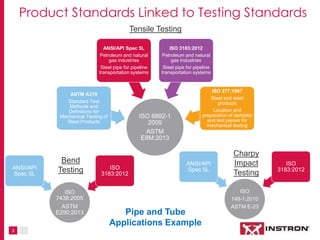

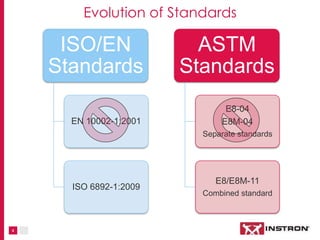

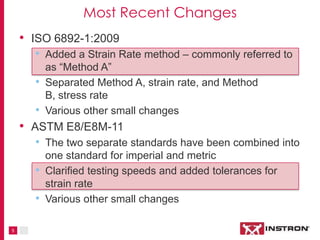

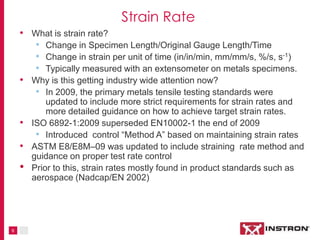

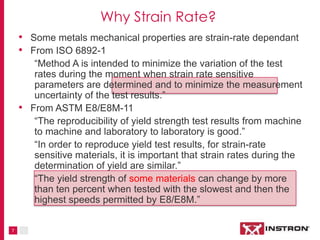

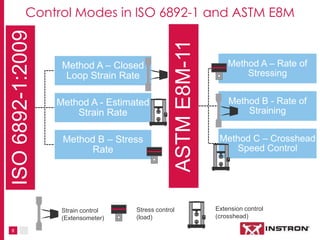

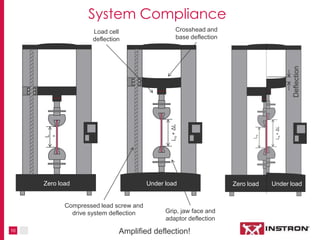

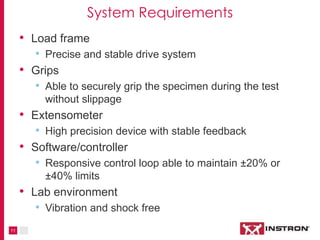

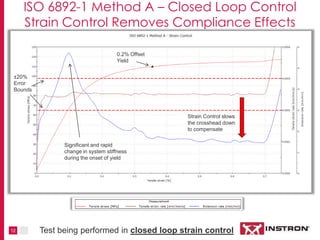

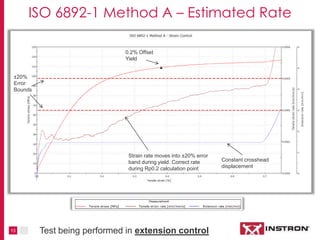

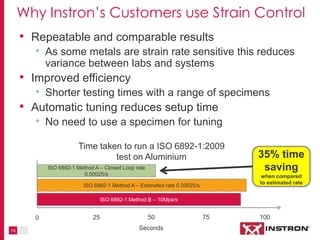

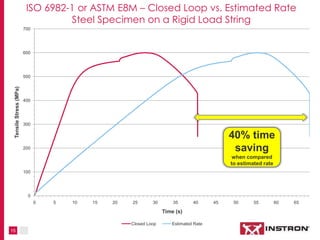

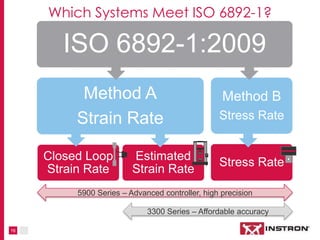

The document discusses recent updates to metals testing standards, focusing on changes to strain rate methods in ISO 6892-1:2009 and ASTM E8/E8M-11 standards. It highlights the importance of controlled strain rates in testing metals due to their strain-rate dependent mechanical properties, and provides insights into the compliance requirements for these standards. The document also emphasizes the benefits of using advanced testing systems that can improve efficiency and repeatability in results.