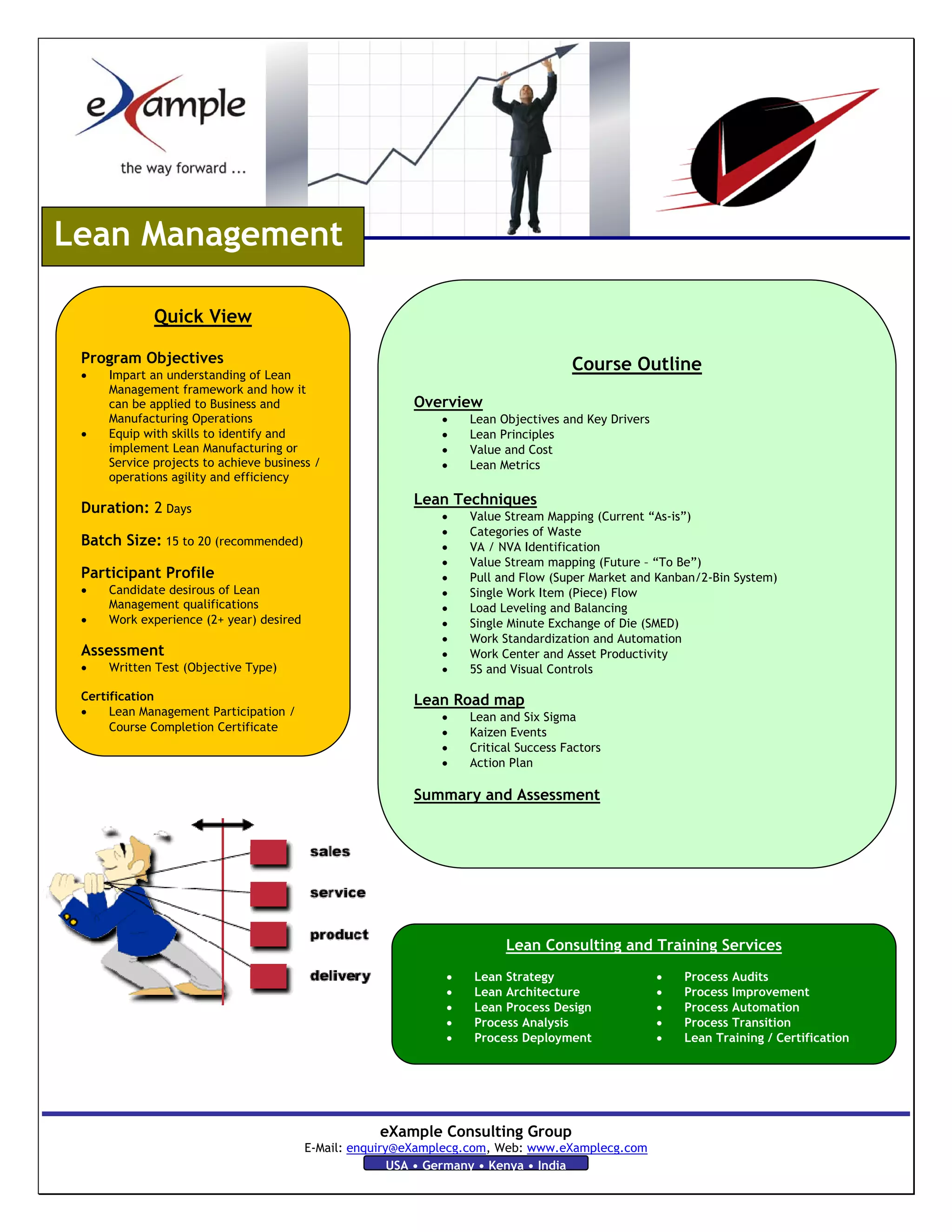

The document outlines a 2-day Lean Management training program. The program objectives are to impart an understanding of the Lean framework and how it can be applied to business and manufacturing operations. It will equip participants with skills to identify and implement Lean projects to achieve business efficiency. The course covers Lean principles, value stream mapping, waste elimination techniques like 5S, work standardization, and productivity metrics. It concludes with a Lean roadmap and assessment to help participants apply the concepts. The target audience are professionals with 2+ years of work experience seeking Lean Management qualifications.