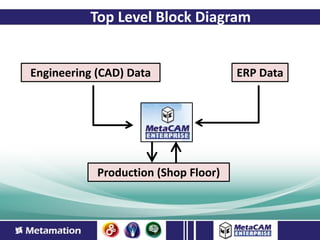

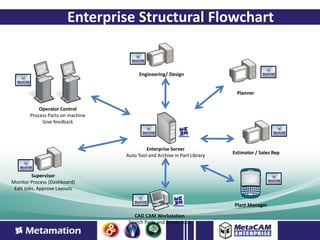

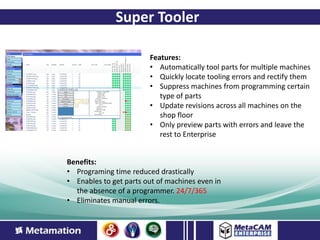

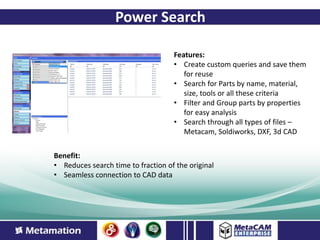

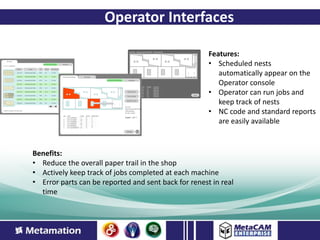

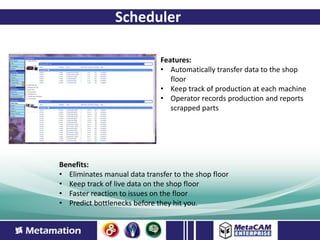

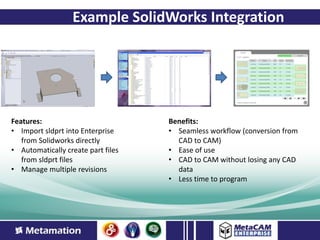

MetaCAM Enterprise is a production management software that integrates engineering data, ERP data, and production operations on the shop floor. It aims to automate and streamline traditional manufacturing processes like part programming, file storage and retrieval, revision tracking, operator interfaces, scheduling, and data analysis. Key features include automatic part programming to reduce errors, powerful search capabilities for engineering files, real-time revision tracking, digital operator interfaces, automatic scheduling and data transfer to the shop floor, and analytics to identify bottlenecks and improve productivity. The software allows manufacturers to achieve lights-out production, reduce manual errors, and gain real-time visibility across the production lifecycle.