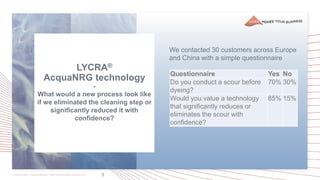

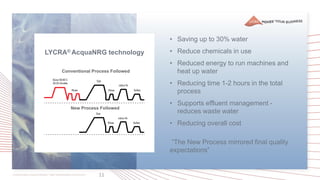

Invista's sustainability efforts focus on long-term value creation through resource efficiency, environmental protection, and employee safety, as outlined in their Planet Agenda vision. The document discusses various initiatives including energy reduction, water recycling, emissions cuts, and innovations in product sustainability, such as new LYCRA® Acquanrg technology that aims to significantly save water and energy in the production process. Invista actively engages with communities and customers to enhance sustainable practices and validate new technologies.