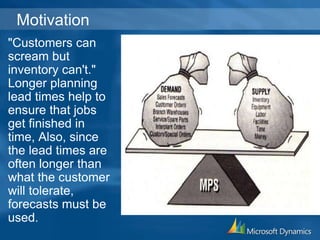

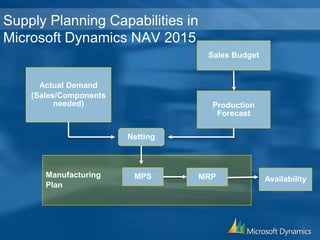

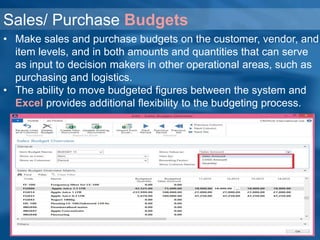

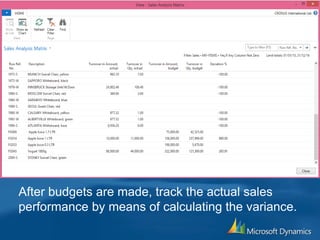

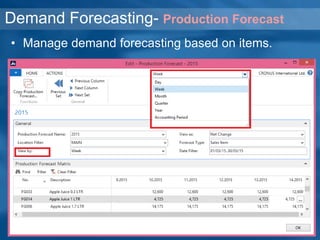

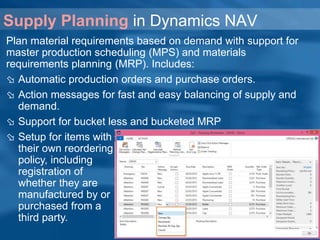

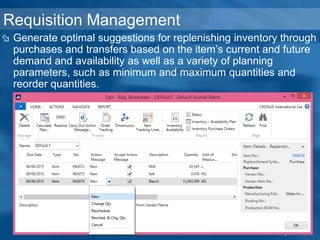

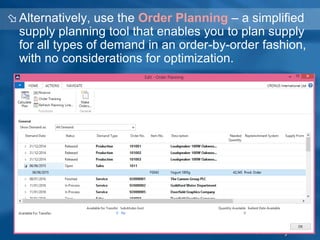

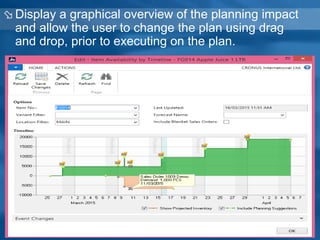

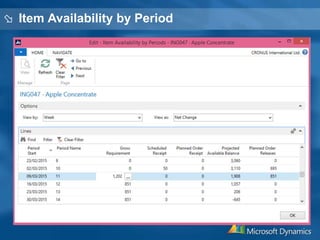

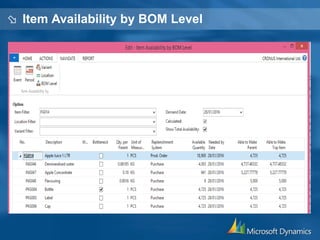

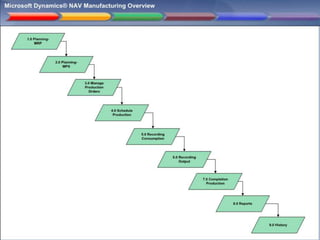

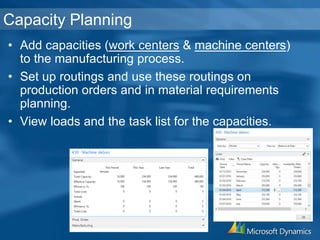

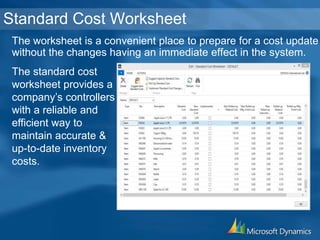

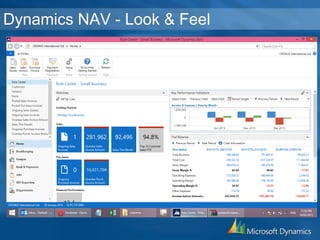

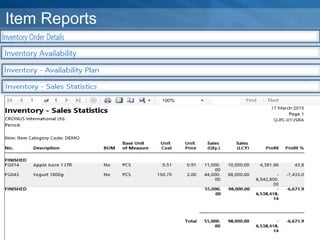

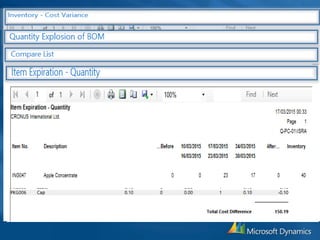

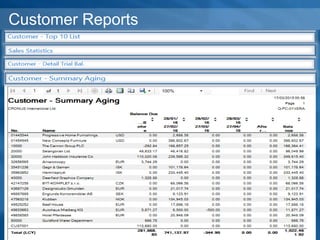

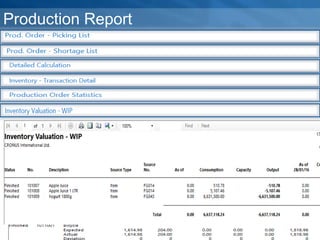

This document summarizes the key capabilities of Microsoft Dynamics NAV as an ERP solution, including its modules for orders processing, planning and forecasting, manufacturing, and reporting. It describes functions for purchase order management, sales order management, production orders, demand forecasting, supply planning, order promising, bills of materials, capacity planning, and standard cost worksheets. Visualizations for item availability and a report designer are also highlighted.