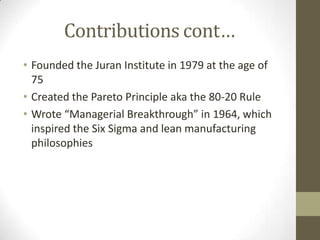

Dr. Joseph M. Juran was an influential quality management guru born in 1904 who helped develop approaches for quality improvement that are still used today. He emphasized that quality requires commitment from top management, training employees, and continuous quality improvements. Juran made significant contributions such as writing the Quality Control Handbook, developing the 10 steps for quality improvement, and founding the Juran Institute. His teachings inspired modern approaches like Six Sigma and lean manufacturing.