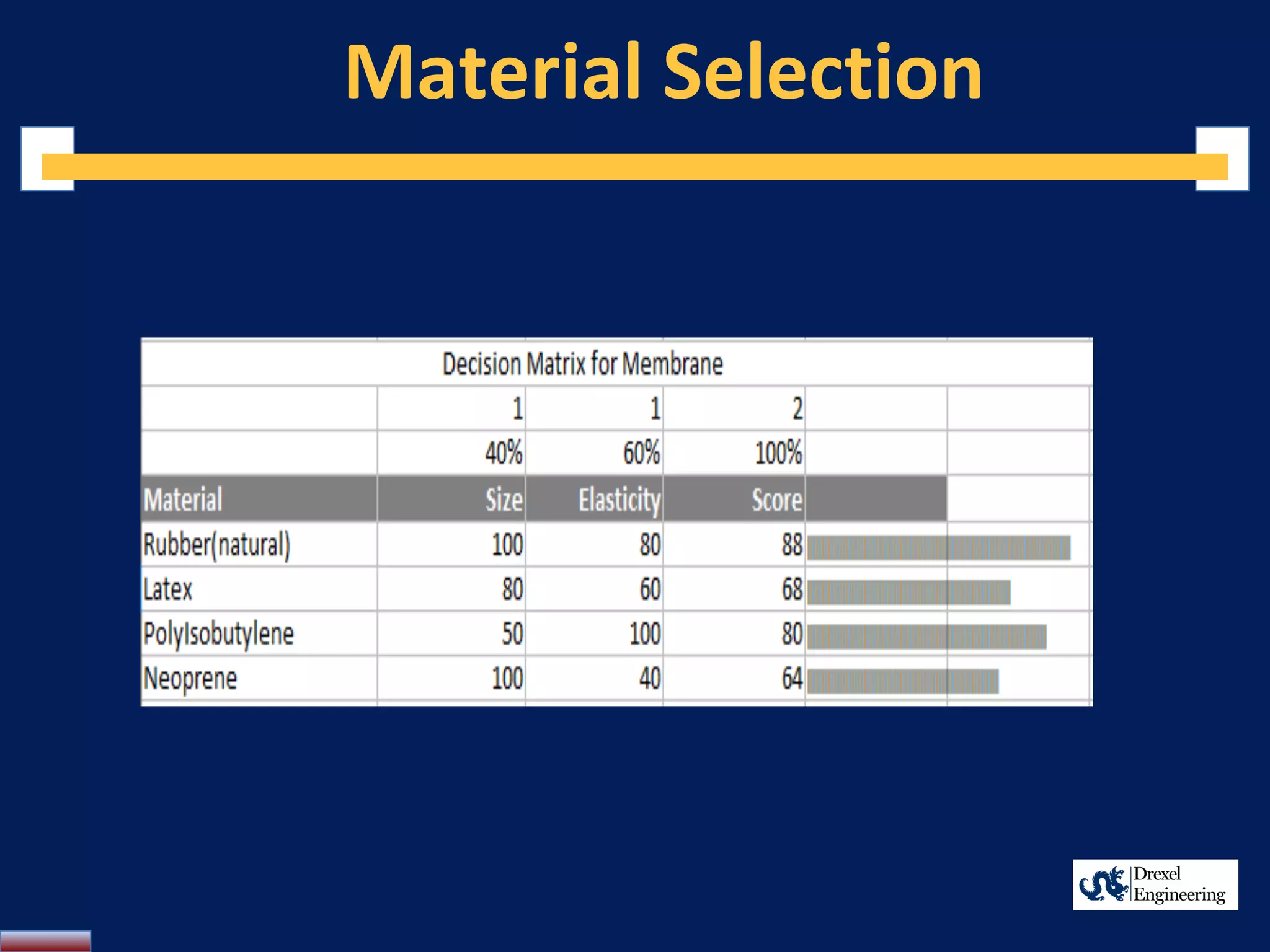

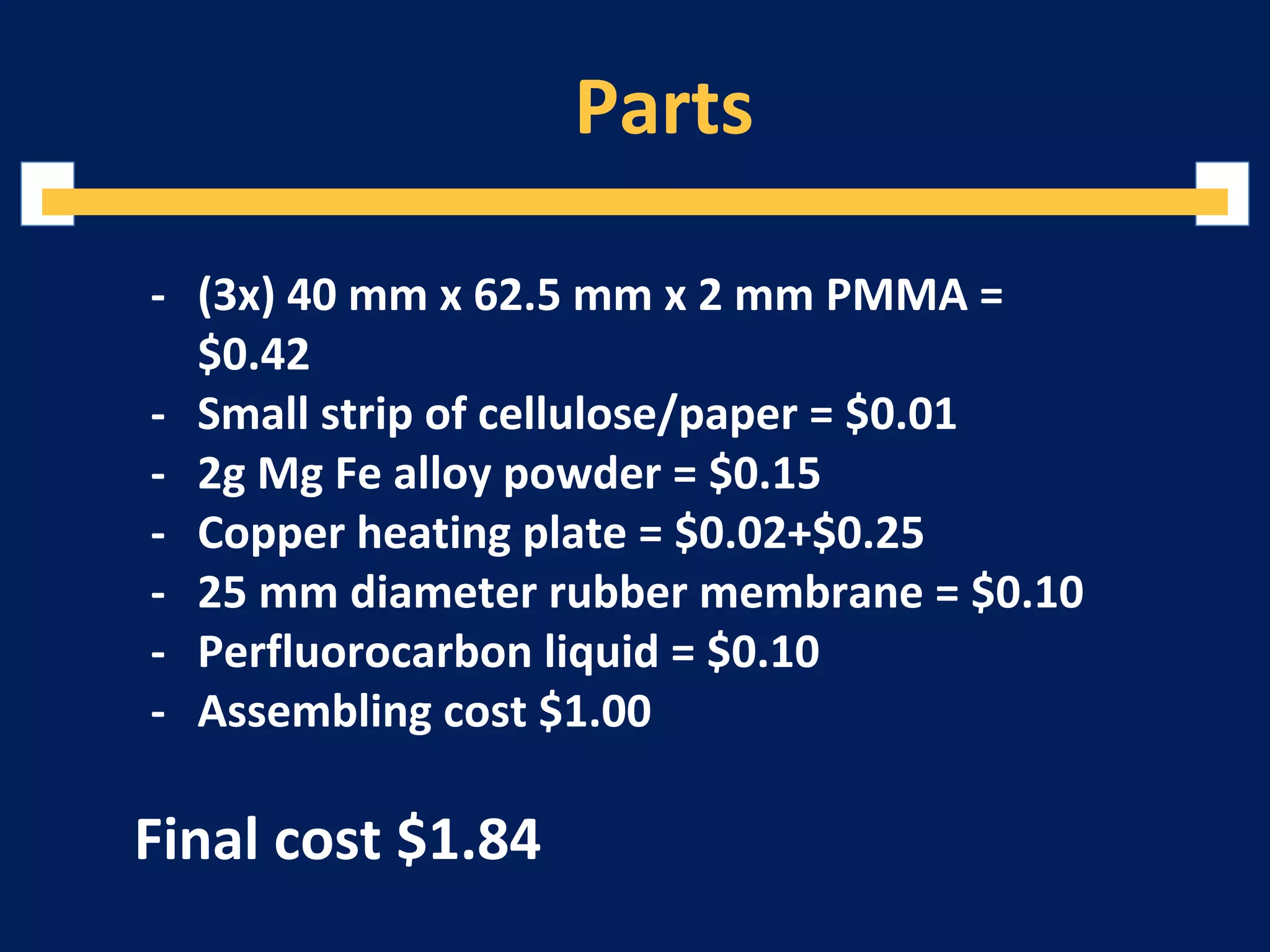

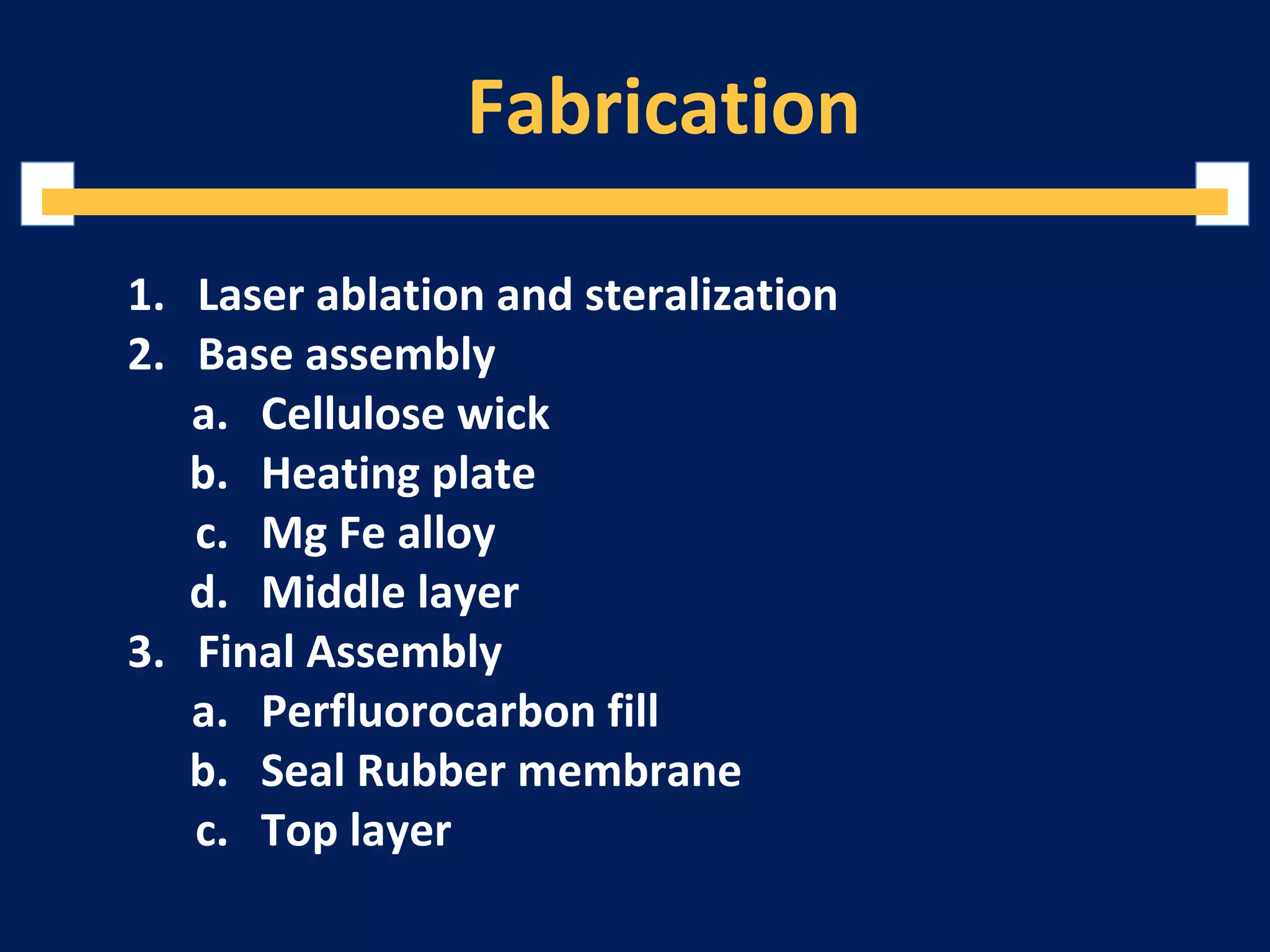

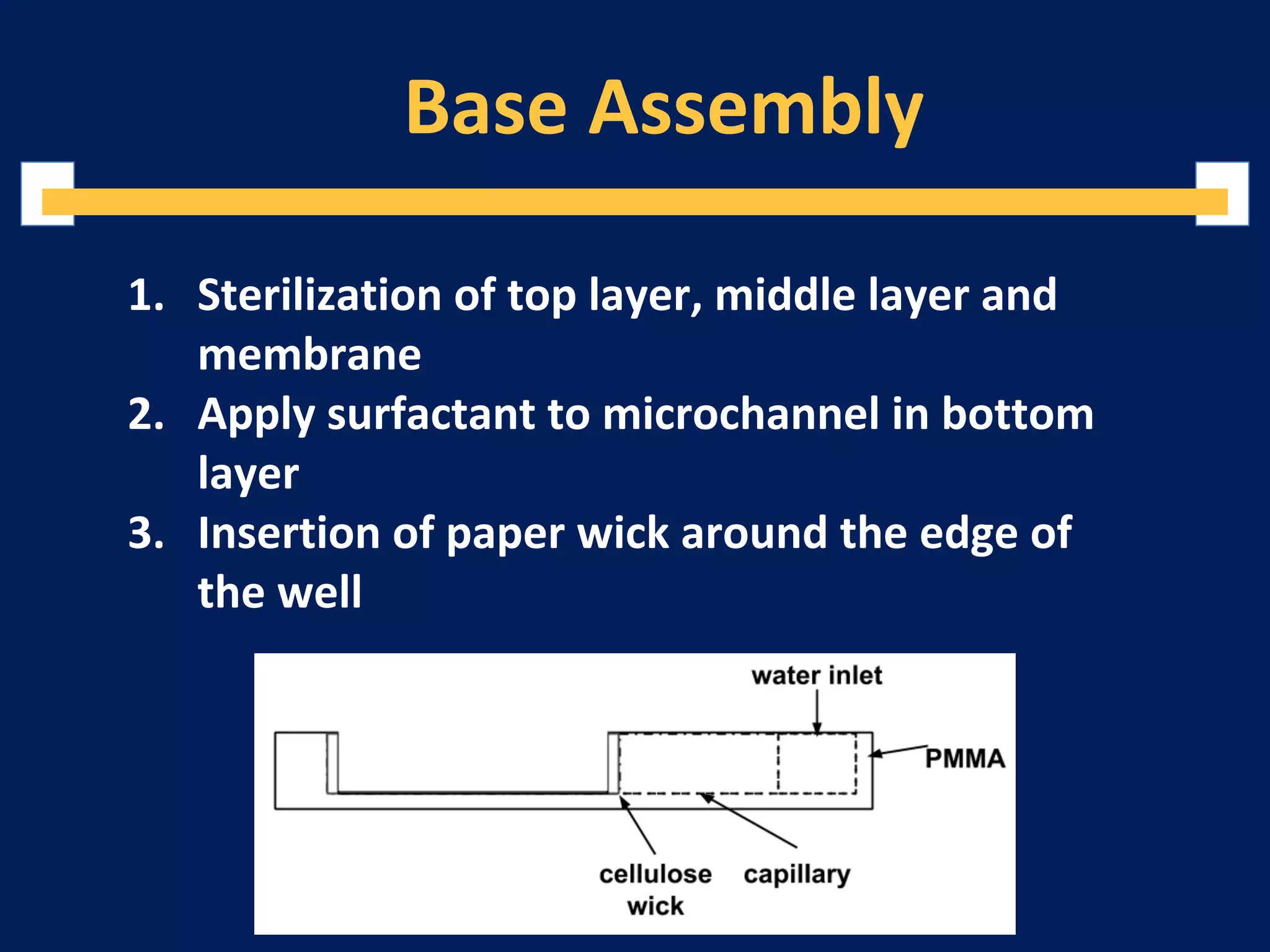

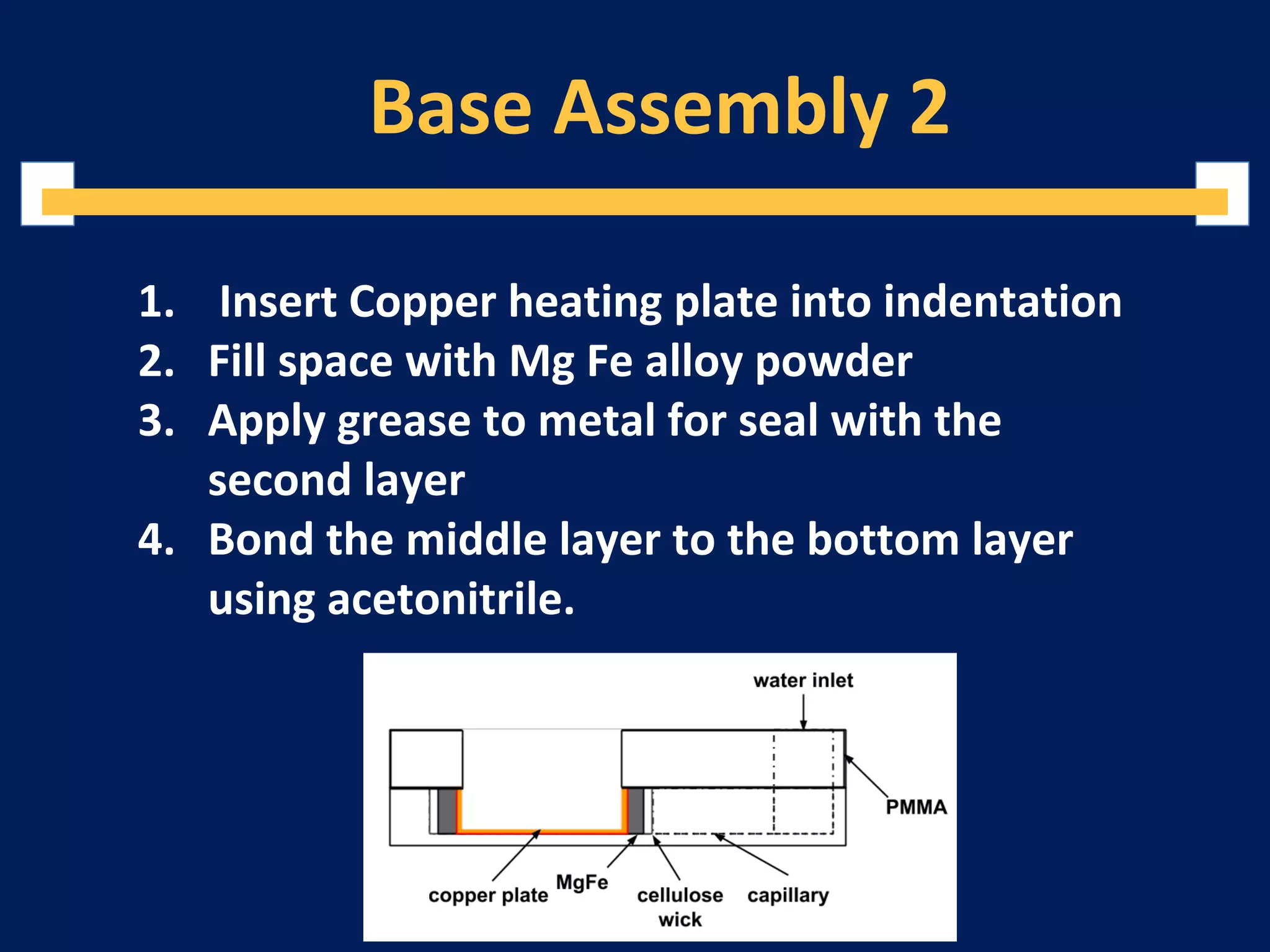

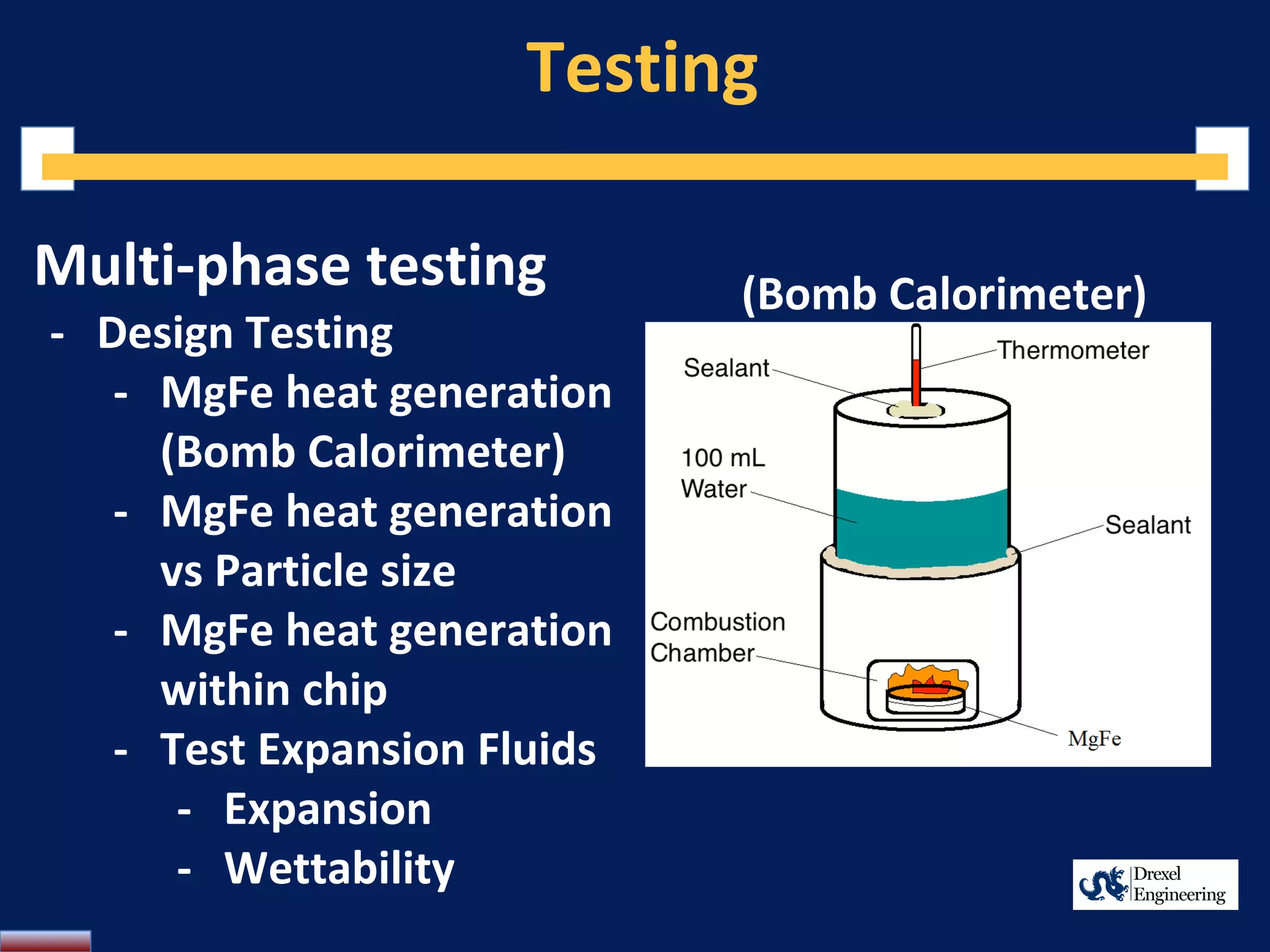

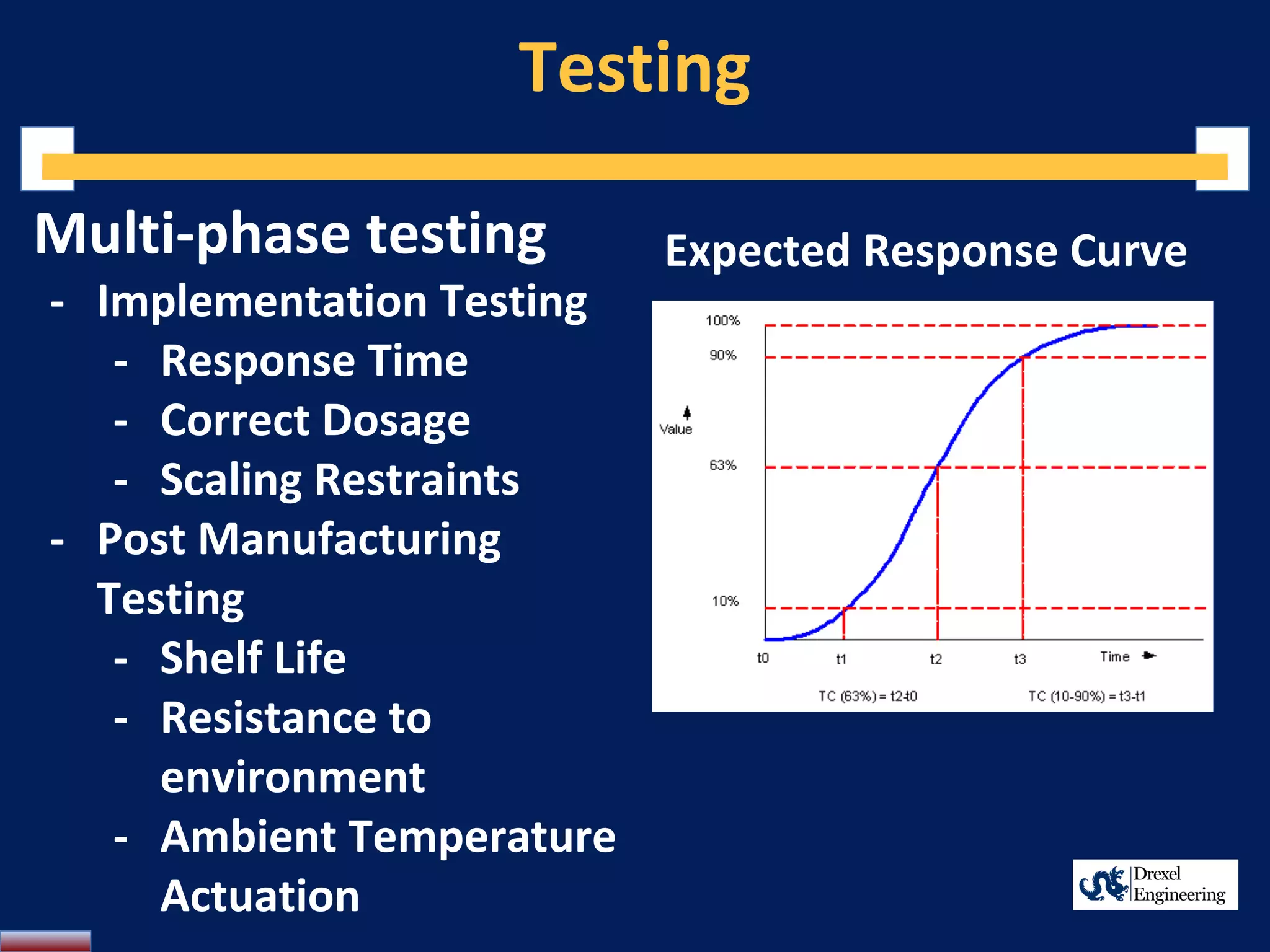

This document outlines the design and development of a low-cost, electricity-free thermopneumatic micropump aimed at low-resource settings for point-of-care diagnostic applications. The pump operates by generating heat through the reaction of magnesium-iron alloy with saline, which pressurizes a membrane to dispense fluid. Detailed sections cover design optimization, material selection, fabrication processes, and testing methods to ensure functionality and reliability in field conditions.

![Literature Review

A typical MEMS thermopneumatic

micropump by Jeong and Yang (2000)

[1]

A peristaltic PDMS thermopneumatic

micropump by Jeong et al (2005) [2]](https://image.slidesharecdn.com/3kgrhn3isvqtcdyodzqk-signature-755dc48a7d401d2cf8f2a46c5bb7a488da74370747eab3089ac225a666571ca3-poli-150406144040-conversion-gate01/75/Electricity-free-Thermopneumatic-Single-Dose-Micropump-for-Low-Resource-Setting-Applications-3-2048.jpg)

![Literature Review

A thermopneumatic dispensing

micropump by Cooney et al

(2004) [3]

A thermopneumatic micropump

using surface tensions by Jun et

al (2007) [4]](https://image.slidesharecdn.com/3kgrhn3isvqtcdyodzqk-signature-755dc48a7d401d2cf8f2a46c5bb7a488da74370747eab3089ac225a666571ca3-poli-150406144040-conversion-gate01/75/Electricity-free-Thermopneumatic-Single-Dose-Micropump-for-Low-Resource-Setting-Applications-4-2048.jpg)

![Material Selection [3]](https://image.slidesharecdn.com/3kgrhn3isvqtcdyodzqk-signature-755dc48a7d401d2cf8f2a46c5bb7a488da74370747eab3089ac225a666571ca3-poli-150406144040-conversion-gate01/75/Electricity-free-Thermopneumatic-Single-Dose-Micropump-for-Low-Resource-Setting-Applications-9-2048.jpg)

![References

[1] Jeong, Ok Chan, and Sang Sik Yang. "Fabrication and Test of a Thermopneumatic Micropump with a

Corrugated p+ Diaphragm." Sensors & Actuators: A.Physical 83.1 (2000): 249-55.

[2] Jeong, Ok Chan, Sin Wook Park, and Sang Sik Yang. "Fabrication and Drive Test of a Peristaltic

Thermopnumatic PDMS Micropump." Journal of Mechanical Science and Technology 19.2 (2005): 649-54.

[3] Cooney, Christopher G., and Bruce C. Towe. "A Thermopneumatic Dispensing Micropump." Sensors &

Actuators: A.Physical 116.3 (2004): 519-24.

[4] Jun, Do Han, Woo Young Sim, and Sang Sik Yang. "A Novel Constant Delivery Thermopneumatic

Micropump using Surface Tensions." Sensors & Actuators: A.Physical 139.1 (2007): 210-5.

For more info on MgFe: http://en.wikipedia.org/wiki/Flameless_ration_heater](https://image.slidesharecdn.com/3kgrhn3isvqtcdyodzqk-signature-755dc48a7d401d2cf8f2a46c5bb7a488da74370747eab3089ac225a666571ca3-poli-150406144040-conversion-gate01/75/Electricity-free-Thermopneumatic-Single-Dose-Micropump-for-Low-Resource-Setting-Applications-24-2048.jpg)