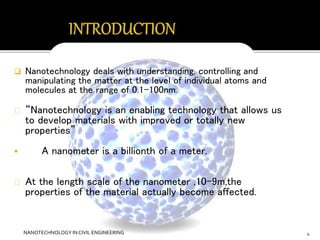

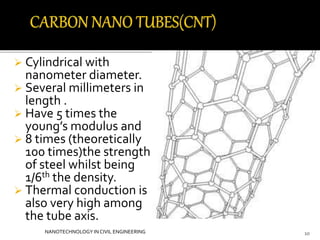

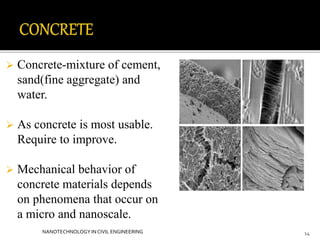

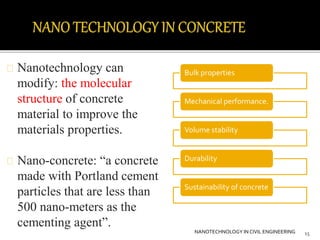

This document provides an introduction to nanotechnology and its applications in civil engineering. It discusses how nanotechnology can be used to improve properties of concrete, steel, glass, and other building materials. Specifically, it describes how nano-silica and carbon nanotubes added to concrete can increase its strength and durability. It also explains how copper nanoparticles in steel can enhance fatigue resistance and heat resistance. The document concludes by noting challenges of nanotechnology such as health risks to workers and high production costs.

![[1] Mann, S. (2006). “Nanotechnology and Construction,”

Nanoforum Report. www.nanoforum.org, May 30,

2008.

[2] Balaguru, P. N., “Nanotechnology and Concrete:

Background, Opportunities and Challenges.” Proceedings

of the International Conference – Application of Technology

in Concrete Design, Scotland, UK, p.113-122,

2005.

[3] ARI News (2005). “Nanotechnology in Construction – One

of the Top Ten Answers to World’s Biggest

Problems.”

www.aggregateresearch.com/article.asp?id=6279, June 1,

2007.

39](https://image.slidesharecdn.com/jerrypaulvarghese-140902093952-phpapp01/85/nano-technology-in-civil-engineering-39-320.jpg)