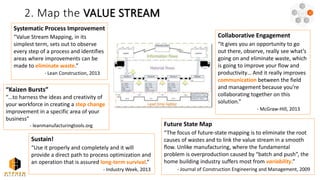

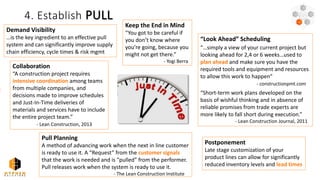

The document outlines lean principles for the homebuilding industry, focusing on maximizing customer value while minimizing waste through strategies like value stream mapping, improving flow, and establishing a pull system. It emphasizes the importance of collaboration, mistake-proofing, and preventative quality control to enhance process efficiency and responsiveness. Continuous improvement and a commitment to engaging all workers in the process are highlighted as essential for achieving long-term operational success.