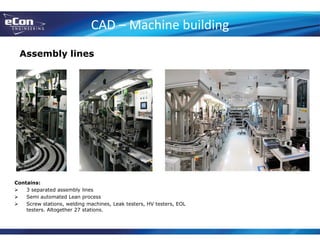

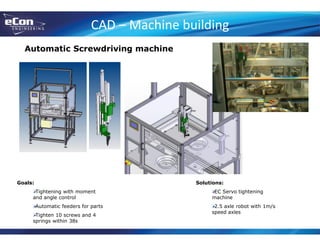

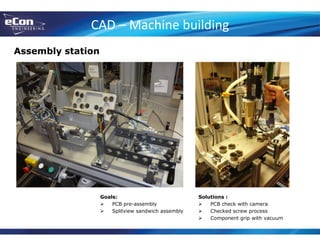

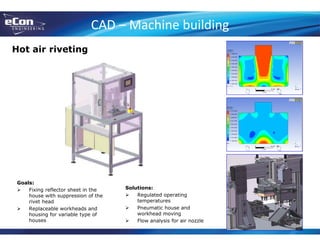

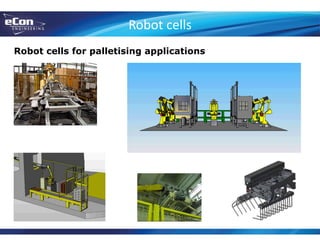

This document describes an assembly line for machine building. It contains several automated and semi-automated processes like screwdriving machines, cover crimping, press fitting, welding, and leakage testing. The assembly line has three separated lines with 27 total stations that incorporate screwing, welding, leakage testing, and end-of-line testing. It also describes specialized technologies like hot air riveting used to fix reflector sheets and solutions for regulated temperatures, pneumatic movement, and air flow analysis for the nozzle. Robot cells are also used for palletizing applications.