Marine update resume

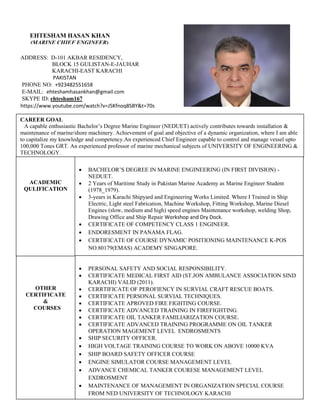

- 1. MM EHTESHAM HASAN KHAN (MARINE CHIEF ENGINEER) ADDRESS: D-101 AKBAR RESIDENCY, BLOCK 15 GULISTAN-E-JAUHAR KARACHI-EAST KARACHI PAKISTAN PHONE NO: +923482551658 E-MAIL: ehteshamhasankhan@gmail.com SKYPE ID: ehtesham167 https://www.youtube.com/watch?v=JSKfnoq8SBY&t=70s CAREER GOAL A capable enthusiastic Bachelor’s Degree Marine Engineer (NEDUET) actively contributes towards installation & maintenance of marine/shore machinery. Achievement of goal and objective of a dynamic organization, where I am able to capitalize my knowledge and competency.An experienced Chief Engineer capable to control and manage vessel upto 100,000 Tones GRT. An experienced professor of marine mechanical subjects of UNIVERSITY OF ENGINEERING & TECHNOLOGY. ACADEMIC QULIFICATION BACHELOR’S DEGREE IN MARINE ENGINEERING (IN FIRST DIVISION) - NEDUET. 2 Years of Maritime Study in Pakistan Marine Academy as Marine Engineer Student (1978_1979). 3-years in Karachi Shipyard and Engineering Works Limited. Where I Trained in Ship Electric, Light steel Fabrication, Machine Workshop, Fitting Workshop, Marine Diesel Engines (slow, medium and high) speed engines Maintenance workshop, welding Shop, Drawing Office and Ship Repair Workshop and Dry Dock. CERTIFICATE OF COMPETENCY CLASS 1 ENGINEER. ENDORESMENT IN PANAMA FLAG. CERTIFICATE OF COURSE DYNAMIC POSITIONING MAINTENANCE K-POS NO.80179(EMAS) ACADEMY SINGAPORE. PERSONAL SAFETY AND SOCIAL RESPONSIBILITY. CERTIFICATE MEDICAL FIRST AID (ST.JON AMBULANCE ASSOCIATION SIND KARACHI) VALID (2011). CERRTIFICATE OF PEROFIENCY IN SURVIAL CRAFT RESCUE BOATS. CERTIFICATE PERSONAL SURVIAL TECHNIQUES. CERTIFICATE APROVED FIRE FIGHTING COURSE. CERTIFICATE ADVANCED TRAINING IN FIREFIGHTING. CERTIFICATE OIL TANKER FAMILIARIZATION COURSE. CERTIFICATE ADVANCED TRAINING PROGRAMME ON OIL TANKER OPERATION MAGEMENT LEVEL ENDROSMENTS SHIP SECURITY OFFICER. HIGH VOLTAGE TRAINING COURSE TO WORK ON ABOVE 10000 KVA SHIP BOARD SAFETY OFFICER COURSE ENGINE SIMULATOR COURSE MANAGEMENT LEVEL ADVANCE CHEMICAL TANKER COURESE MANAGEMENT LEVEL EXDROSMENT MAINTENANCE OF MANAGEMENT IN ORGANIZATION SPECIAL COURSE FROM NED UNIVERSITY OF TECHNOLOGY KARACHI OTHER CERTIFICATE & COURSES

- 2. Extensive knowledge of Marine Designing & Engineering Life Cycle Coasting. Knowledge of Coastal & Environmental Engineering. Extensive knowledge of Marine Slow Speed Engine overhauling maintenance and rebuilding works. Hydraulic power unit, driving propeller, and electrical power motor driven vessel. CPP, Double mounted propeller, RTD, Azi-POD, Azi-Mouth method operation. Knowledge of Engineering Management & Engineering Economics. Able to handle marine propulsion problem on shore and off shore. Knowledge of all type of hydraulic machinery operation and maintenance. Knowledge of power plant operation, power generation, distribution, gridding, console control room monitoring power factor, steam and turbine generation of electricity. Knowledge of Bulk, Container, RORO, Crane, DP, Marine Cable and Anchor Handling vessels. Knowledge of Drill-Vessel and Oil / Gas Rig operation, Rig Shipment and Rig repair. SUMMARY OF QUALIFICATION OPERATING M.S OFFICE 2012 ON WINDOW-8 Cor- i7. COMPUTER AID MECHANICAL DESIGNING. COMPUTER AID MACHINERY OPERATION. MARINE DESIGNING & ENGINEERING COST ANALYSIS. SHIPNET PROGRAMMING- PIL/QATAR NAVIGATION/IRISL/ KOTC/NITC/ MEARSK LINE/AMOS-PROGRAMMING. COMPUTER SKILLS PROFESSIONAL EXPERIENCE DRY DOCKING SERVING PAKISTAN NATIONAL SHIPPING CORPORATION KARACHI FROM JUNE 1983-----2007. Performed Dry Dock repairs of M.V “HYDERABAD", M.V "SARGODHA", M.V "ISLAMABAD", M.V "MUREE", M.V "MALAKAND", M.V KHAIRPUR", M.V "MAKRAN" AND M.V "MULTAN". Two Dry Docks in Japan, Two in Korea, Two Dry Dock in China, and two in Vietnaman Worked with SABRO ENGINEER in A/C Plants, Refrigeration Plants, consist of complete overhauling of units replacement of parts, installation of new A/C plant and refrigeration system. Served with TSUJI-JAPAN & LIBRRE Cranes hydraulic systems, and all attached system with hydraulic system. Worked and assisted ABB service engineers(Osaka Japan) GEMANY, ABB,ABB ITALY AND ABB DUBAI dismantling overhauling of ABB VTR-501, VTR 601, VTR801 Turbocharger 2in numbers fitted in Main Engine. Dismantling propeller, propeller shaft, shaft seals (inner and outer) and intermediate shaft. Reassembled propeller shaft, shaft seals (new) and propeller Hydraulic tighten. During these jobs various readings recorded and tallied with marker book found within limitation. Experience Maintaining MAC GREGOR Cranes , relief valve adjustment, Rocking Tests Cards replacement. Experience Maintaining TSUJI CRANES/ LIBRRE CRANES . Replacements of pumps overhauling of pumps, zero adjustment, replacement of seals, replacement of hydraulic pistons, and Setting of hydraulic pressures. Rollers and Bearings replacement. Experience Maintenance of REVERSE OSMOSIS. Overhauling of multi-stage Pumps. Chemical Dosing, Replacement of Filters, Back Flashing and Membranes Stag Cleaning. Experience of Maintenance of all the PUMPS of any type and Make. Can Overhaul reciprocating, Scroll, Centrifugal, Multi combination vanes/scrolls & Multi-Pistons Pumps. SCREW AIR COMPRESSOR Complete overhauling screw replacement seal replacement, bearing replacement. FRAMO PUMP Complete overhauling, impeller replacement, wear rings replacement, seal replacement. These pumps are vital for chemical cargo discharge.

- 3. OTHER PROFESSIONAL EXPERIENCES. seal replacement. These pumps are vital for chemical cargo discharge. SCROLL PUMP complete overhauling. These pump use discharging oil / chemical. MAIN AIRCOMPRESSOR: Tanabe tandem type, Ham worthy two pistons two stages and polish air compressor. Complete cylinder head, cylinder block, connecting rod, piston & pistons ‘rings, bottom end bearings and all stages valves replacements. PURIFIER:-Well experience in maintenance of MitsubishiSJ-6000, SJ-4000, SJ-3000, and SJ-2000(Japanese Class), ALFA LAVAL , D-LAVAL and Westphalia (European Class).Complete dismantling of bowl parts & replacement. Vertical shaft dismantling bearings renewal and reassembling. Vertical shaft height adjustment according to Maker limitation. Horizontal shaft dismantling parts renewal bearings renewal. Pulley and Boss renewal, frictional pads renewal. All parts reassembling and electrical motor fitting. Water assembly parts dismantling parts cleaning/replacement and reassembling. HYDRAULIC STEERING GEAR: - Rams seal replacement, Hale Shaw pump overhauling (Plate or Piston type).Pumps tank and suction filters cleaning. Solenoids valves fault detection & rectification during passage by changing over safely without ship stoppage. Single Ram operation Double Rams Operation/ Change over Ram during Sea Voyage without any stoppage. AUTO PILOT PUMP . Hydraulic Pump overhauling / maintenance tank oil renewal, suction filer cleaning gauge replacements. Hydraulic valves replacement RUDDER CARRIER BEARING: - Greasing, tank level maintaining, even rudder gland replacement without dry-docking. Tank inspection during dry-docking. Monitoring rudder gland cooling rectifying leakage of sea water during running. PROPELLERS:- Dismantling of Propeller hydraulically [Hyd. Pressure 540kg/cm2___ 680 kg/cm2], inspecting the incline surface. Polishing the incline surface. Filling Tallow in the cone. Mounting the Propeller Cone by hydraulic pressure. Tighten Propeller nut & locking the nut. Assembling the Cone filling Tallow. Measuring wear down allowance by Poker Gauge, outer Seal and Inner Seal. Replacing propeller fan from controllable pitch propeller, and reassembling new propeller fan. Assembling propeller without rudder Propeller encircle cage, propeller with movable end. HYDRAULIC DECK MACHINERY: - Experience and confidence in maintenance of FUKOSHIMA (Japan) hydraulic deck machinery. Can dismantle hydraulic pump, vanes replacement, seal/o-rings replacement and coupling chine replacement. Maintaining gear oil in reduction gearing, greasing bearing& cleaning magnetic filter. Can dismantle hoist, luffing and slewing winch motor with vanes replacement overhauled remote blocks(luffing, hoisting and slewing)with parts renewal. Adjustment of Relief valve / parts renewal of relief valve. Speed adjustment. Installation of Luffing, Slewing and Hoisting motor complete assembly. Including wrapping of wire ropes and wire guard fitting. MOORING / CAPSTAIN/ HYD. RAMP/ HYD. PANTOON COVER OPENING. Maintenance of Hyd. Pumps & Hyd. motors overhauling experience. Brake Linings replacement, Drum Polishing installing entire winch unit etc. BOW TRUSTER:- Maintenance of Hydraulic Oil in tank. Taking care of any overloading alarm during running and immediate action. Taking care of any abnormal angle for activation. Immediately stoppage / warring to Bridge reminding of more than 35 RPM main engine. Strict watch and keeping sharp eyes of any accumulation of water in the Bilges of Bow Thruster Room. Immediately investigating the reason. This will prevent Bow Thruster Electrical Motor immersing in water / getting short circuited. RTD Thrusters, Star Jet Gill Thruster and Rim Enclosed propellers. Babul propellers mounting (one ahead &one astern direction. I.O.P.P SYSTEM:-Experience with confidence in complete dismantling of plant stages filters replacement, COLASCER filters replacement, relief valves maintenance and baffles plate’s replacement. Inspection of all probes and changing them.15 ppm alarm and pump stoppage on alarm. Maintenance on oil monitoring device by cleaning lenses.

- 4. FRIDGE / AIRCONDITION PLANTS;- Air-conditioning Plant compressor dismantling, valves plates overhauling/ replacement. Pistons & piston rings replacement, Crank shaft bearings replacement, crank journal bearing replacement. Reassembling/ Installation of complete plant. Evaporator net chemical cleaning. Solenoid valves replacement maintenance, filters replacement. Vacuuming the system. Refilling the system. Nitrogen washing. Working on all gases examples R-12. R-24, R-404 etc. MAIN ENGINE PNEUMATIC MANOEUVRING SYSTEM FAULT DETECTION, PNEUMATIC CONTROL SYSTEM PARTS REPLACEMENT. ADJUSTMENT OF PNEUMATIC VALVES. MAINTENANCE OF VALVES PARTS RENEWAL. FIRE MIST SYSTEM FOR EXTENGUISHING:- Maintaining water level in the tank keeping strict watch on the sounding and capacity of water. Maintenance of pump multistage impellers replacement of impeller, renewal of mechanical seal. CO2 TOTALL FLOODING SYSTEM:- Strict check on the system, operating every Saturday routine alarms sound, on door opening. Checking Air Dampers shut operation, Fuel valves shut off operation, Fuel Pumps shut off operation, and Air Blower Fans shut off operation. Greasing all wires and pulleys, measuring the weight of gas every year in each bottle. Checking whole Battery manual operation. HIGH EXPANSION FOAM SYSTEM ON SMALL TANKER VESSEL:- Testing the foam mixture every week. Maintenance of expansion foam pump. Checking relief valve, valves and all mountings on high expansion foam pressurized tank. INERT GAS GENERATOR:- Checking diaphragm valves, relief valves and regulating valves. Replacement of all valves. Checking all pipe lines passages to all tanks on oil tanker. Rectifying any fault/ leakages in pipe lines. Checking pressure release valve from the main generation plant. PROFESSIONAL FRIDGE UNITS ON [ LPG / LNG ] CARRIER:- V-shape compressor 6units, W-shape fridge compressor 9 units all Makes and types reciprocating/ centrifugal / Scroll type fridge compressor. Maintaining the inside temperature of Cargo Gas Tanks. Rectifying any alarm condition immediately. Maintaining temperature range [-196 C____ +50 C] for LIN. Purging. Major responsibility as a marine Chief Engineer on slow speed main engine of make Mitsui B&W 6LGFC67,6LKFC67, SULZER RD, RND & RTA SERIES, MAN/B&W MC , LMC & SLMC SERIES. Main Engine cylinder units overhauling, cylinder liner replacement, cylinder jacket ring replacement, fuel injectors overhauling, air starting valves overhauling, exhaust valves overhauling and reinstallation on Main Engine. Main Engine relief valves/safety valves overhauling and reinstallation. Fuel linkages and Governor Linkages lubrication and checked free moments. Maintenance of electro-pneumatic maneuvering system filter cleaning, parts renewal. Dismantling of main bearings, bottom end bearings, crosshead bearing s and thrust bearing for survey and reassembling. FLY WHEEL THRUST BLOCK PADS REPLACEMENT & CLEARANCES RECORDS KEEPING. M/E TURBOCHARGER:- ABB/BBC TURBO CHARGERS VTR-601,VTR 801, VTR- 501, VTR-251 & VTR-354-32 Overhauling of turbocharger, cleaning of inside casing, replacement of Lybrith Seals, Blower/ Turbine bearings, Oil pumps overhauling, Measuring K,L & M clearances. Keeping K distance as per Maker. AUXILIARY ENGINES:- (Daihatsu Diesel 8 PSHTB 26D 1000BHP, 720 RPM& 580 KVA), RUSTON, SULZER 8units and B&W 6 units. A/E M.A.N B&W TYPE 6L23/30H, 900 KW. Complete overhauling, connecting rods, cylinder heads, pistons, cylinder liner, fuel injectors, air starting valves, inlet valves & exhaust valves with replacements. Crank shaft inspection, running gears inspection, hammer testing and crank shaft deflections as per schedule maintenance. All related safeties and emergency shut-down tests as per schedule maintenance. Camshaft profiler replacement, vibration damper replacement. Also Gas Engines for power generation , its operation and maintenance. INERT GAS GENERATOR:- Maintenance of Boiler nozzles, pilot & main burner nozzle. Cleaning of showering nozzles decarburizing of inside IG plant. DECK SEAL:- Inspection inside the seal tank water supply pipe passage clearance checked. Water supply pressure checking. Floating cylinder operation checking. P/V BREAKER:- P/V Breaker checking its flap operational moments checking.

- 5. RESPONSIBILITY AS CHIEF ENGINEER / TECHNICAL SUPERINTENDENT To organize safe discharge of IFO & MGO from vessel to another vessel. To maintain the continuous discharge from the vessel to another vessel without any delay. To maintain the oil tanker for RUSTANURA (SAUDI ARABIA) safety inspectors. To make ready all the safety and firefighting equipment, display all the posters all over the essential places, safe working procedures use of equipment and place of equipment, specified duties and awareness of all engine room escape routes and use of emergency escape breathing apparatus. A TEACHING EXPERIENCE IN ENGINEERING COLLEGE ( MTI- COLLEGE) Leads the operations and technical functions for the assigned fleet and ensures that all tasks are executed in an effective and timely manner. Leads the preventive maintenance planning process and monitors on a daily basis the maintenance and repair work execution of the assigned fleet. Sets and updates the yearly critical spare parts plan and ensures spare parts are available onboard RVOS’ vessels and in the warehouse. Leads the dry docking planning process, ensures work indent is prepared and approved, procures needed spare parts, and liaises with shipyard for docking preparation. Evaluates and audits the identified shipyards prior to docking implementation Attends vessels’ dry docking at shipyards, ensures proper work execution, and liaises with the Head Office for reporting and support. Ensures that the assigned vessels comply with the classification society, flag state, and contract requirements. Controls the sourcing of technical and operational supplies required for appropriate operations of the assigned fleet. Monitors and assists in incident investigation and advices on corrective actions. Provides operational and technical assistance to vessels and resolves difficult issues when needed. Ensures vessels have optimum utilization rates, zero loss time, and minimal accident records, and works on preventing and eliminating potential incidents. Ensures maximum coordination between the assigned fleet and other fleets as well as the supporting functions at RVOS. Monitors and guides the Port Captains and Port Engineers during on-hire, off-hire, and other inspections, and ensures that all observations are closed in a timely manner

- 6. Works closely with the HSE team to ensure successful implementation of HSE systems and policies. Promotes and disseminates a positive health and safety culture and ensures the health, safety and welfare of self and others. Ensures employee health and safety programs and guidelines are developed, regularly maintained, implemented and complied with Identifies any Health, Safety or Environmental risks and recommends and implements measures and solutions to mitigate these risks. Supports the Fleet & Technical Manager with all key operational decisions. Performs miscellaneous tasks as assigned by the Fleet & Technical Manager. Develops and institutionalizes the operational, and technical know-how, and capabilities. Promotes a highly effective management and leadership style in line with the Company’s values and that supports the achievement of its strategy and objectives. Identifies potential successor for his/her position; oversees and implements developmental plans for identified successors. I responsible for the development, performance appraisal and succession planning of all direct and indirect reports. Identifies and tracks KPIs for his function, and devises plans and initiatives for operational improvements.

- 7. CHIEF ENGINEER DUTIES ON BOARD M.T ' PRINCESS OGE', M.T' GANGA' AND M.T ' OCEAN PRINCESS-1' Maintain power for ETA & ETD stand by at Cargo loading of Chemical / Oil. Keep strict watch on IG Generator during loading. During discharging maintaining the oil temperature, strictly watch pump operation and pressure and speed regulation. In Chemical Discharging strictly watch the pump and Power Pack unit pressure, Hydraulic Motor operation and Framo pump discharge pressure. Maintaining Thermal Oil Boiler Operation discharging and storages of Bitumen, maintaining its temperature during storages and discharge time. Cleaning of Thermal Boiler (oil Circulating) nozzle, its filters pump filters and pump bearing and coupling maintenance. During Chemical Discharging checking any leakage from the main supply lines. Framo pump discharge pressure maintaining from the vessel to terminal. Maintaining Power pack unit replacement of parts and electrical pump bearing. Checking Framo-Pump wear rings seal and impeller condition. Special care given to the pump at Stripping time any abnormal sound must be notice and immediate action must be taken. Maintaining IG generator pressure specially loading oil and checking Deck seal. Maintaining the Pressure of sea water pump. Strictly watch P/V Breaker and check its flaps valve prior to operation.

- 8. MANAGEMENT AND ORGANIZATION: Manage Engine Crew for firefighting; organize them with their respective duties and stations. Arrange Engine Crew to carry out drill and observe their deficiencies and explain them their mistakes to corrective them self as per IMO rules. Educate & train engine crew for safeties and their social responsibilities. Educate and train engine crew for correct use of fire extinguisher for specific fire. Educate & train engine crew for ABANDONT SHIP drill. Educate & train engine crew for oil spillage/oil pollution. Organize SOPEP party. Manage engine crew on emergency and stand by duties during bunkering, maneuvering (port arrival) and port departure. Educate & train engine crew duties/actions during SHIP GROUNDING. Educate & train engine crew for enclosed space entry taking all preventive measures as per IMO rules. Manage engine crew for stoways search and counter bands items before sailing (port departure). Educate & train engine crew for ship security & prevention against SABOTAGE. My special responsibilities include to counter check that my engine staff wearing safety hamlet, safety shoes, boiler suit, and ear muff and gloves. Technician must be wearing glasses while working on electric grinder. Counter check technician has taken preventive measures while gas cutting and which extinguisher he is using. CONTIGENCY PLANNING: Due to risk for accident and potential consequences each ship has contingency plans for dealing with emergencies, As chief Engineer I have to educate my engine staff Summary of individual emergency procedures and indicate emergency duties. Such duties are a- Fire on vessel, LNG leakage, Hose failure, Mooring line failure, and Oil pollution. Educate and give training for situation man overboard and immediate action and Bridge Communication. Give training by drill for injured person and immediate rescue operation and possible First Aid / Medical rescue. I CAN ISOLATE AND SHUT DOWN SAFE PROCEDURE FOR WORKING IN HT LINES. I CAN DO PLANNING ON POWER PLANT. I CAN MANAGE POSSIBLE MAN POWER MANAGEMENT AND PROGRAMMING. I CAN MANAGE SHIF AND MANAGE MANNING REPLACEMENT. I HAVE A CAPABILATY OF MAN PLANNING, PERIODIC OPERATION REPORTS, RESTROATION OF POWER SUPPLY IMMEDIATELY CAPABILITY TO HANDLE ANY ACCIDENT AND RISK MANAGEMENT, MAINTENANCE, LDC CONTROL AND MAINTAINING POWER FACTOR. CAN MINIMIZE THE POTENTIAL HAZARDS, ADMINISTRATE THE DEPARTMENT ACCORDANCE WITH DELEGATED AUTHTORITY AND DECISION ACCORDING TO THE COMPANY'S POLICY.

- 9. REPORTS WRTING/CROSSP OUNDENCE CHIEF ENGINEER AUTHORIZED WORK DETAILS Voyage maintenance and performance reports on end of every voyage to Superintendent and General Manager. Dry dock complete repairs in engine room and on deck including pipes lines work, steel works, deck machinery repairs, engine room repairs and load line certificate renewal . Engine room repairs & maintenance report during port stay . Forthcoming surveys due dates report to Superintendent. Engine spares indents, stores items invoices and their ROB. Updating cards, daily engine log-book, engine record book and all papers of ISM. Updating ISM – CODE files , survey updates , PSC papers updates & emergencies. Bunker Requisition for forth coming voyage [ IFO 180 CST/ 380 CST/ MGO] calculating safe Bunker capacity by Bunker planning. Lubricating Oils Bunker requisition [M/E , A/E ] system oil. Calculating Bunker capacity in the tanks. Prepare DNV sample landing for Analysis IFO Bunker immediately after receiving Bunker. E-mail communication and immediately report any accident/ Breakdown/ or any major fault during voyage. Rectification report and prevention from such fault in future. Immediately prepared IDR and sent to company head office. Rectify the IDR and closing description. Inform the shipping for Service Engineer requirement, to rectify the fault under Warranty and immediate restore the machinery operation. Prepare economical costing and estimation for Dry - Docking / Major repairs. Prepare vessel for Internal / External Auditor planning for prevent of any NCR for the vessel. Prepare the vessel for Load Line Survey, prepare and make the items ready before Surveyor inform Superintendent by cross pounding complete program. Complete all paper works Month End and submission before 5th of Each Month. Submit the details of all received and outstanding requisitions. Submit the details of all outstanding jobs to be carried out next month. Submit each Rank Work Orders and compelled them to complete within time.