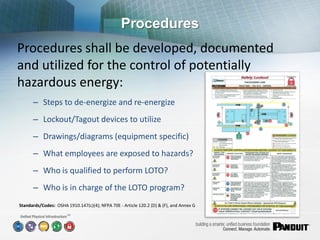

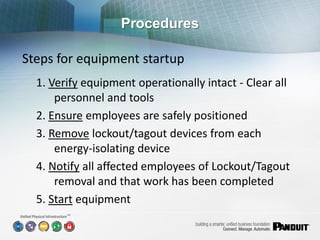

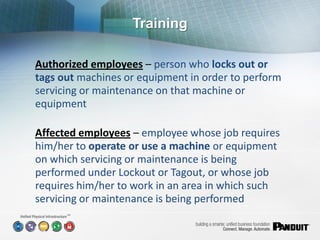

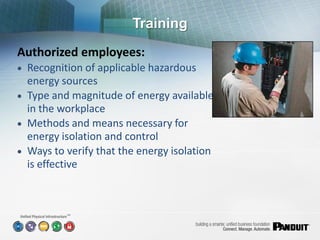

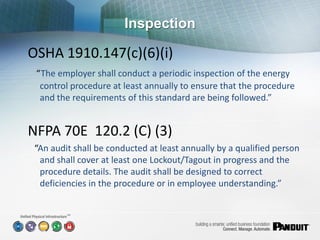

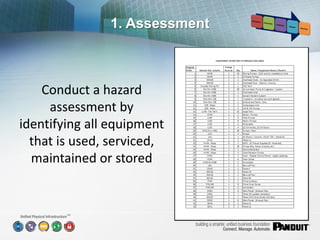

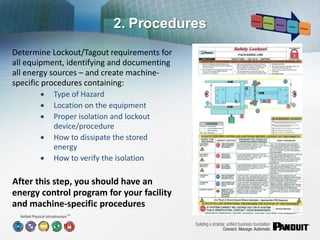

This document discusses lockout/tagout procedures and requirements. It begins by explaining that OSHA standard 1910.147 aims to control hazardous energy during maintenance. It then discusses why lockout/tagout is important for employee safety, legal compliance, and financial risk mitigation. The document outlines the key elements required for an effective lockout/tagout program, including procedures, training, device requirements, and inspections. It concludes by providing guidance on how to establish a comprehensive lockout/tagout energy control program.