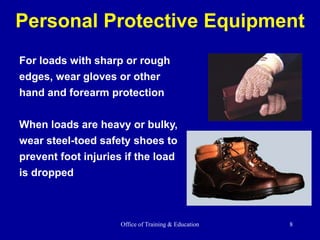

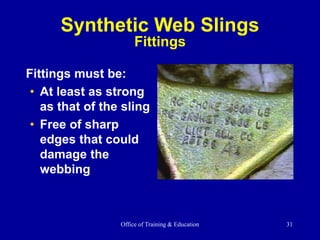

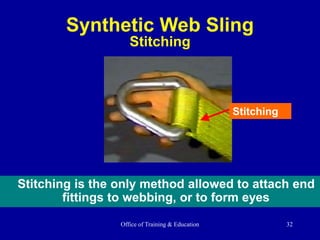

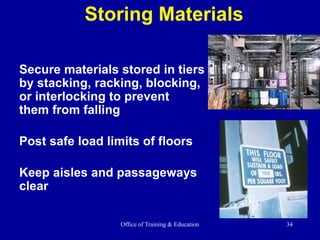

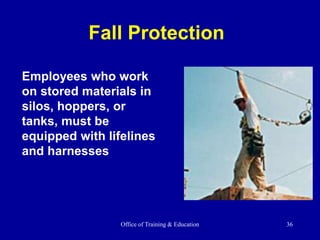

The document details safe practices for material handling, including manual lifting techniques and the proper use of equipment like forklifts and cranes to reduce the risk of injury. It emphasizes the importance of training employees on how to handle materials safely and the necessity of personal protective equipment. Additionally, it outlines guidelines for storing materials securely and disposing of waste to maintain a safe workplace environment.