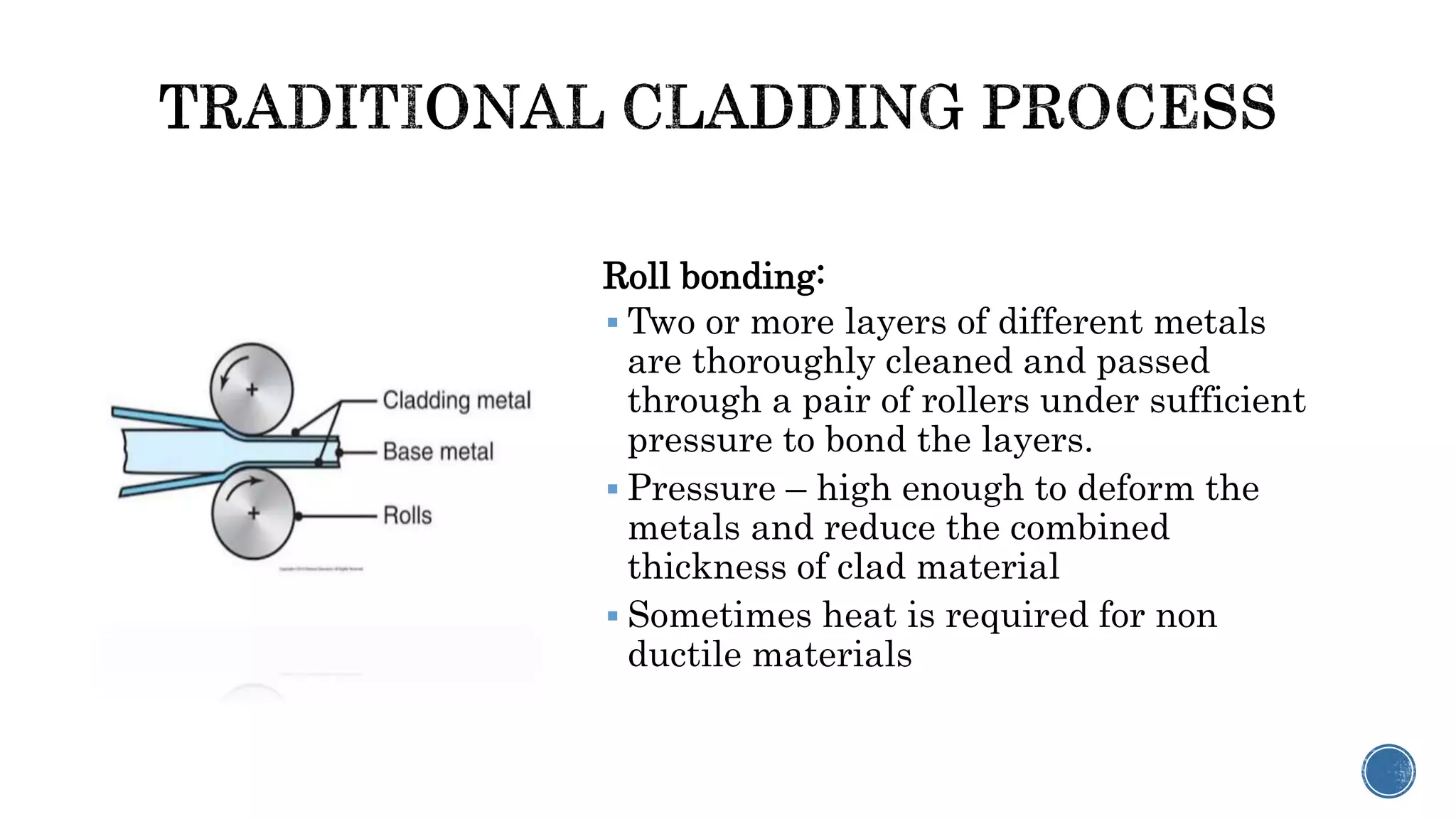

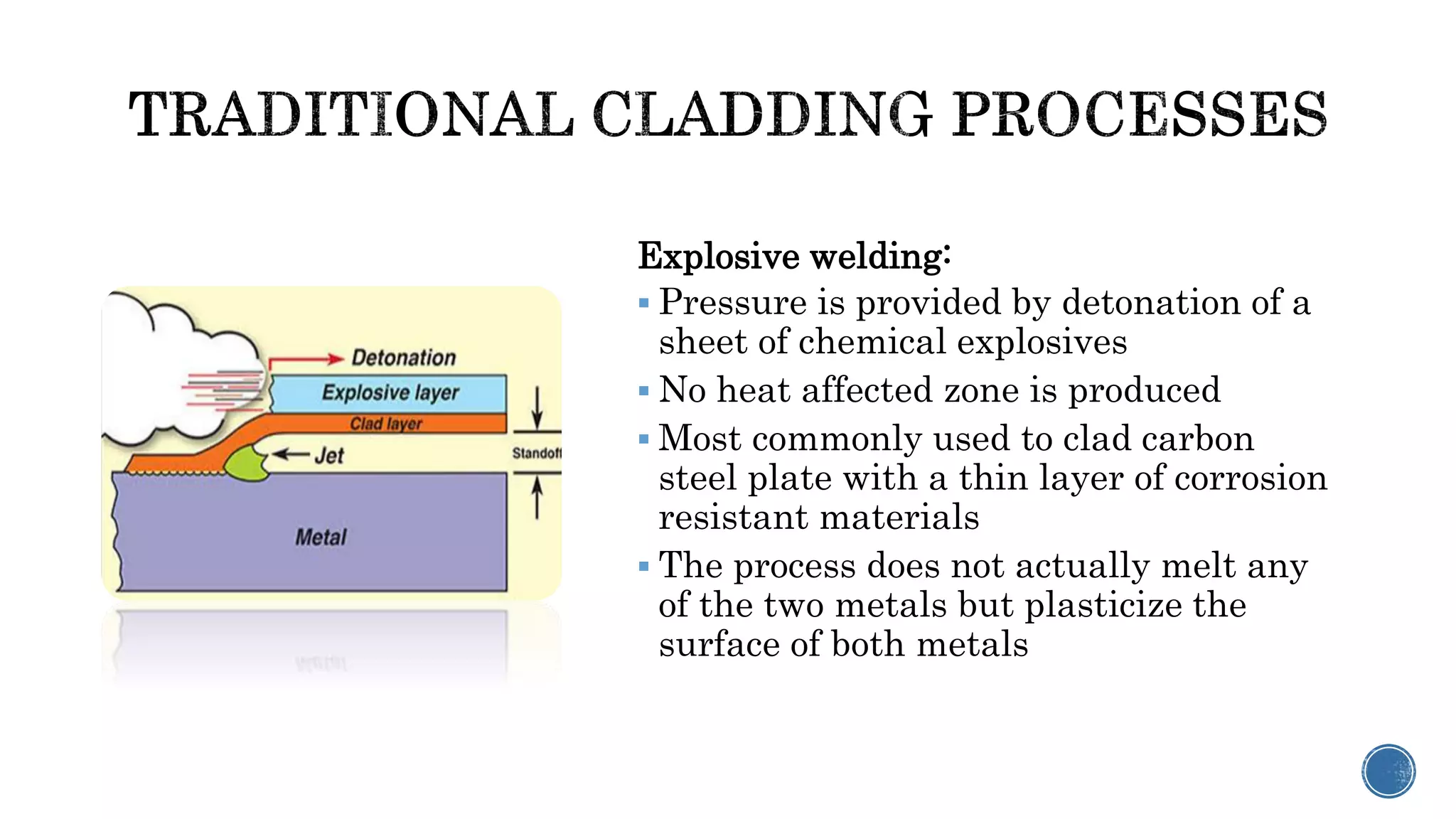

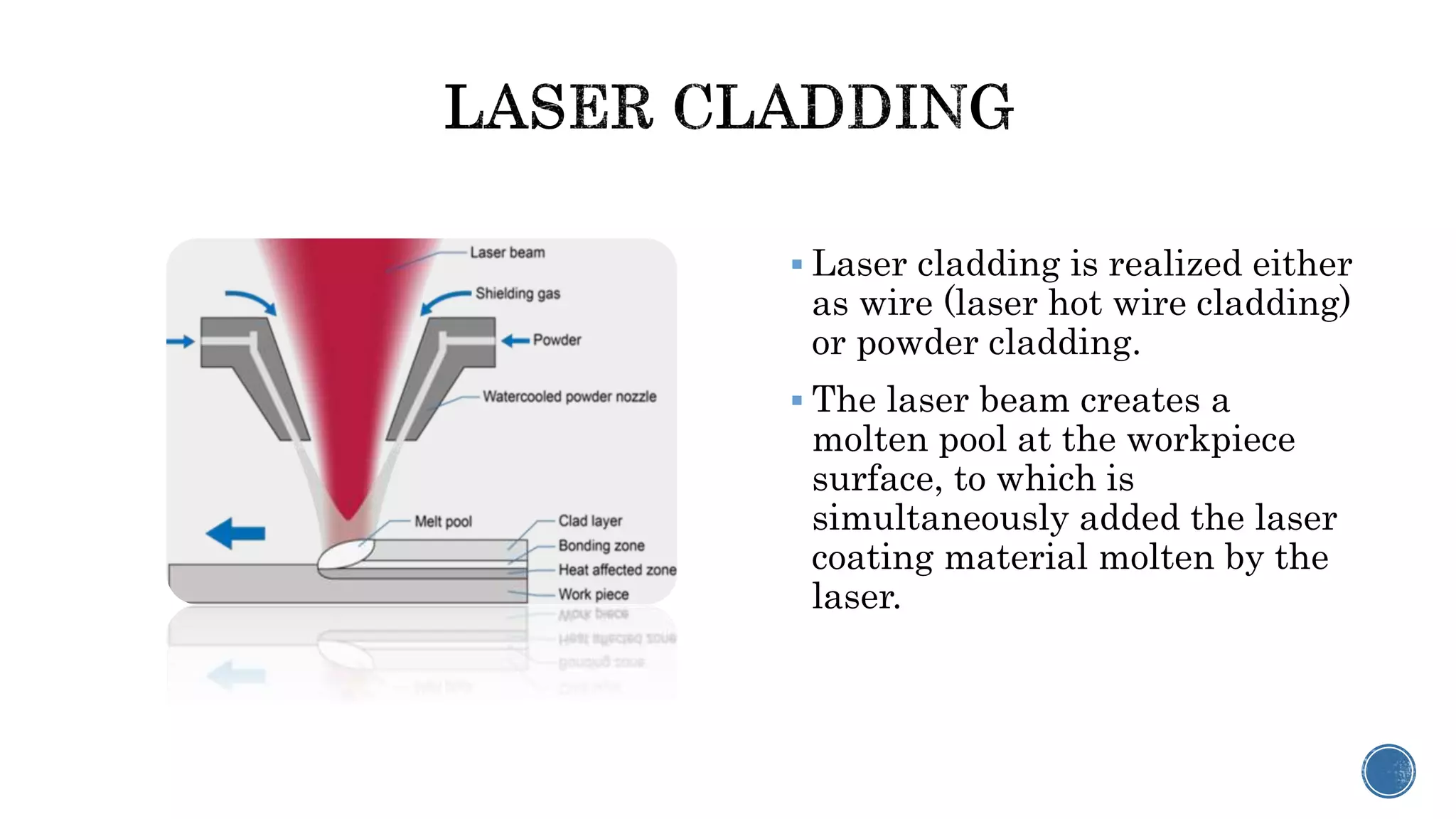

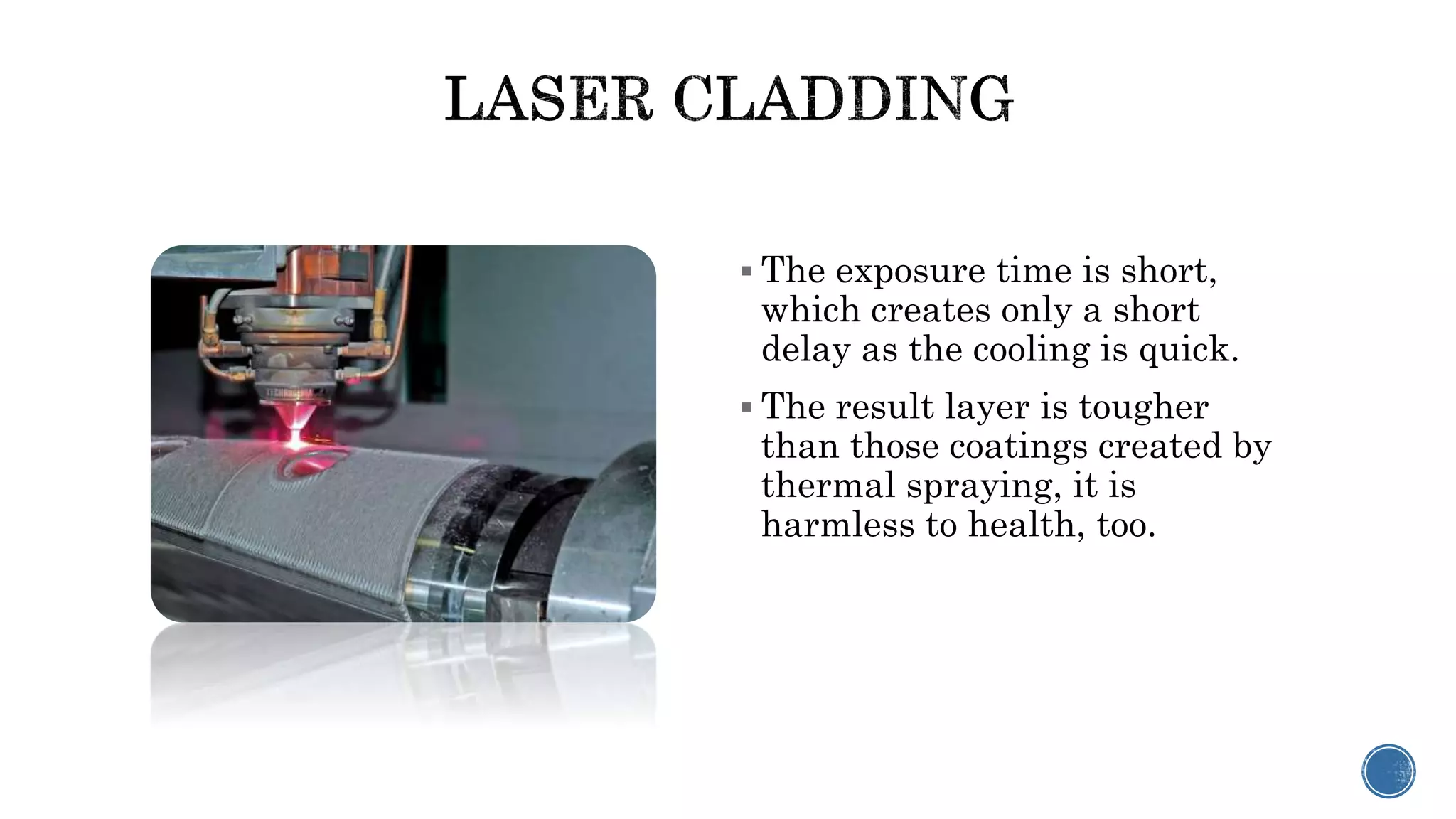

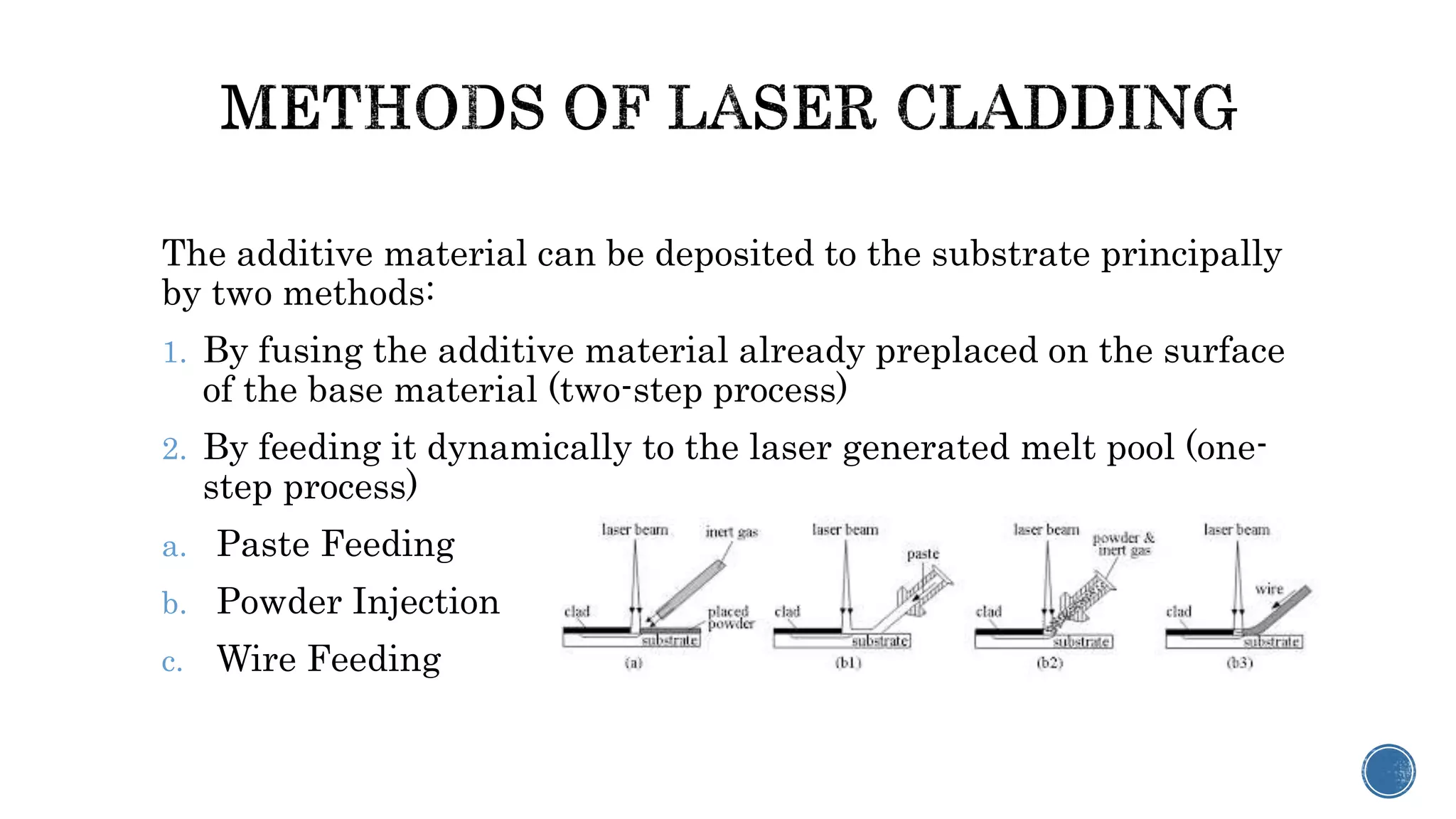

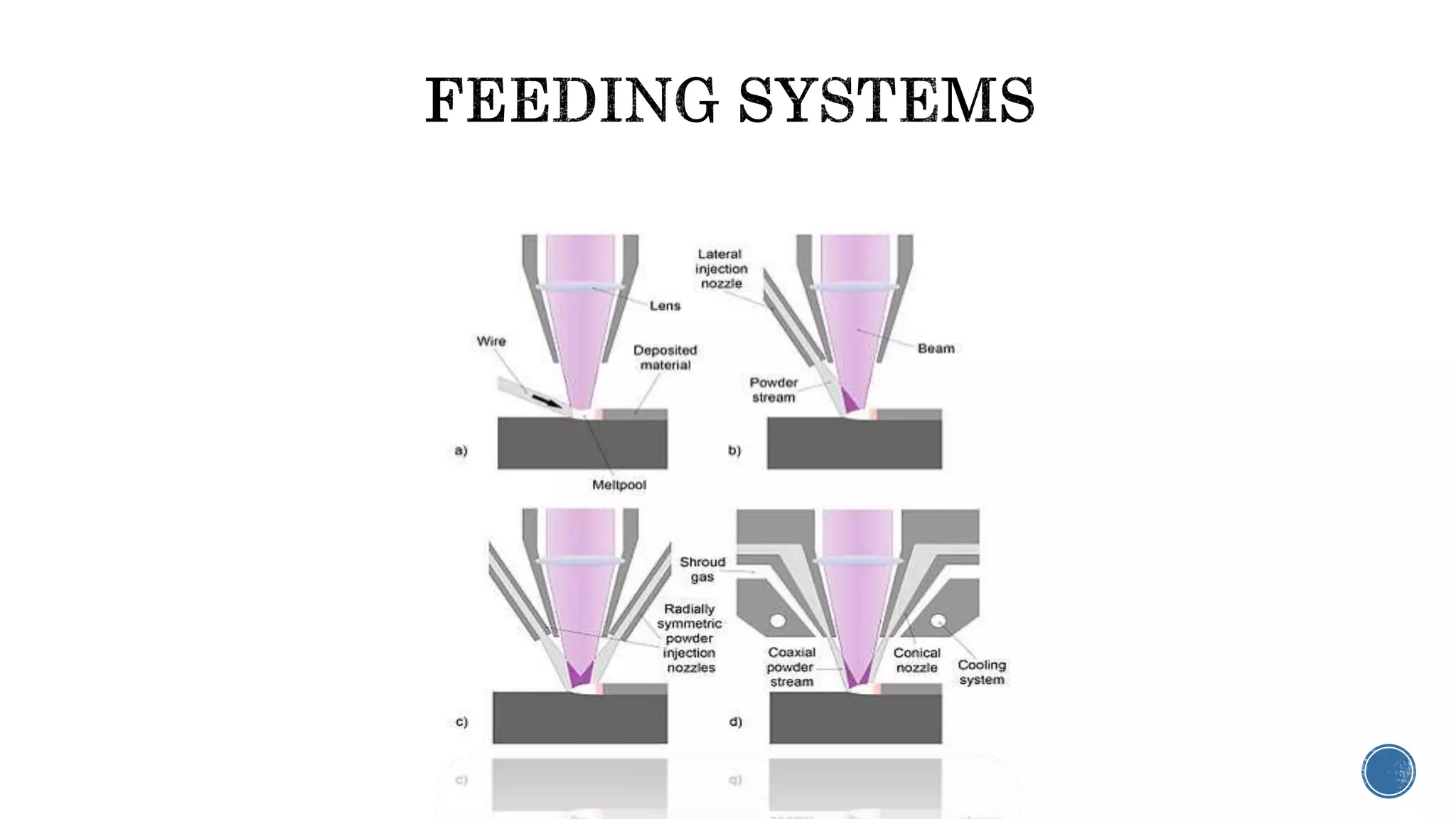

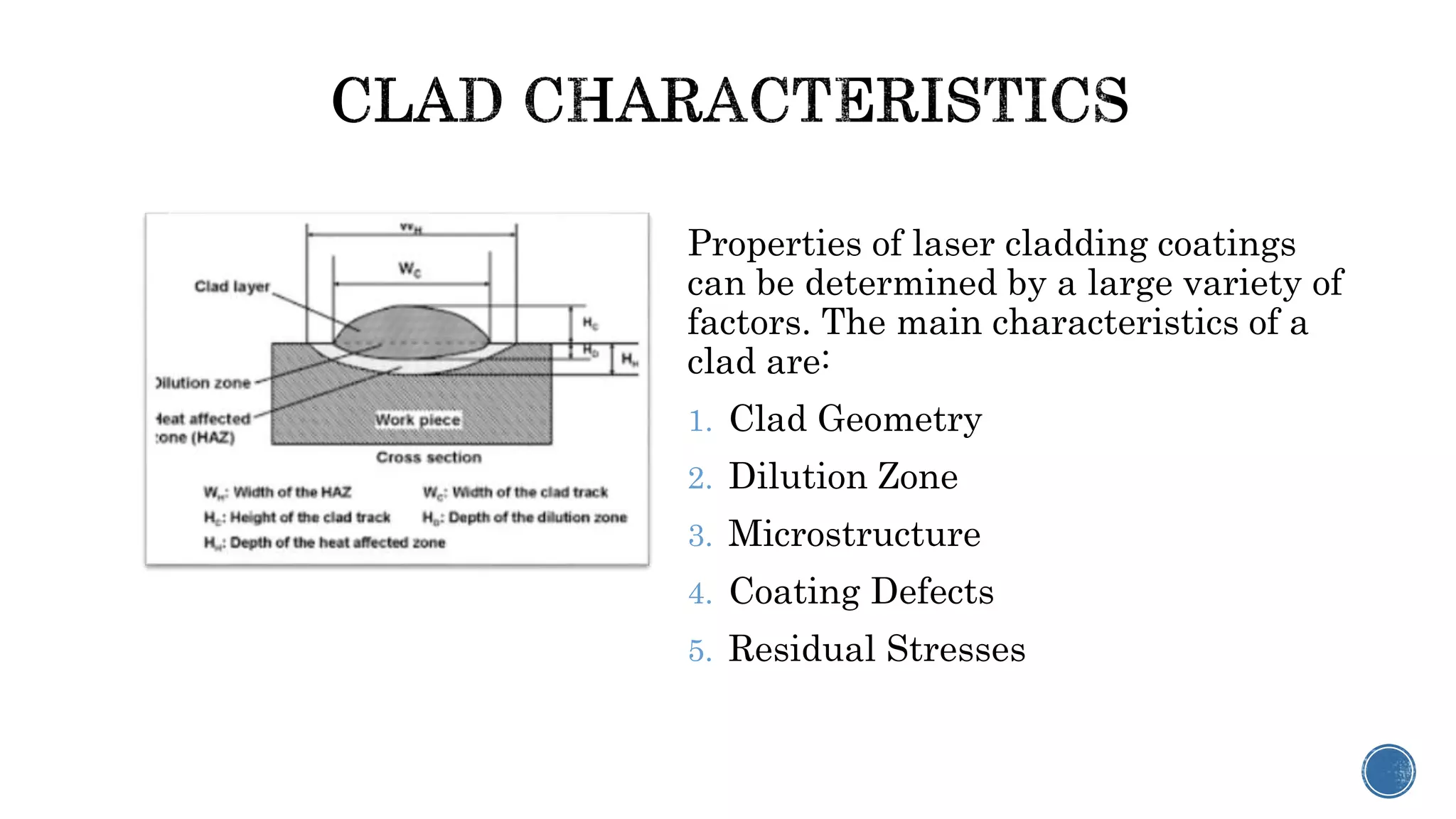

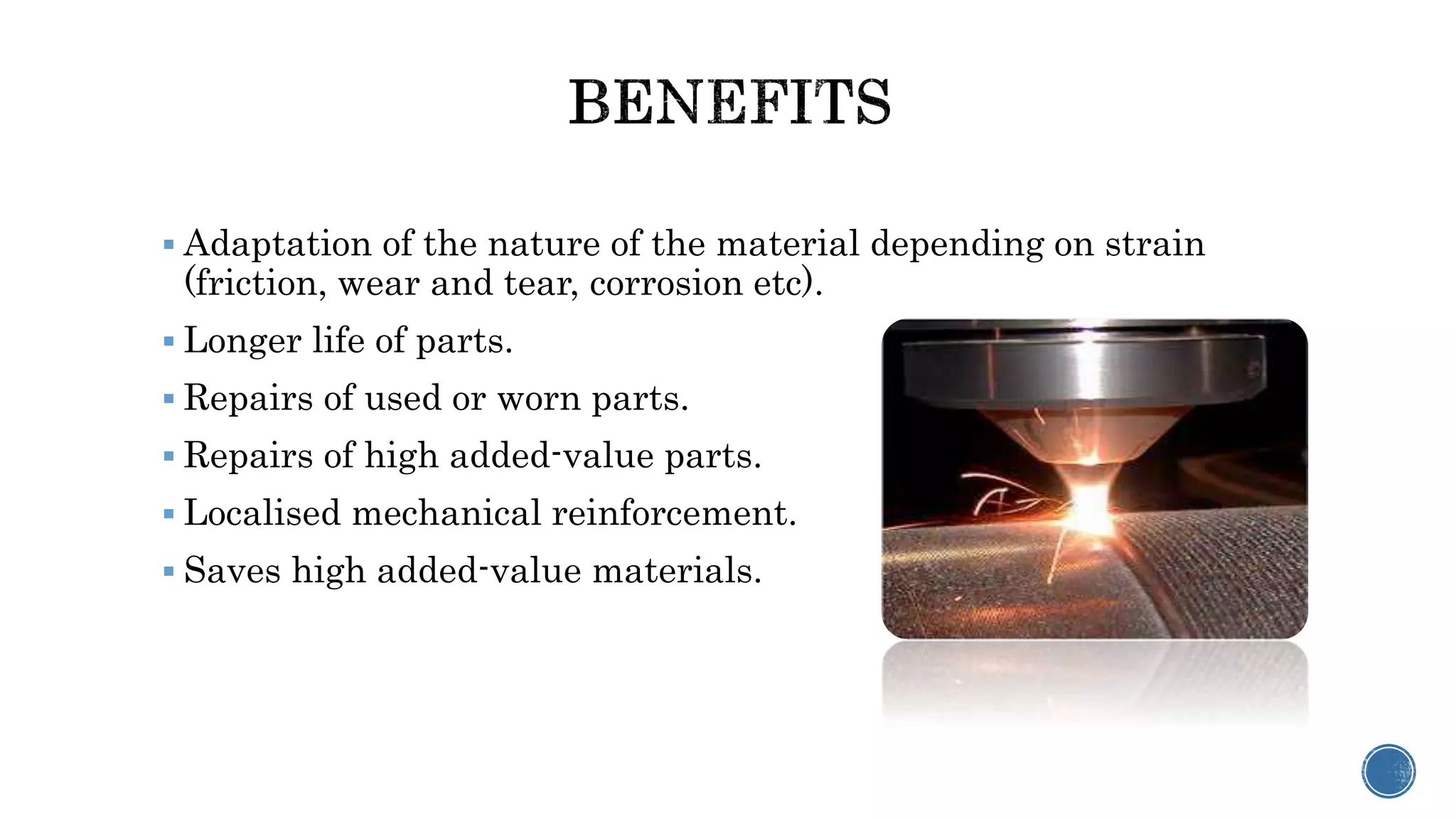

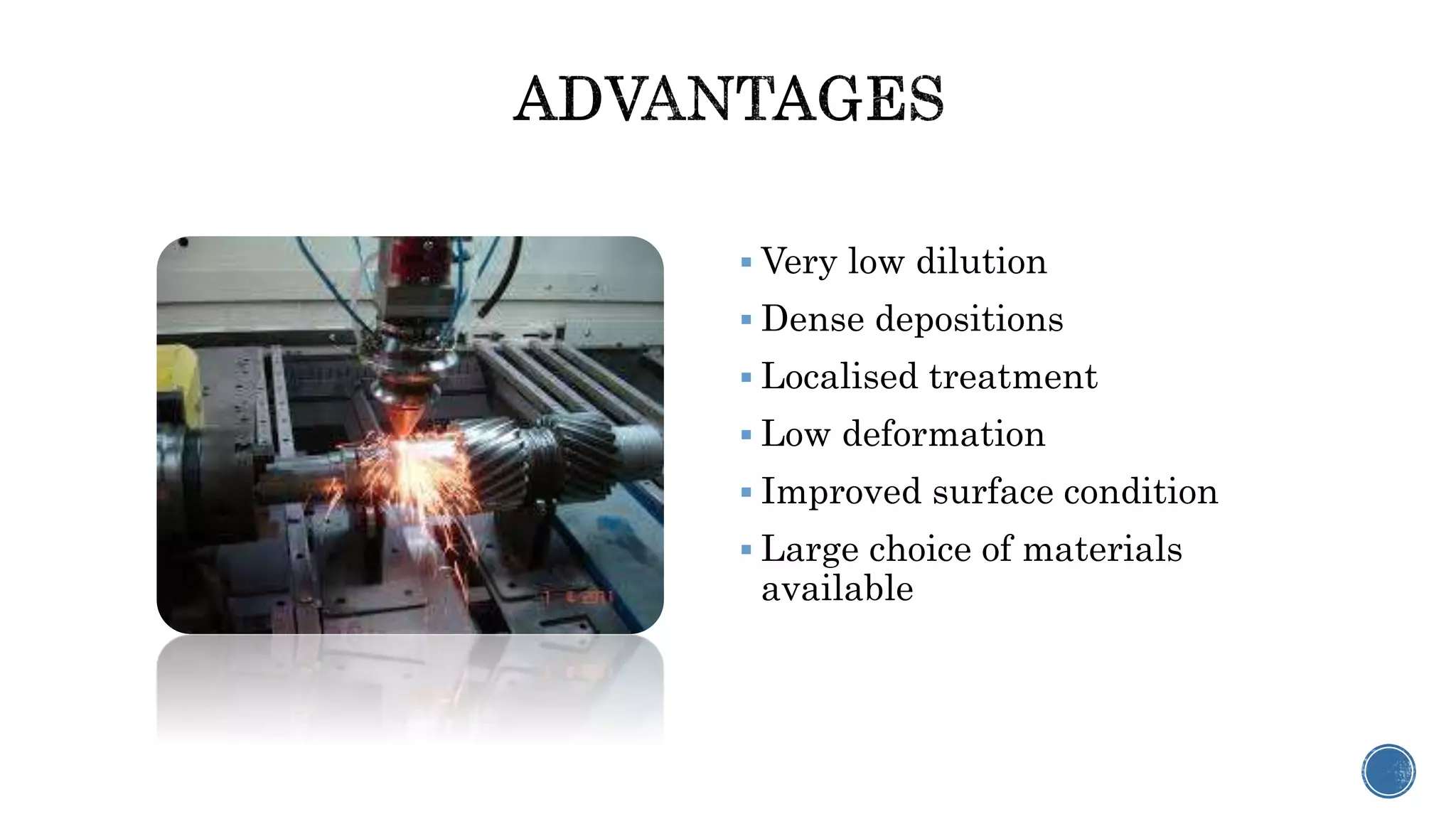

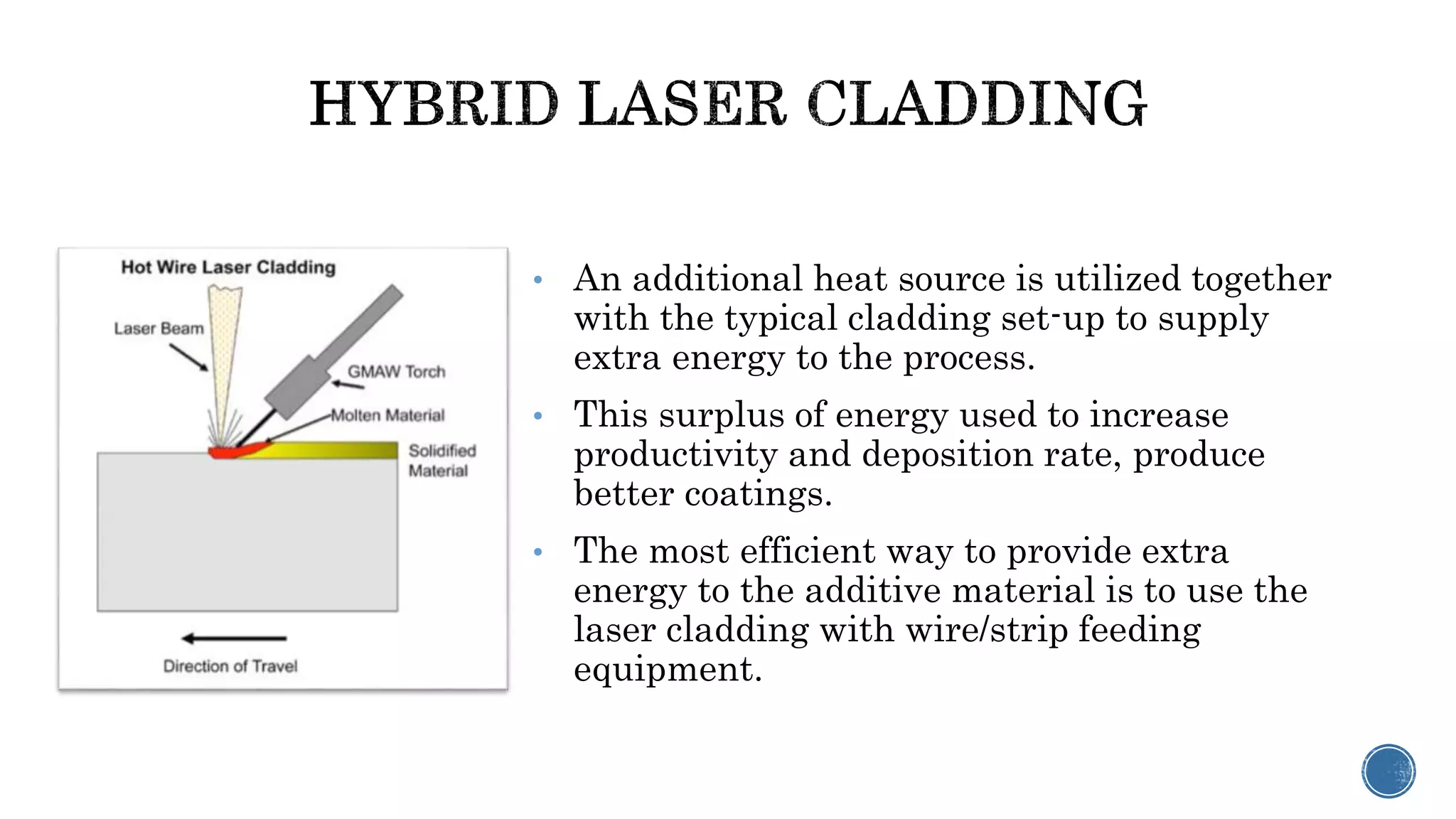

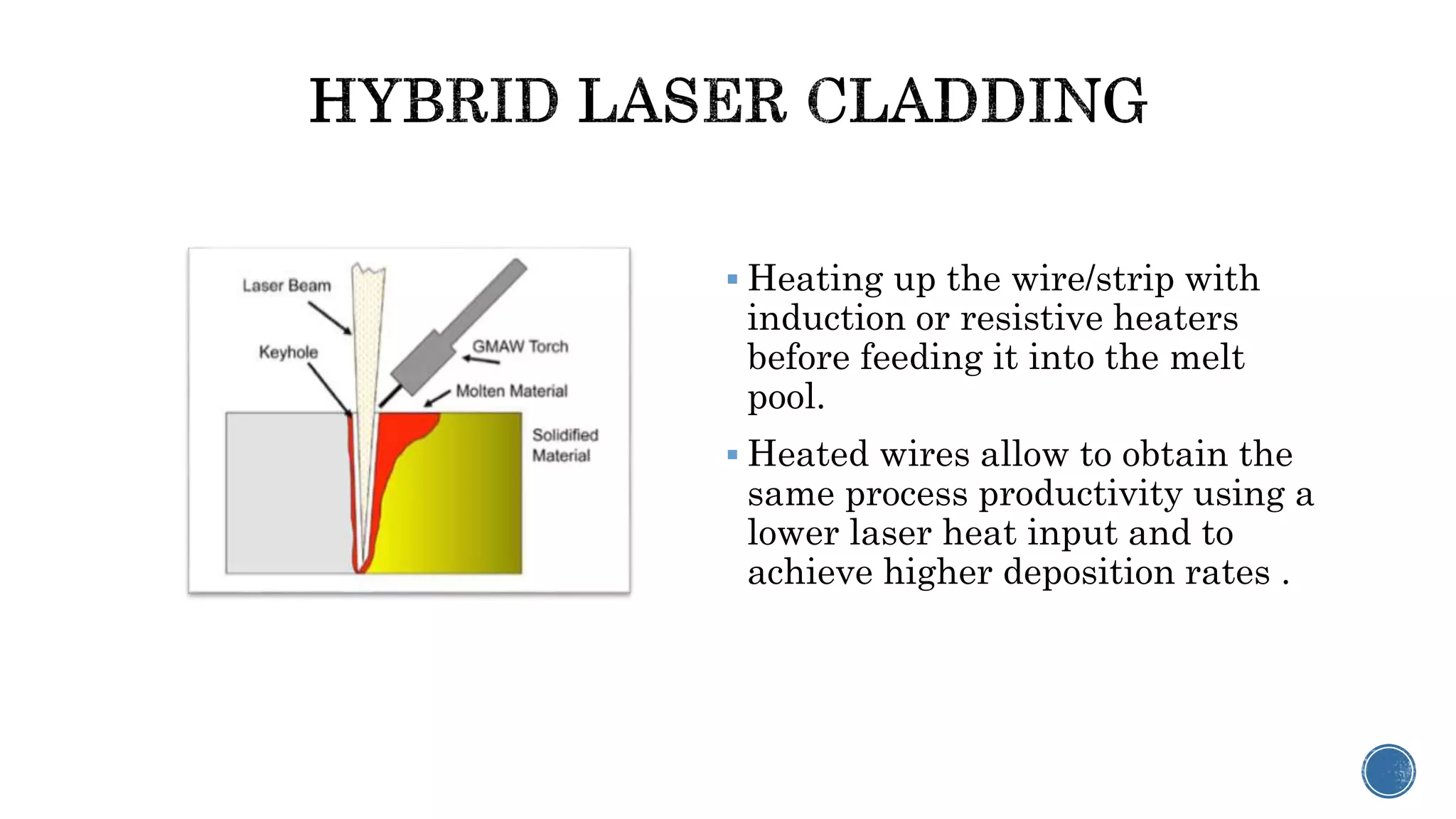

The document discusses laser cladding, a process involving the interaction of a focused laser beam with materials to melt and remove them, utilized for applications such as welding, cutting, and improving surface properties. It highlights various types of lasers, methods, and materials used in cladding, indicating advantages over traditional techniques, such as reduced heat-affected zones and improved surface conditions. Additionally, it covers industrial applications and challenges, including high setup costs and limited availability of this technology.

![1] Mechanical Bonding

2] Direct Adhered

3] Spot Bonding](https://image.slidesharecdn.com/lasercladding2-200515085819/75/Laser-cladding-10-2048.jpg)