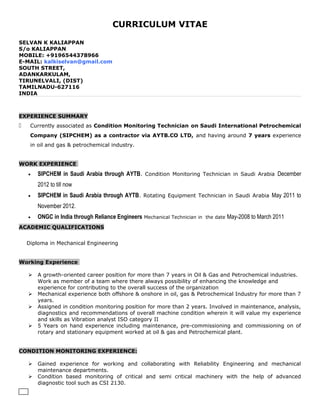

7+ Years Oil & Gas Experience Mechanical Technician CV

- 1. CURRICULUM VITAE SELVAN K KALIAPPAN S/o KALIAPPAN MOBILE: +9196544378966 E-MAIL: kalkiselvan@gmail.com SOUTH STREET, ADANKARKULAM, TIRUNELVALI, (DIST) TAMILNADU-627116 INDIA EXPERIENCE SUMMARY Currently associated as Condition Monitoring Technician on Saudi International Petrochemical Company (SIPCHEM) as a contractor via AYTB.CO LTD, and having around 7 years experience in oil and gas & petrochemical industry. WORK EXPERIENCE • SIPCHEM in Saudi Arabia through AYTB. Condition Monitoring Technician in Saudi Arabia December 2012 to till now • SIPCHEM in Saudi Arabia through AYTB. Rotating Equipment Technician in Saudi Arabia May 2011 to November 2012. • ONGC in India through Reliance Engineers Mechanical Technician in the date May-2008 to March 2011 ACADEMIC QUALIFICATIONS Diploma in Mechanical Engineering Working Experience A growth-oriented career position for more than 7 years in Oil & Gas and Petrochemical industries. Work as member of a team where there always possibility of enhancing the knowledge and experience for contributing to the overall success of the organization Mechanical experience both offshore & onshore in oil, gas & Petrochemical Industry for more than 7 years. Assigned in condition monitoring position for more than 2 years. Involved in maintenance, analysis, diagnostics and recommendations of overall machine condition wherein it will value my experience and skills as Vibration analyst ISO category II 5 Years on hand experience including maintenance, pre-commissioning and commissioning on of rotary and stationary equipment worked at oil & gas and Petrochemical plant. CONDITION MONITORING EXPERIENCE: Gained experience for working and collaborating with Reliability Engineering and mechanical maintenance departments. Condition based monitoring of critical and semi critical machinery with the help of advanced diagnostic tool such as CSI 2130.

- 2. Working on CSI-2130 Software (Machinery Health Manager) Software as Administrator. Installation of Software, Creation of Database, Field data collection and analysis on CSI-2130 Generate lube oil analysis report according to the results provided by Laboratory Root Cause Analysis, Case Histories and record keeping with Machinery history, specs and OEM limits. Work with other disciplines to investigate and identify maintenance faults and propose solutions to prevent re-occurrence Setting up office documents, procedures, maintenance requirements, Job Safety Analysis, Risk Assessment and preparing workshop’s tools and equipment Worked together with project division for commissioning, Site acceptance test and be a part of safe successful plant start up. Providing a high reliability and availability of all rotating equipment during steady state operation. Assisted vendor for Hot spot inspection on critical equipment i.e. turbine engines, compressor, and generator. Troubleshooting & guide maintenance staff to solve the Rotating & Static equipment vibration related issues Monitor and supervise the maintenance of the rotating equipment in the plant, to ensure the enhancement of its performance, availability and maintainability. Analyze and maintain the equipment parameters reading of major maintenance activities, take necessary actions accordingly in coordination with concerned department. Follow up the maintenance of the rotating equipment to ensure the quality and to check and compare data after and before repair. And performs checks on all equipment after repair or rehabilitation. MACHINERY MAINTENANCE EXPERIENCE: PUMPS Dismantling and reassembling of all centrifugal and reciprocating pumps i.e. single and multi stage, vertical and horizontal, split and also barrel type. Involved in repair such as plunger changing, diaphragm changing activities such as mechanical seal assembling and aligning the pump with prime mover by Reverse and Graphical method, Rim and Face method. CENTRIFUGAL PUMPS Experience in Maintenance of single and multi stage pumps. Experience in and assembling of pumps (Boiler Feed Water pumps. lao Feed pumps, lao pumps, crude vacuum residue pumps etc, Replacing seal, Packing, Bearing etc.) RECIPROCATING PUMPS Experience in Maintenances plunger pump chemical dosing pumps, doublet, triplex pumps, gear pumps, Diaphragm and zirconium injection pump etc. amine pump, EASC pumps, Experience in Assembling and dismantling pumps. COMPRESSOR Overhauling air and gas compressor both rotary as well as reciprocating, maintaining the required clearance for piston ring gap. Changing gas seal cups, bearing, suction and discharge valves as well as maintenance of lube oil circuit and coolers. STEAMTURBINES Carried out preventive maintenance on their accessories, steam is a byproduct and save electricity. Impulse and reaction two types, and HP and LP turbines the steam nozzle clearance and blade deflector clearance, governor system, shutdown tripping system, maintaining.

- 3. MECHANICAL SEALS Worked on all types of seals including single, double and tandem seals, single spring and multi- spring, Bellow type and proper rectification of the same. Compressors in ISO carbon seals GEAR BOXES Involved in preventive maintenance and bearing changing inspection of gas and bearing and check the back lash clearance activities. ALIGNMENT Alignment of pumps ,compressors and turbines suiting Hot and Cold condition By: Rim and Face Method Reverse dial indicator Method Laser method Pump Operation Operations of Centrifugal & Reciprocating pump open Start up & shut down. Maintenance seal check, Cavitations, Suction & Discharge pressure check-up, pulsation chamber, Strainer operation coupling Lube pump operation, oil level maintenance, and vibration check. Shaft vibration & Heat check-up, speed setting chemical dose pump operation, submersible pump operation, trouble shooting, etc Operations and Maintenance to single Pump and multistage Pumps. Experience in Dismantling and assembling of Pumps Replacing seal, Packing, Bearing etc Assembling and dismantling of pumps. Experience in maintenance of plunger pump chemical dosing pumps, duplex, triplex pumps, caustic pump, gear pumps, Diaphragm and toluene injection pump Key Deliverables Conducting routine checkup of all equipment & units to ensure the functioning of the equipments in accordance with standard operation procedure. Tracking all equipment and instrument for defects and leaks immediately & taking as well as suggesting possible corrective action. Overseeing a gamut of tasks encompassing following activities: Maintaining a record the mechanical log sheet each and every hour. Checking the water and Oil interface level in Separator Sump tank. Hydro Testing of pipe Line PERSONAL VITAE

- 4. Date of Birth : 06-01-1988 Marital Status : Single Language Known : English, Hindi, & Tamil. Mobile : +966544378966 Nationality : Indian. Passport No : H1224175 Valid Up to : 14-10-2018 Passport Status : ECNR Declaration I here declare all that information is true and best of my knowledge. Place: INDIA Yours Faithfully, Date: Selvan K Kaliappan