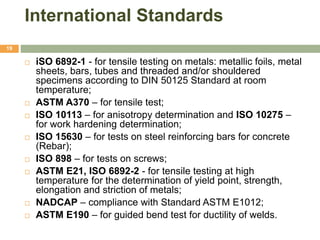

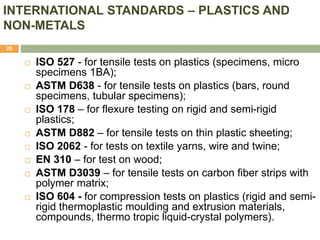

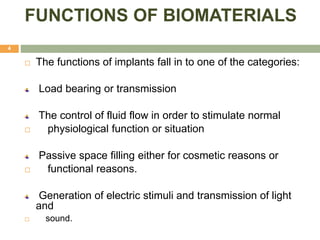

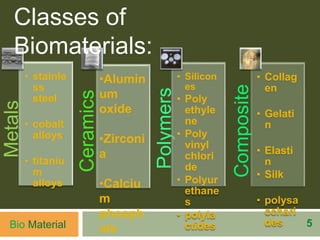

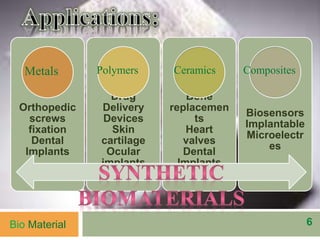

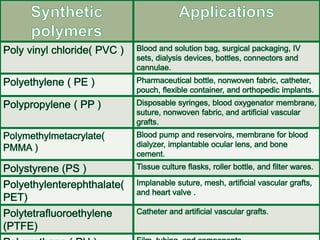

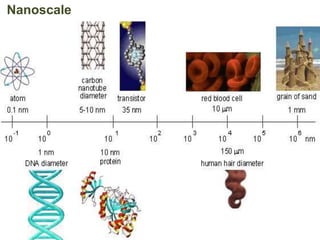

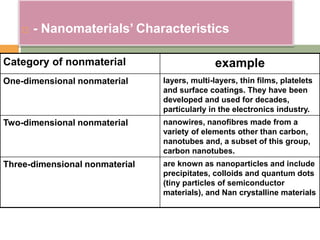

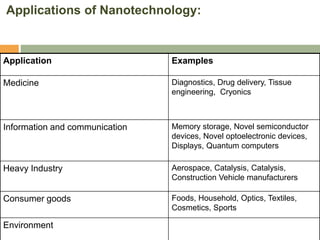

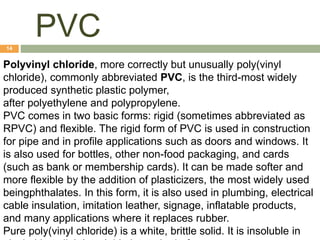

This document summarizes information about biomaterials and nanomaterials. It discusses how biomaterials are materials used as medical implants and devices to replace body parts, and lists some common classes of biomaterials like metals, ceramics, polymers and composites. It also provides an introduction to nanomaterials, describing them as materials with at least one dimension less than 100 nanometers. Examples of applications of nanotechnology in different fields like medicine, information technology and consumer goods are given. The document also discusses polyvinyl chloride (PVC), its properties and common uses. It covers non-destructive testing methods for materials and lists some international standards for mechanical testing of metals, plastics and other materials.

![15

Mechanical properties

Elongation at break 20–40%

Notch test 2–5 kJ/m

2

Glass Transition Temperature 82 °C

[3]

Melting point 100–260 °C

Effective heat of combustion 17.95 MJ/kg

Specific heat (c) 0.9 kJ/(kg·K)

Water absorption (ASTM) 0.04–0.4

Dielectric Breakdown Voltage 40 MV/m

Chemical

formula](https://image.slidesharecdn.com/14ch42-150420064123-conversion-gate02/85/materials-presentation-15-320.jpg)