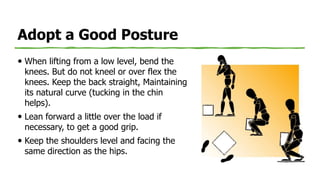

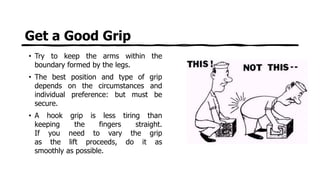

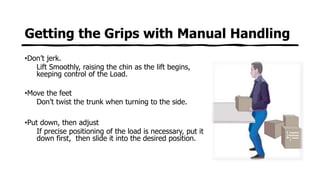

This document provides information on manual handling dangers and controls. It discusses what manual handling is, common manual handling injuries, and how to properly assess risks and lift loads safely. The key points are to lift with the legs, keep the back straight, avoid twisting, get help for heavy loads, and use load handling equipment when possible to minimize manual handling risks and injuries.