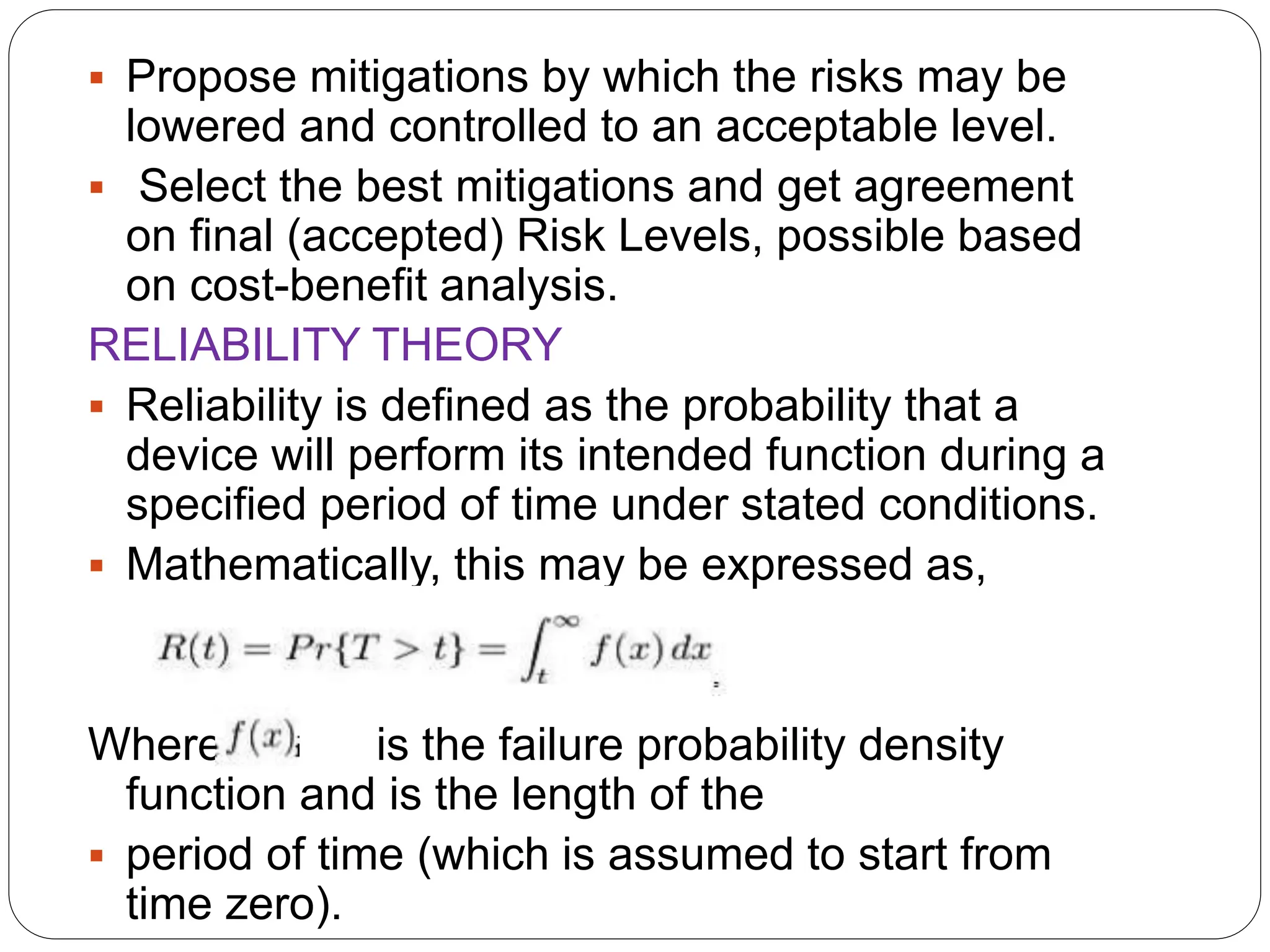

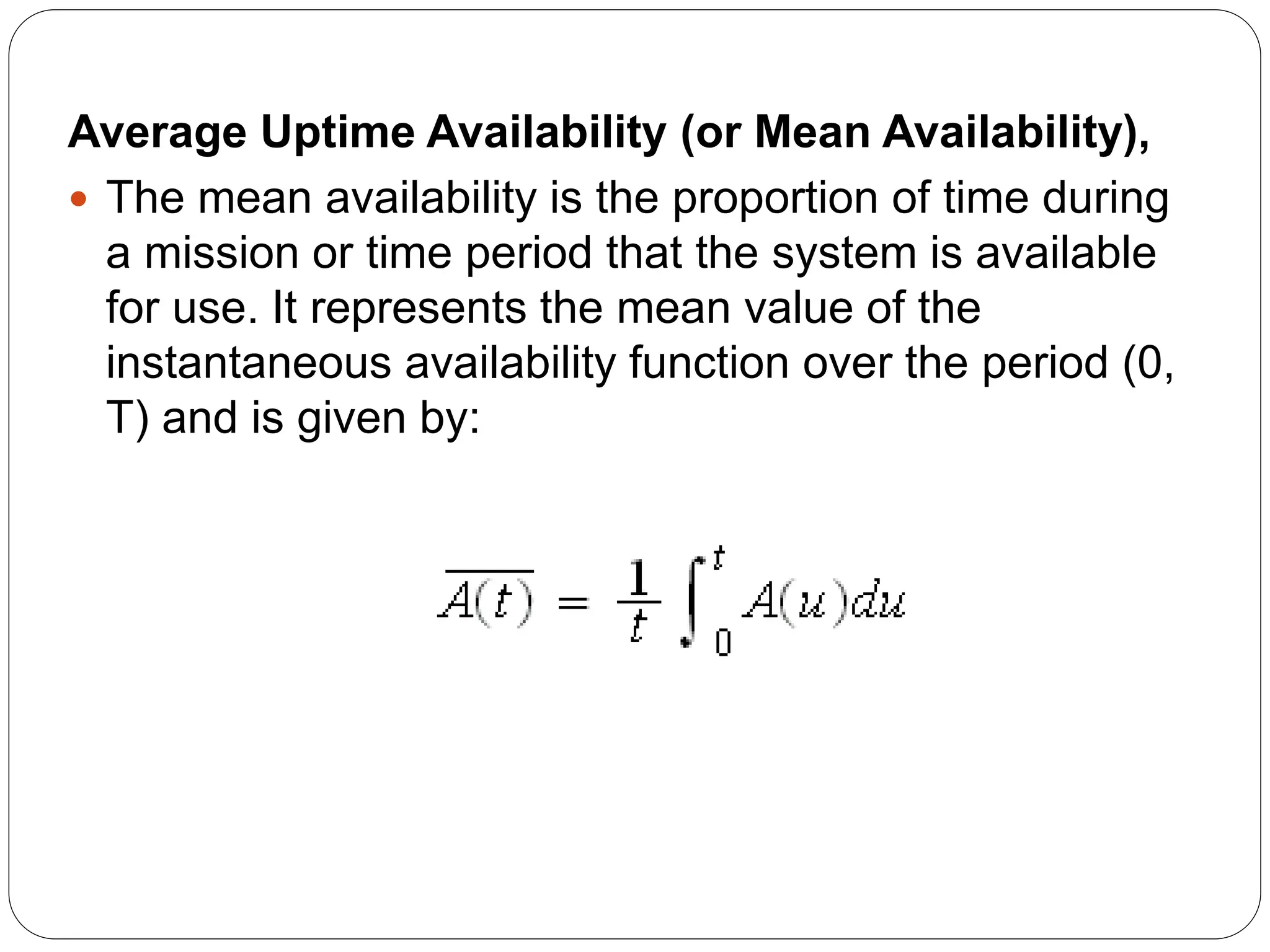

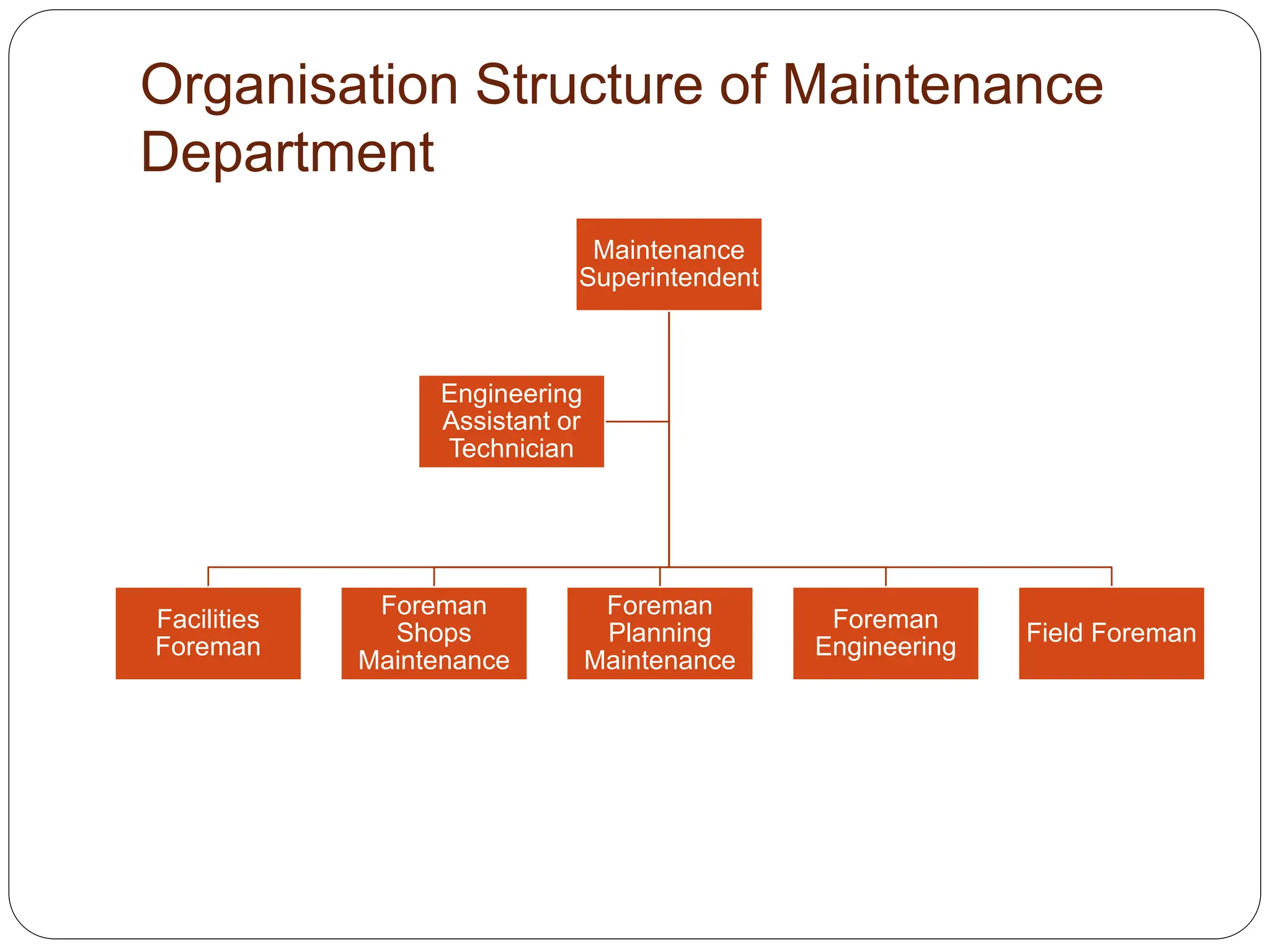

The document discusses maintenance engineering principles and practices. It covers objectives of maintenance planning which include maximizing production availability and minimizing costs. It also discusses reliability concepts such as MTBF, MTTR, and availability. Different types of maintenance organization structures are described such as decentralized, centralized, and partially centralized models. Key aspects of maintenance such as maintainability, availability calculations, and factors affecting them are explained.