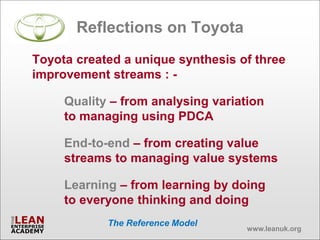

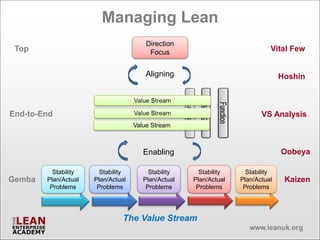

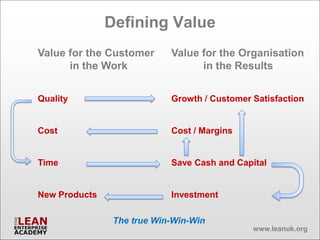

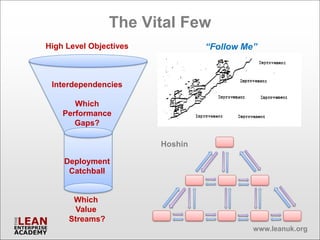

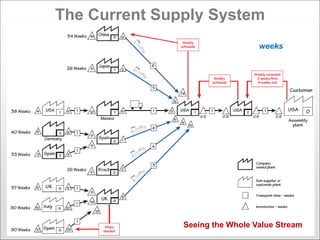

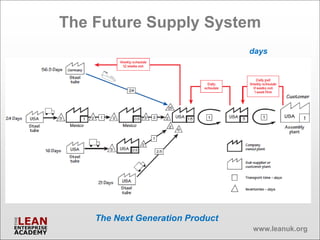

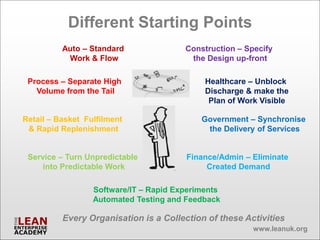

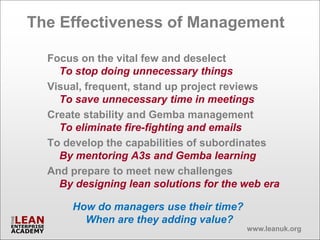

The document discusses Toyota's creation of a unique synthesis combining quality management, end-to-end value streams, and organizational learning. It presents Toyota's reference model for managing lean organizations, including focusing on vital few priorities, aligning through hoshin planning, analyzing value streams, and achieving stability through gemba management and kaizen problem solving. The model emphasizes defining value for customers and the organization, establishing high-level objectives and interdependencies, deploying through hoshin planning and catchball, and focusing on vital value streams.