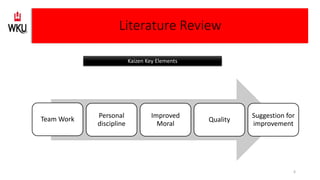

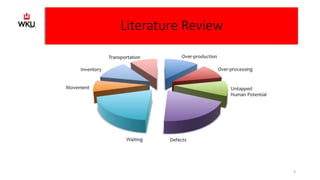

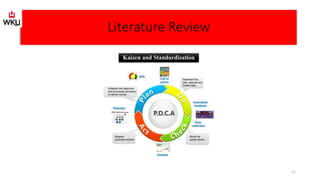

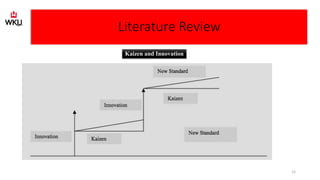

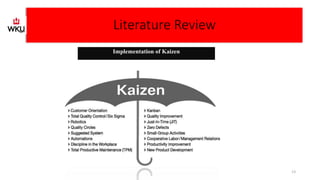

This document presents an overview of the Kaizen philosophy. It discusses the key principles of Kaizen including making small incremental changes to improve productivity and minimize waste. The literature review covers the main elements of Kaizen such as teamwork, personal discipline, and suggestion for improvement. It also examines the three M's in Kaizen - Muda, Muri, and Mura. The document outlines the steps in the Kaizen process walk and highlights advantages like reducing waste and improving quality, as well as potential disadvantages like resistance to change.