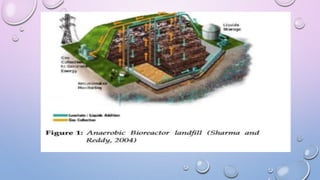

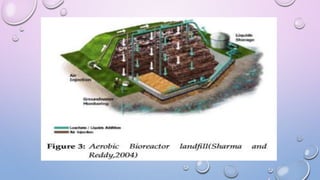

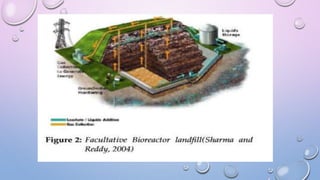

The document discusses landfill design and operations, emphasizing the critical role of landfills in municipal solid waste disposal and the evolution of waste management strategies. It details various landfill types, including sanitary and bioreactor landfills, and outlines key design, operation, and regulatory considerations for effective landfill management. Additionally, it highlights the importance of modern landfills as sustainable solutions in both developed and developing countries, where they serve as sources of materials and energy.