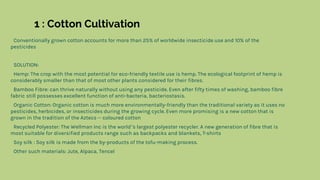

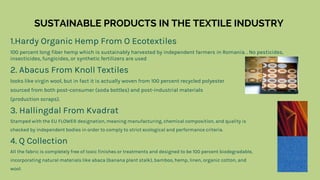

The textile industry involves the design, production, and distribution of yarn, cloth, clothing, and related products. Key players in the industry include India, China, Bangladesh, and others. The Indian textile industry is the second largest employer in India after agriculture. It contributes significantly to GDP, exports, and employment. However, the industry faces sustainability challenges across cotton cultivation, processing, and labor practices that can be addressed through methods like organic cotton farming, natural dyes, recycling, and ensuring proper working conditions. Leading brands are developing more sustainable products and processes in the industry.