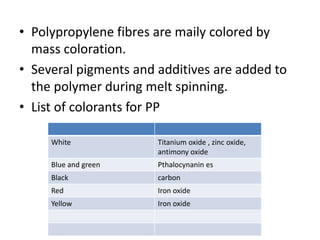

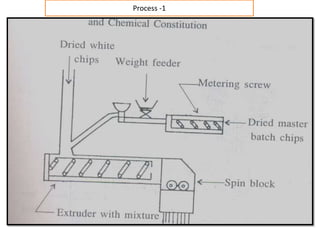

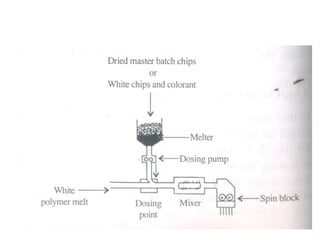

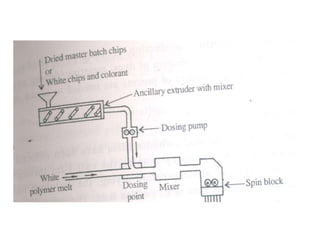

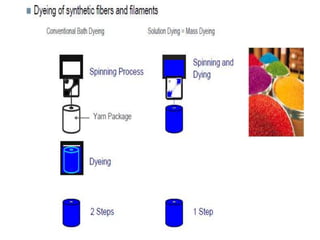

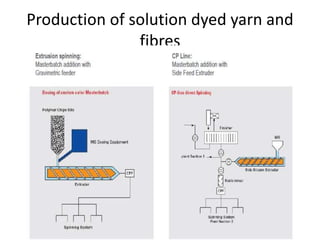

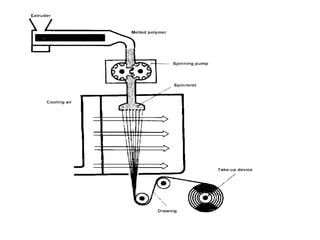

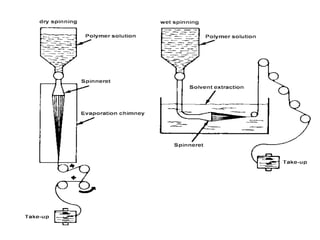

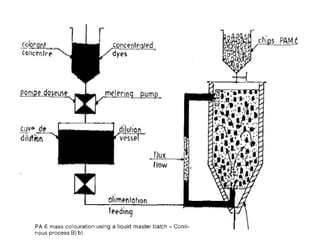

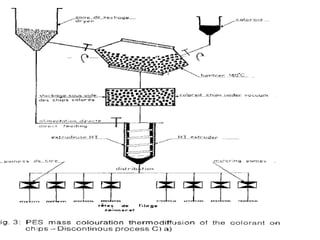

Mass coloration, also known as solution dyeing or spun dyeing, involves adding pigments or insoluble dyes to the spinning solution or polymer melt before extrusion through a spinneret. This embeds the color within the fiber, resulting in fibers with excellent colorfastness to light, washing, rubbing, and other stresses. Mass coloration can be applied to both regenerated and synthetic fibers and is more economical and less wasteful than conventional dyeing processes. The most common mass coloration methods are addition during polymerization, chips coating, master batch addition, and injection into the extruder.