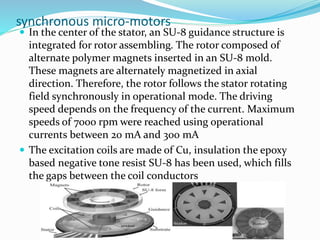

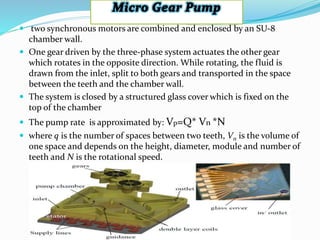

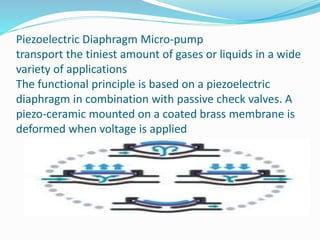

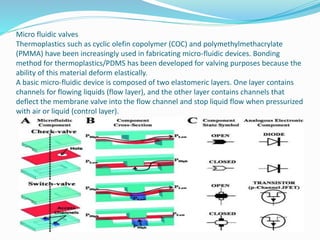

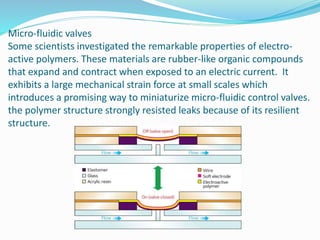

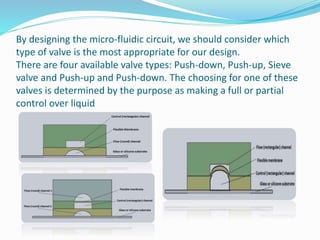

The document discusses various types of actuators used in microfluidic applications, including electrostatic, thermo-mechanical, magnetic, and piezoelectric actuators. It also describes different microfluidic devices that use these actuators, such as synchronous micromotors that use rotating magnetic fields, piezoelectric diaphragm pumps, and microfluidic valves based on deformable polymer membranes controlled by electric currents.