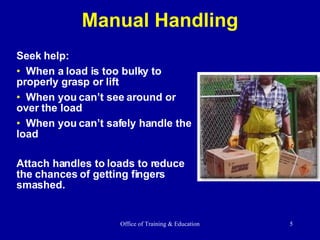

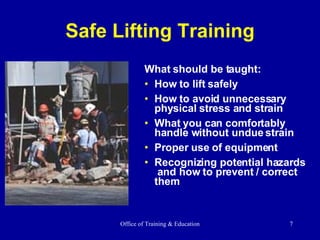

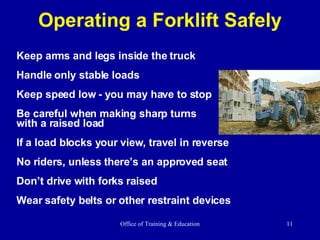

Handling and storing materials safely is important to prevent injuries. Materials should be lifted properly using leg muscles instead of the back to avoid strains. Equipment like forklifts, cranes and slings also present struck-by and crushed-by hazards and must be operated carefully. Sling capacities must be verified, inspections done for wear, and damaged gear removed from use. Good housekeeping including secured storage and debris removal helps create a safe work environment.