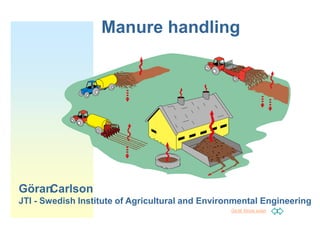

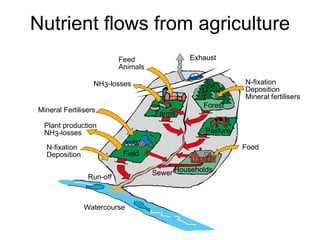

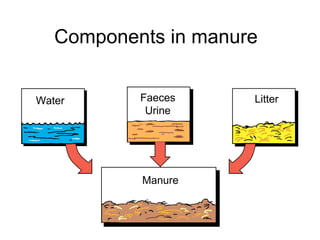

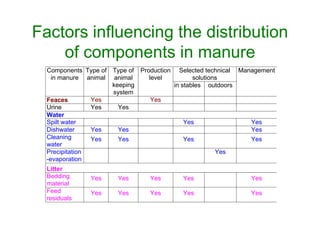

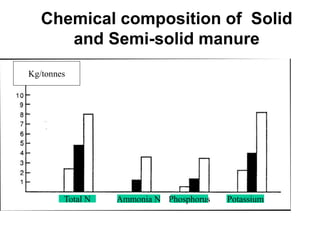

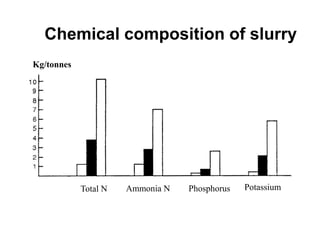

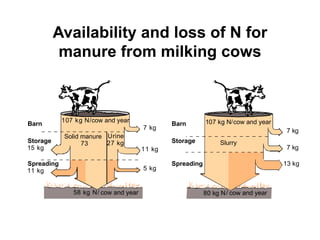

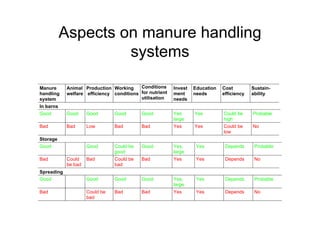

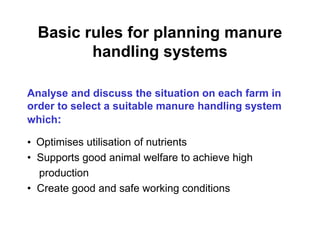

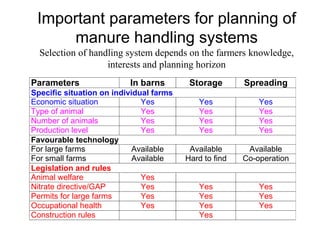

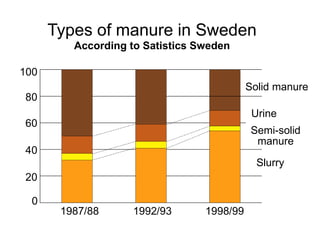

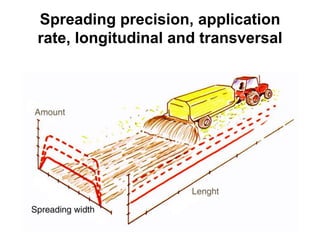

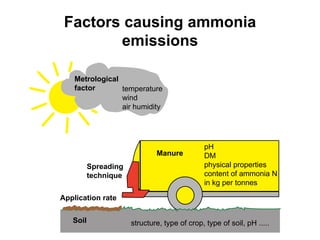

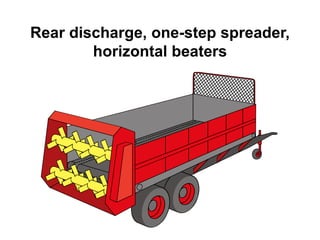

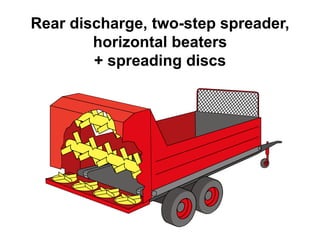

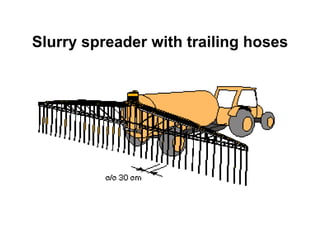

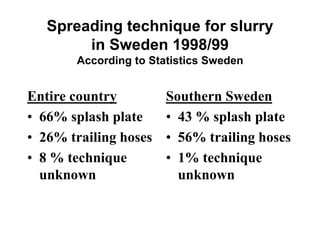

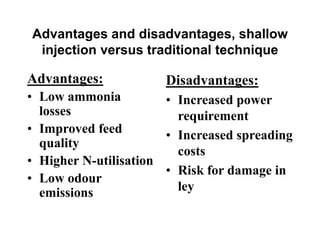

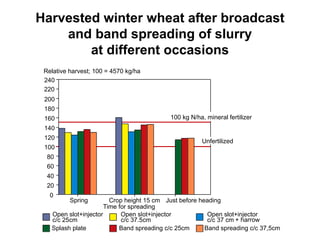

This document discusses manure handling and management. It covers the components of manure, factors that influence manure composition, chemical composition of solid and slurry manure, nutrient availability from manure, aspects of manure handling systems, parameters for planning handling systems, and methods of manure spreading. The document provides information on optimizing manure use and minimizing losses to improve nutrient utilization and environmental impacts.