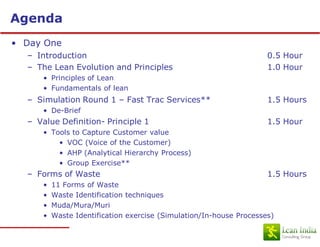

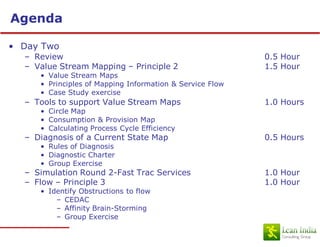

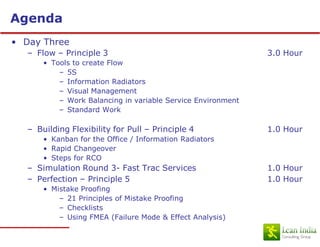

The 3-day Lean Practitioner Program Level 1 focuses on introducing lean principles and tools for office, administration and service processes. The agenda covers lean evolution, value definition, identifying waste, value stream mapping, flow, flexibility and perfection. Participants will learn through simulations, exercises and case studies. They will understand lean principles, be able to diagnose processes and identify improvement projects. Successful participants will receive a Lean Practitioner Level 1 certificate. The goal is to help organizations enhance productivity, quality and reduce costs through lean transformations.