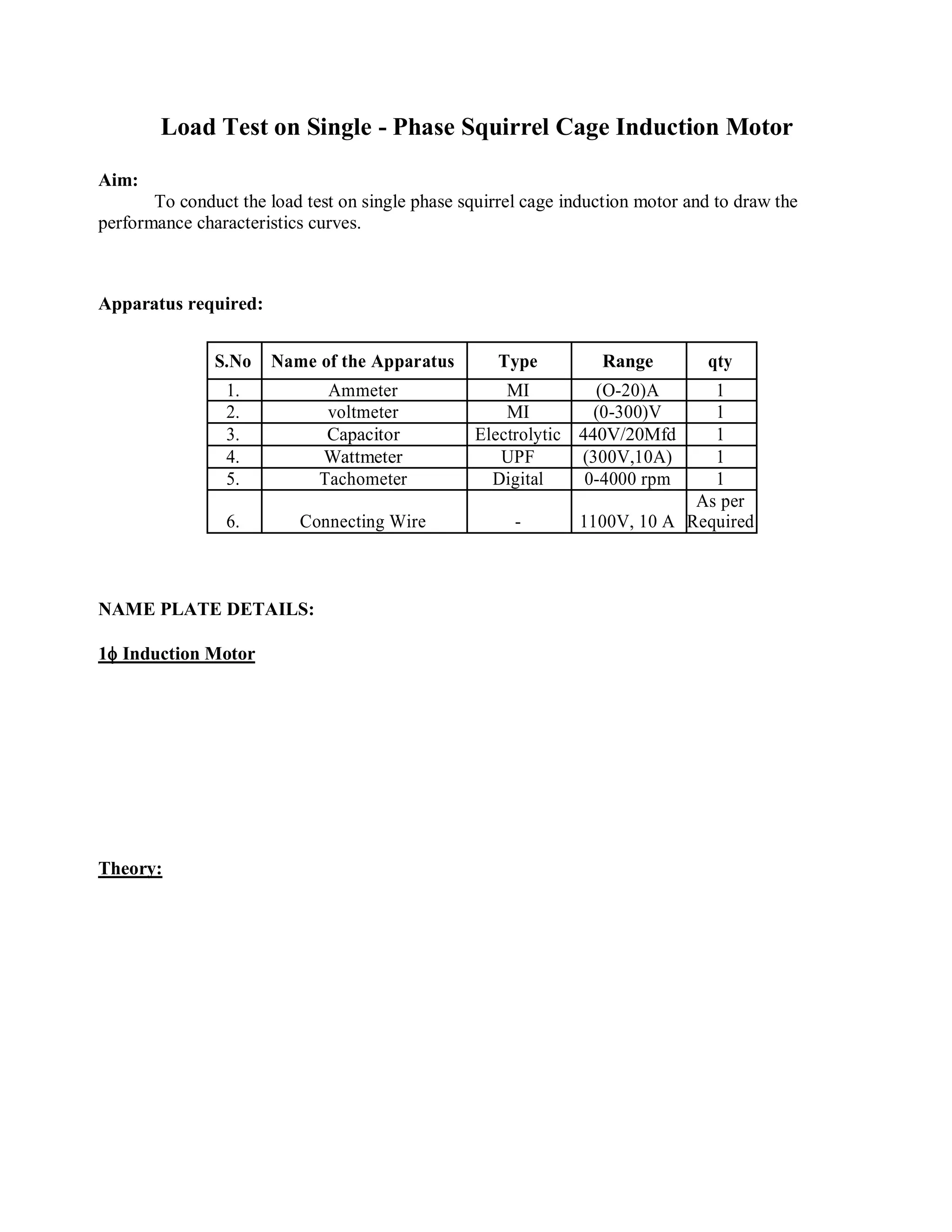

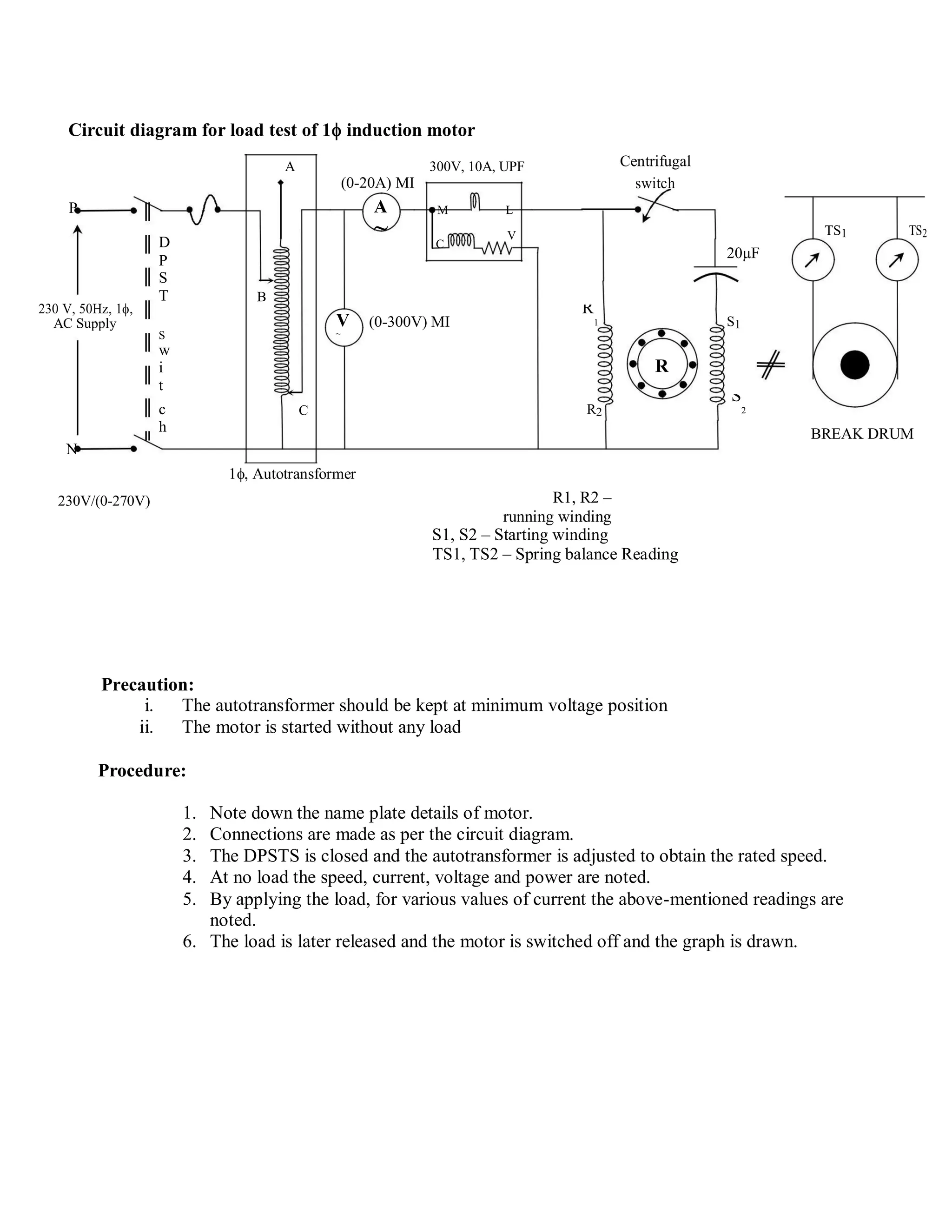

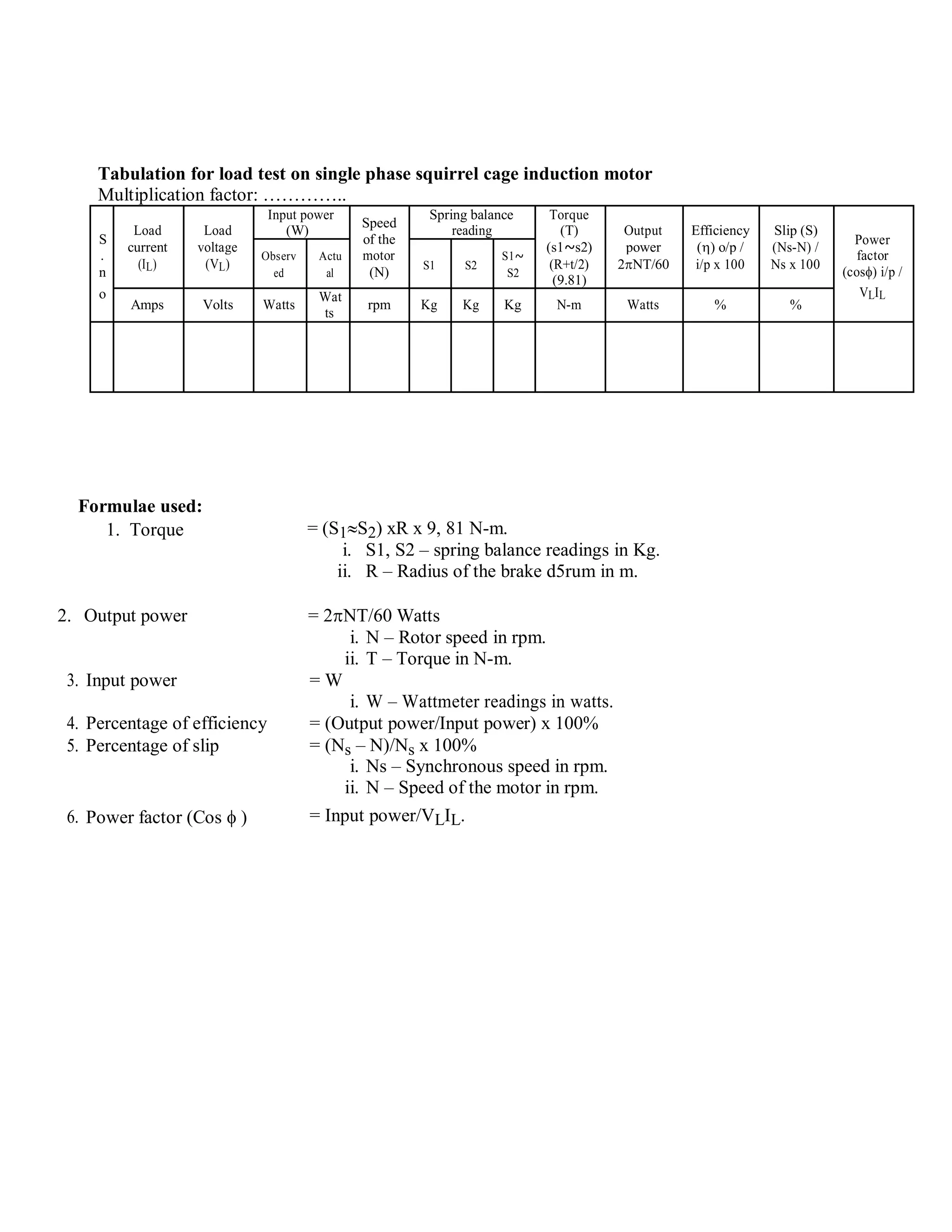

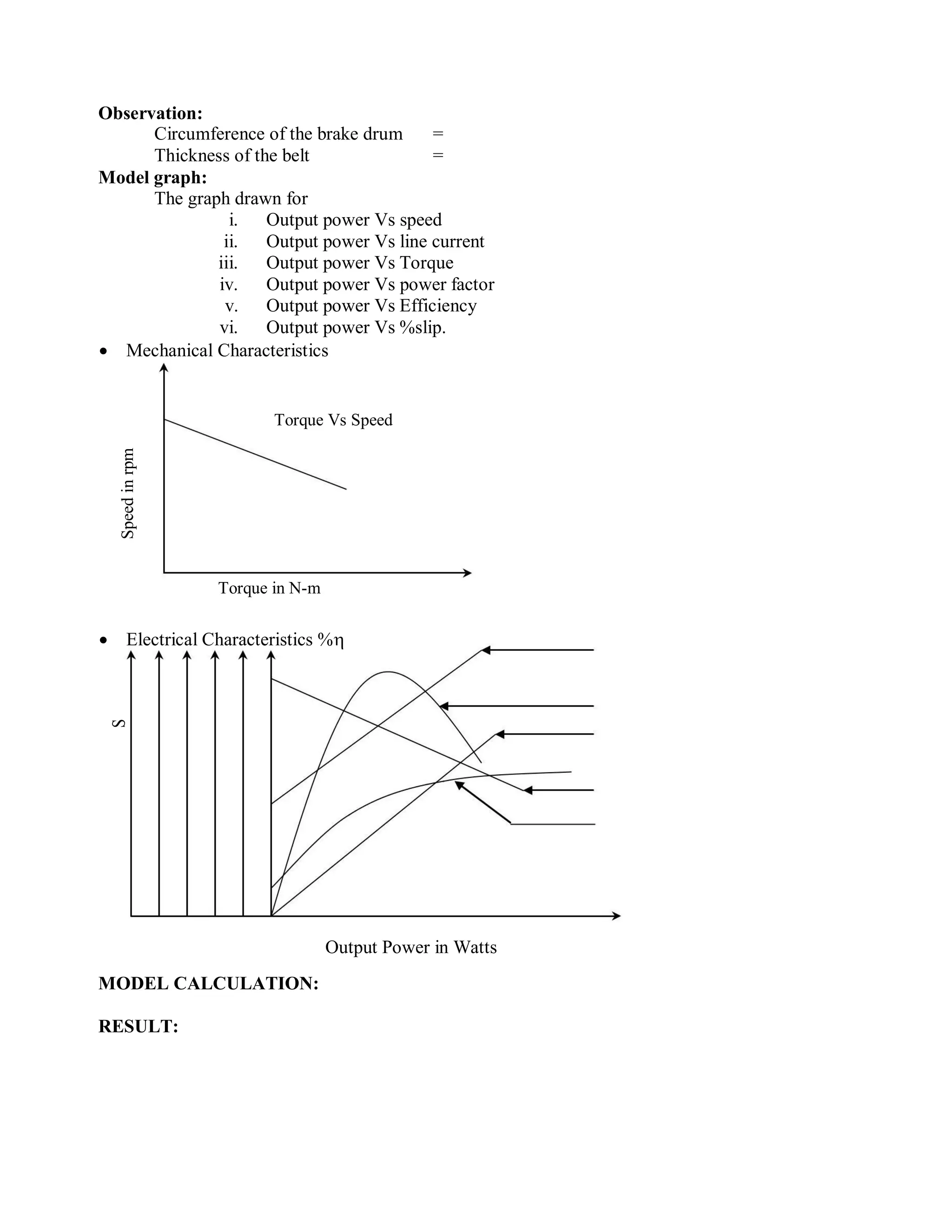

This document outlines the procedures for conducting a load test on a single-phase squirrel cage induction motor. The test involves connecting various meters like an ammeter, voltmeter and wattmeter to measure current, voltage and power at no load and various load conditions. Torque is calculated using a spring balance attached to a brake drum. Performance curves are drawn between output power versus speed, current, torque, power factor and efficiency. The test aims to analyze the motor's mechanical and electrical characteristics at different operating points under load.