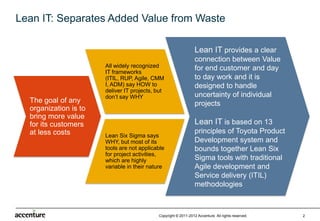

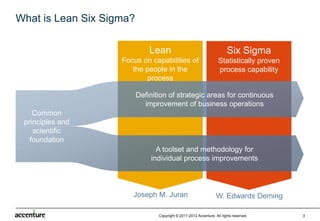

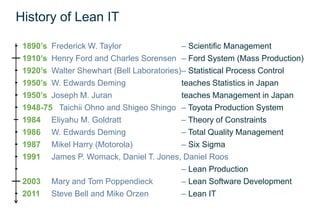

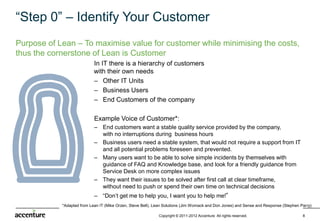

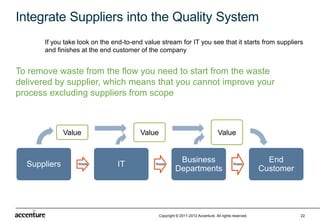

Lean IT separates added value from waste by focusing on delivering value to the end customer with less cost. It is based on Toyota's Lean principles and combines Lean Six Sigma tools with Agile development and ITIL methodologies. The first step of Lean IT is to identify the customer and understand what creates value for them from an IT service or project. This allows organizations to maximize customer value while minimizing waste.