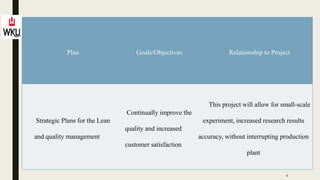

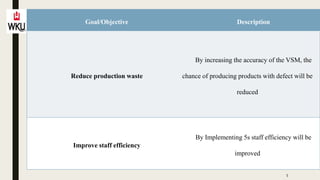

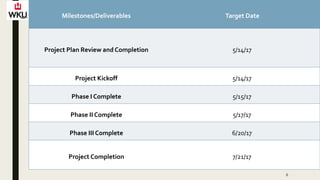

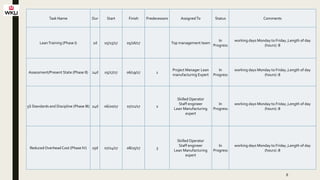

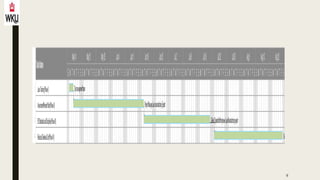

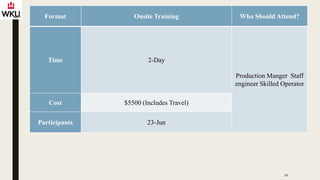

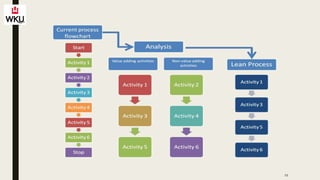

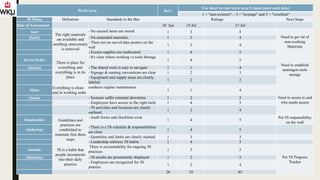

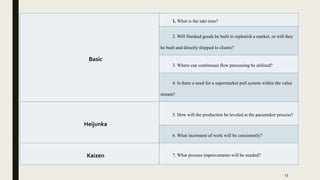

This document presents a lean project plan for improving production processes. The plan has the following goals: 1) reduce production waste by increasing value stream mapping accuracy; 2) improve staff efficiency through implementing 5S standards; 3) continually improve quality and customer satisfaction. The plan outlines phases, milestones, roles and a Gantt chart. Phases include lean training, assessing current state, implementing 5S and reducing overhead costs. The plan aims to standardize processes through 5S and establish accountability for ongoing lean practices.