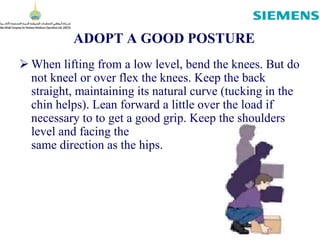

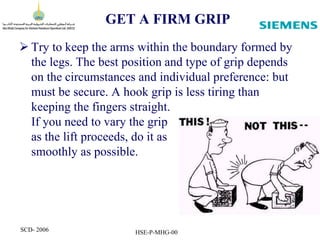

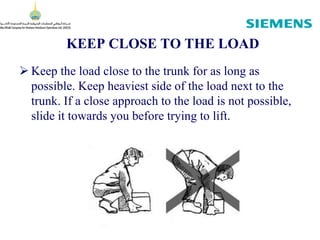

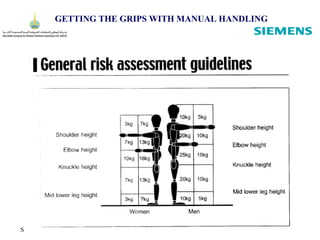

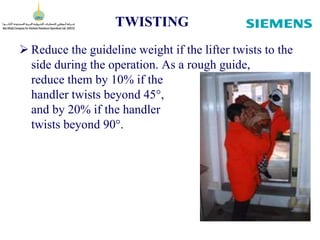

This document provides guidance on proper manual handling techniques to prevent back injuries. It outlines risks associated with improper handling, such as more than a third of over three-day injuries being caused by manual handling. The document instructs employees to avoid hazardous manual handling where possible, assess risks, and reduce risks of injury. It provides guidelines for safe lifting and lowering based on weight and frequency of lifts to assist with risk assessment. Proper techniques like bending knees, keeping a straight back, and lifting smoothly are emphasized.