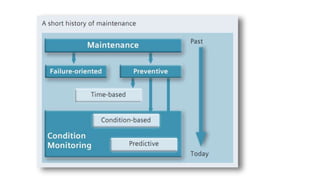

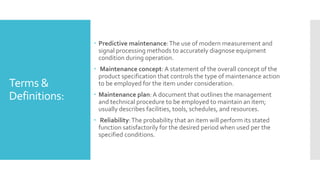

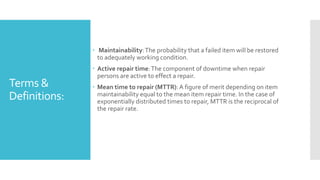

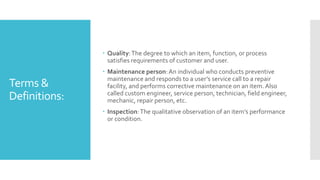

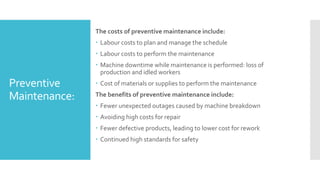

This document discusses various types of mechanical maintenance including preventive, corrective, operational, and lubrication maintenance. Preventive maintenance aims to maximize equipment availability and minimize defects by addressing potential issues before they arise. Corrective maintenance repairs equipment after failures occur. Operational maintenance includes inspecting, cleaning, and minor adjustments. Regular lubrication is important as it can decrease early bearing failures and increase bearing life. Proper maintenance helps keep equipment safe, reliable, and productive while avoiding high costs of unexpected breakdowns.