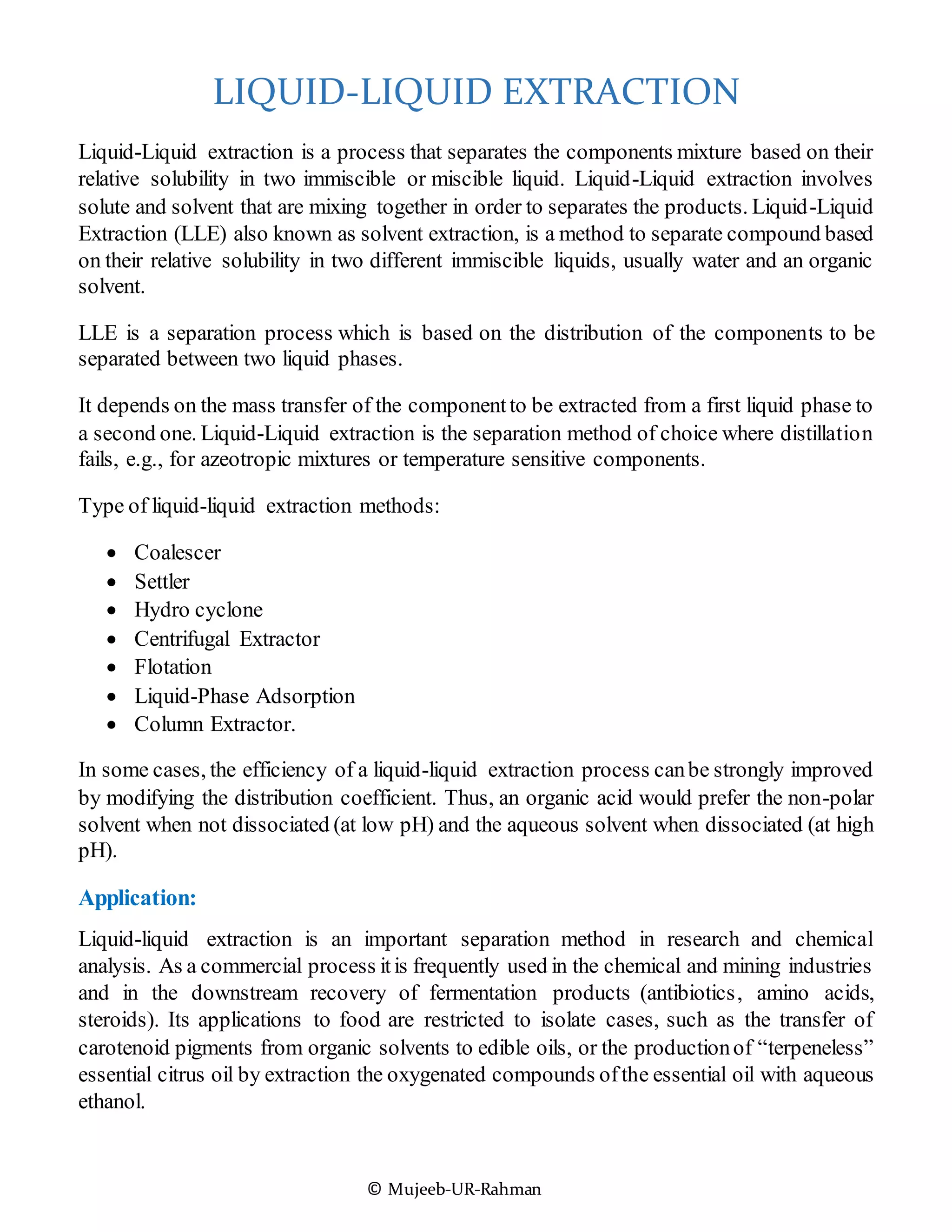

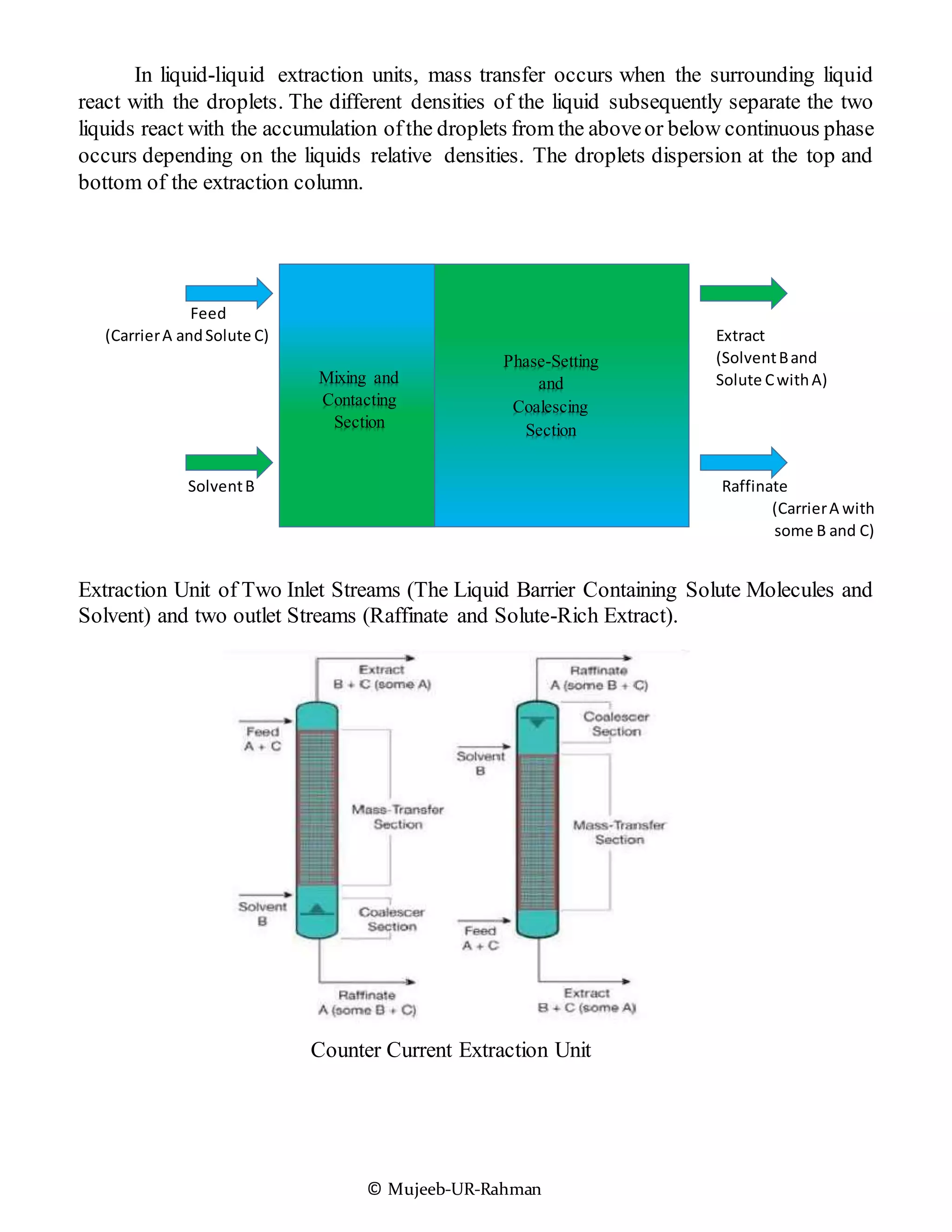

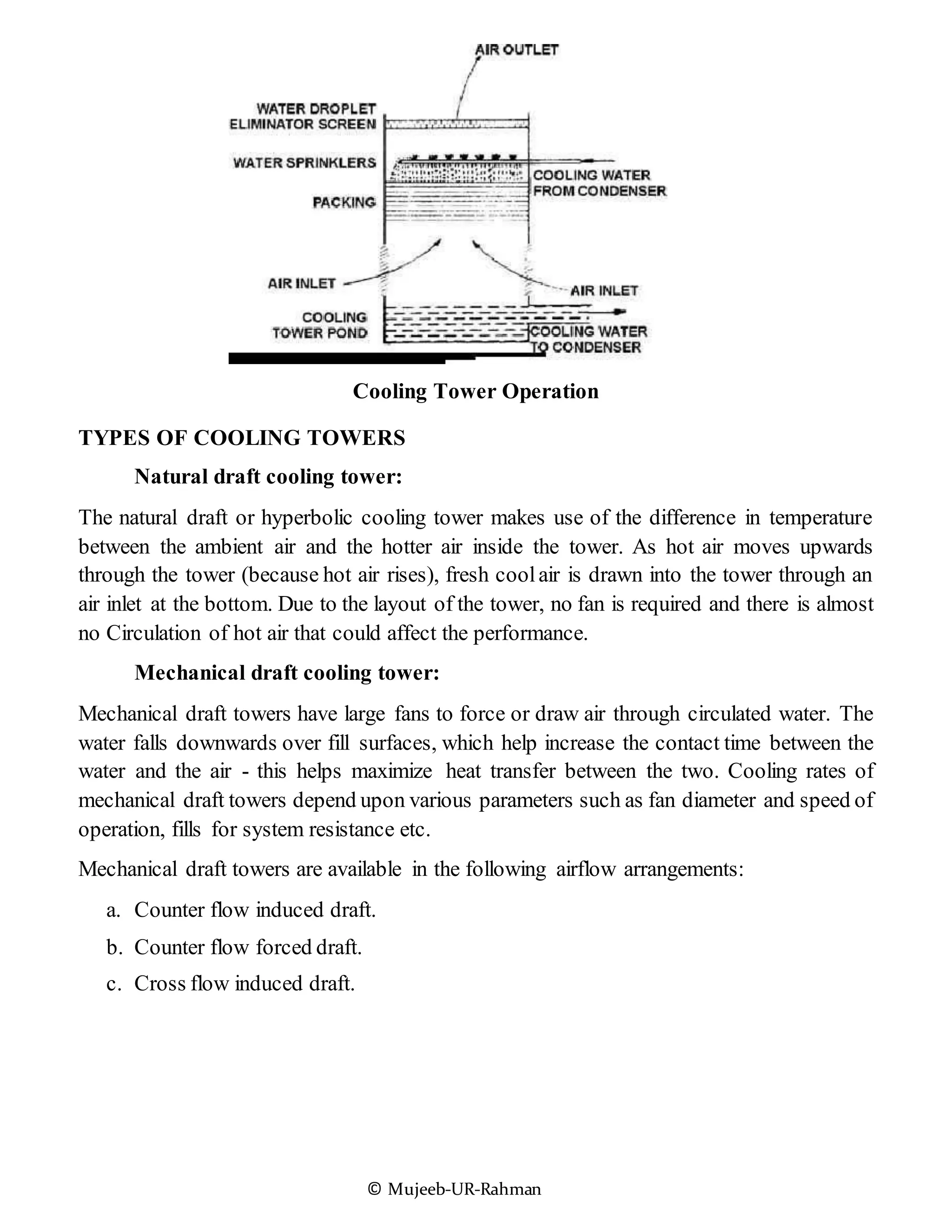

The document provides an overview of various mass transfer processes including liquid-liquid extraction, solid-liquid extraction, rising film evaporation, cooling towers, ion exchange, absorption, adsorption, drying, distillation, and crystallization. For each process, a definition and basic principles are given along with common applications. Diagrams are also included to illustrate some of the key process equipment and flow schemes.